Digitalized detail visualizer of industrial X-ray negative with variable zooming ratio

A magnification, X-ray technology, applied in the field of industrial X-ray film digital detail observer, can solve the problems of high density, difficult to detail image information, large dynamic range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

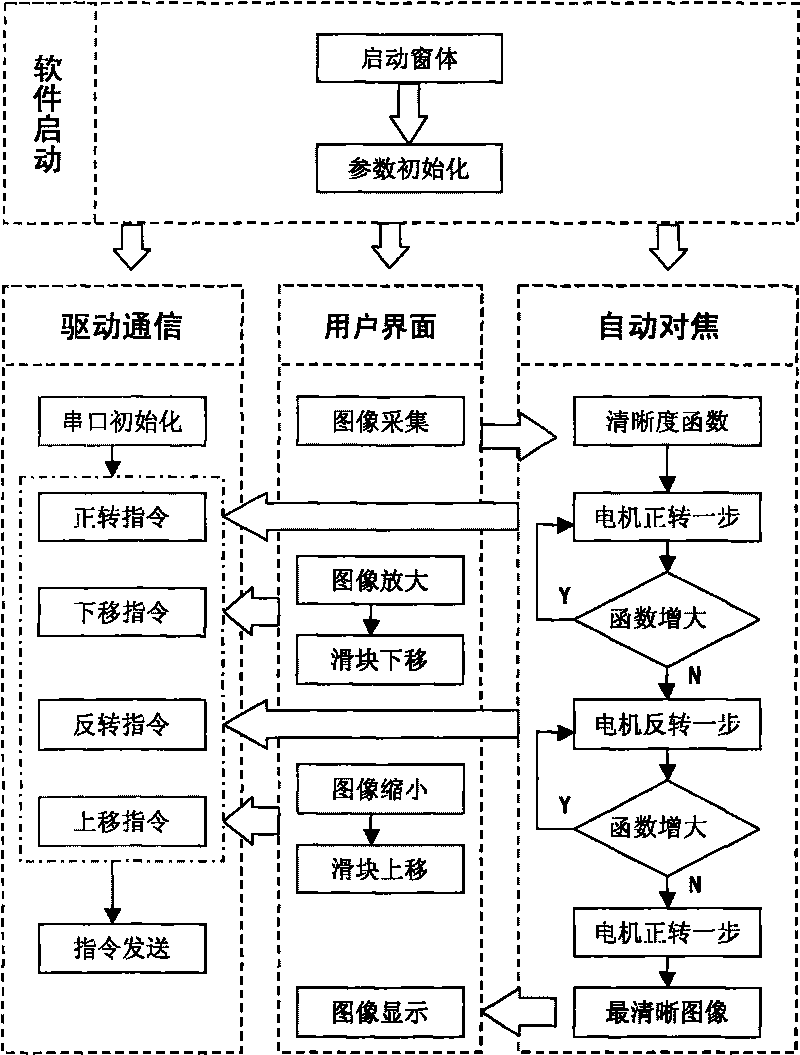

[0024] The present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

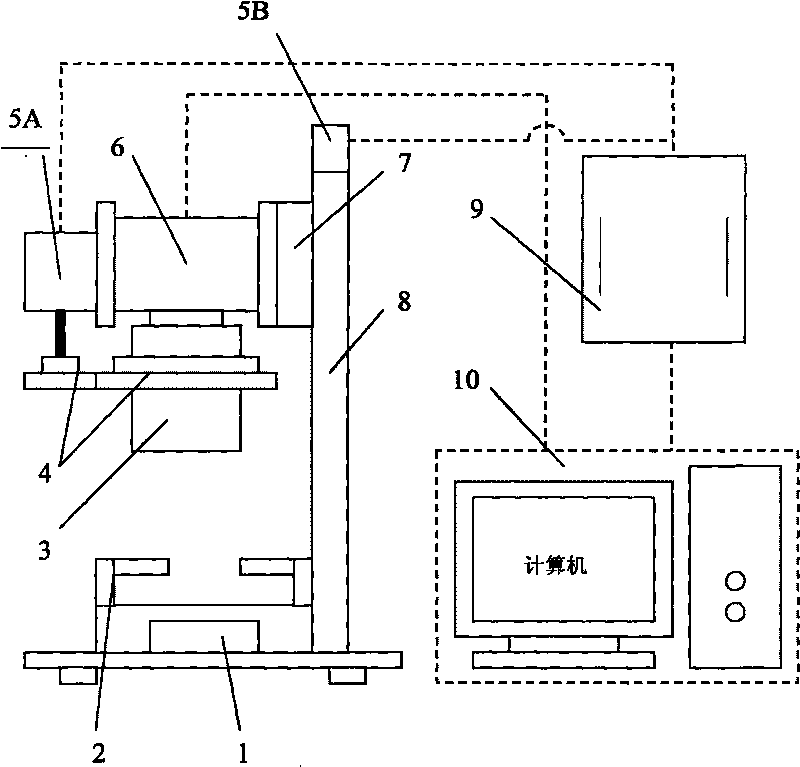

[0025] The components of this device are assembled as follows figure 1 As shown, each component in the figure is described in detail as follows:

[0026] 1. Light source 1 uses 4 high-power LEDs to form an area array white light source. Length 100mm, width 50mm, power 40w, driving voltage 60V-72V, maximum current 700mA, luminous flux 2800LM-3200LM;

[0027] 2. Condenser cover 2 adopts 100mm×50mm frosted glass or Fresnel lens. The frosted glass or Fresnel lens is installed on the upper surface of the square frame, and the frame is covered on the light source 1; the inner surface of the frame is white or has a reflector.

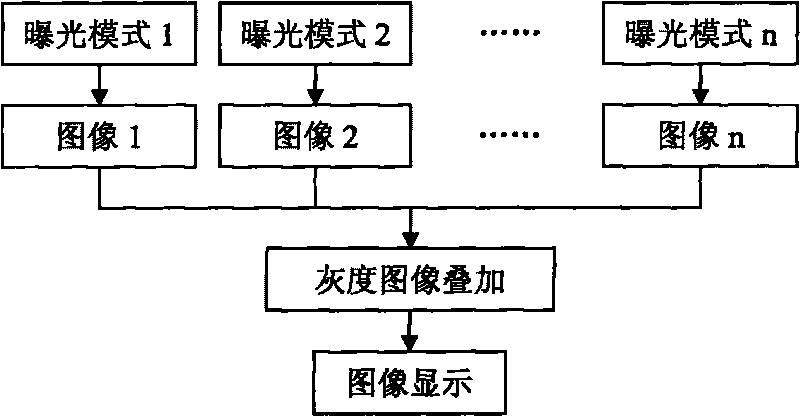

[0028] 3. There are two working modes for light source lighting, one is a low-current driving long-term lighting working mode; the other is a high-current instantaneous driving lighting mode, which is triggered synchronously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com