Hollow metal cone guiding and laser focusing device

A metal cone and hollow technology, applied in optics, optical components, instruments, etc., can solve the problems of short transmission distance, divergence, and reduced spot size of high-intensity, and achieve high damage threshold, large focus intensity, and high damage threshold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

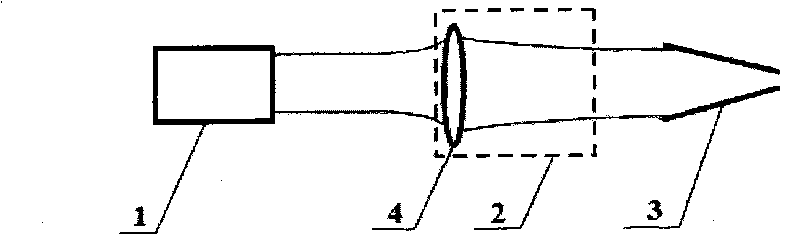

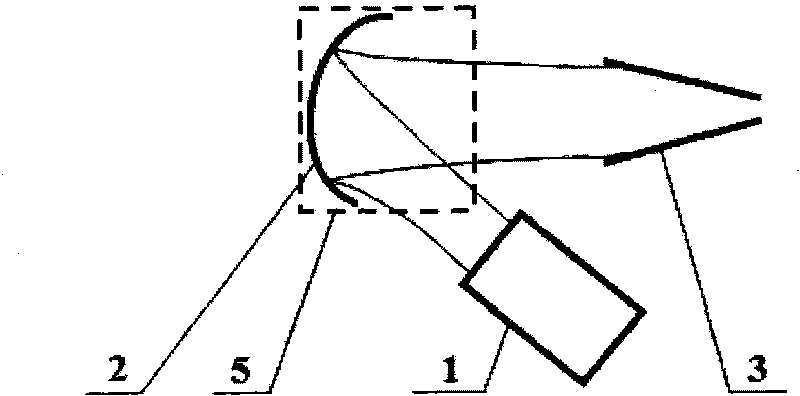

[0048] see first figure 1 , figure 1It is a schematic diagram of the structure and principle of Embodiment 1 of the device of the present invention. The device for guiding and focusing laser with a hollow metal cone of the present invention includes a laser 1 emitting a laser beam, and a light-condensing element 2 and a laser beam are arranged in sequence in the direction of the laser beam emitted by the laser 1 Hollow metal cone 3, the distance between the laser 1 and the light-condensing element 2 is equal to the focal length of the light-condensing element 2, the incident port of the hollow metal cone 3 is the large-diameter port and the The distance between the condensing elements 2 is equal to the focal length of the condensing elements 2 .

[0049] In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com