Soft-hard printed circuit board combination process

A combination of rigid-flex board and rigid-flex technology, which is applied in the manufacture of multi-layer circuits and the assembly of printed circuits with electrical components, can solve the problems of low liquid exchange rate, waste of copper, and failure to meet performance requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

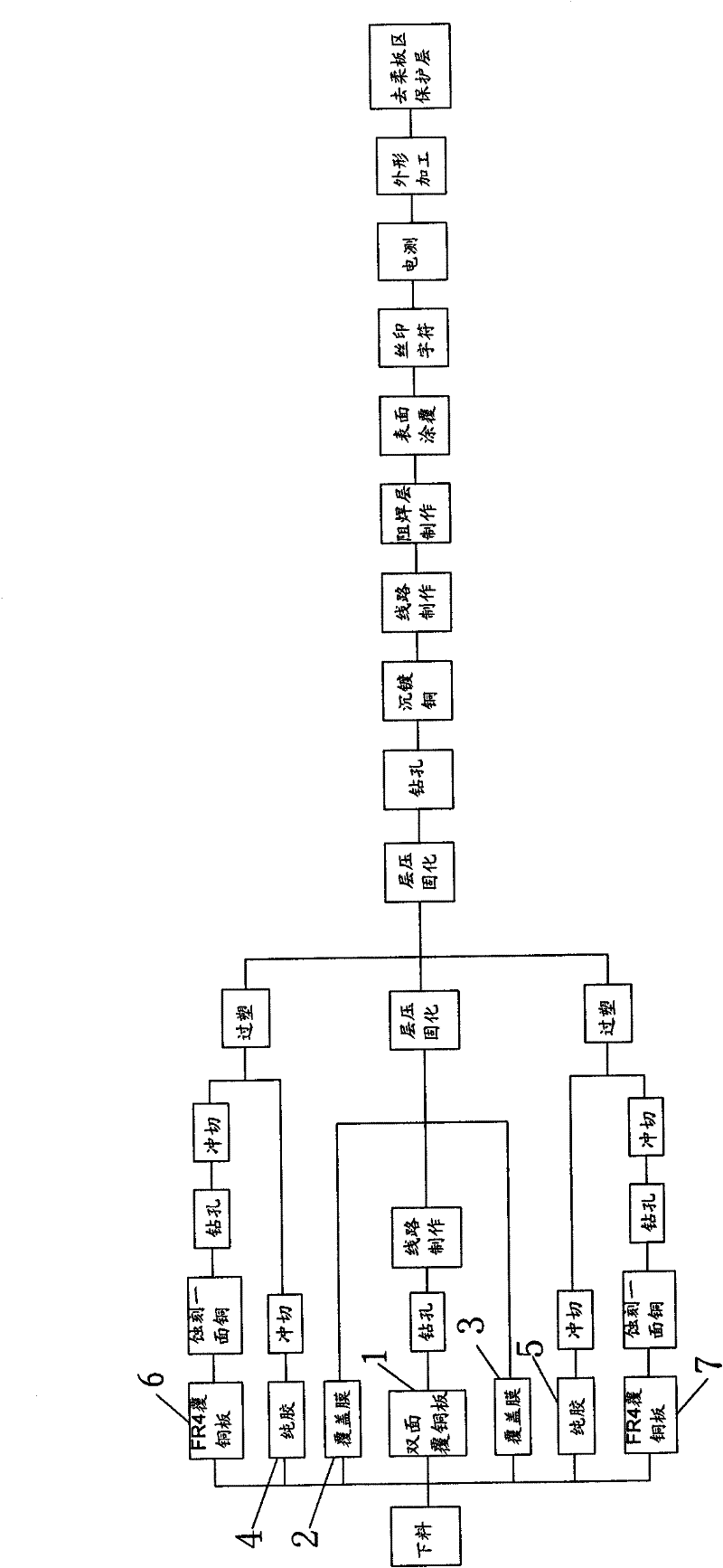

Method used

Image

Examples

Embodiment Construction

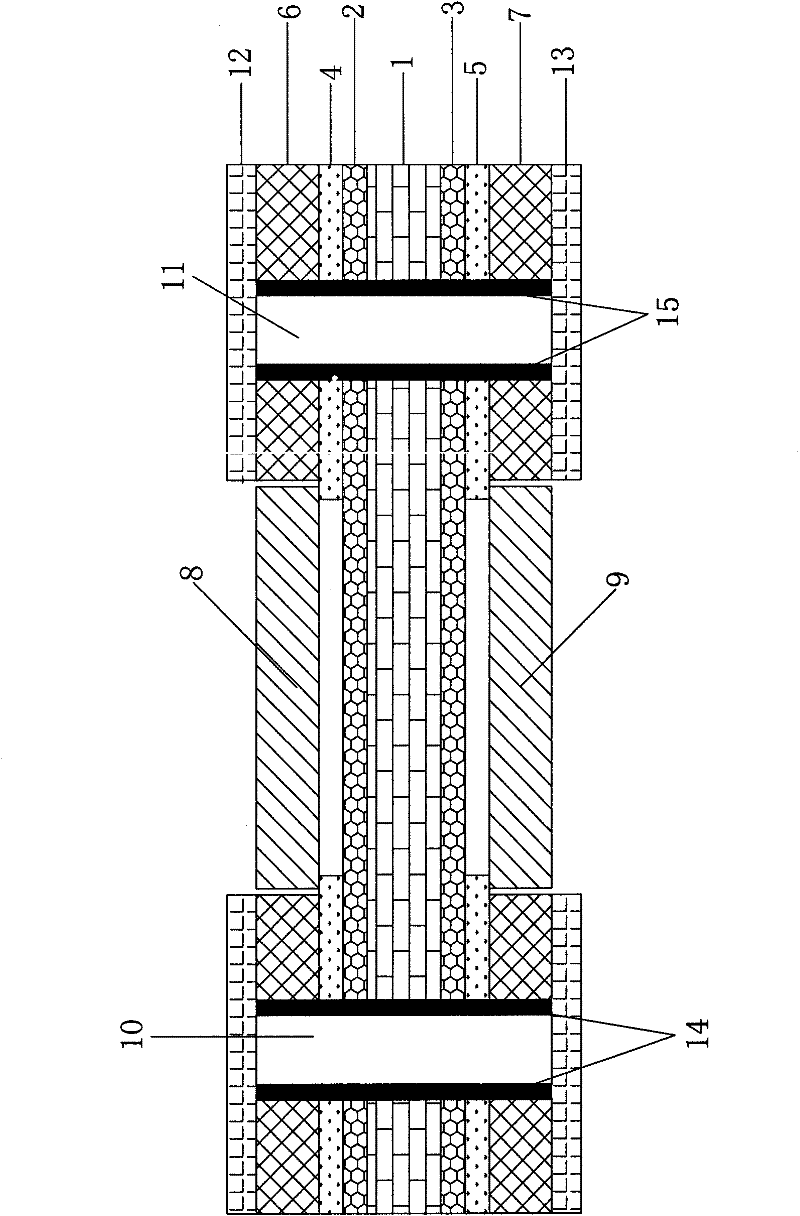

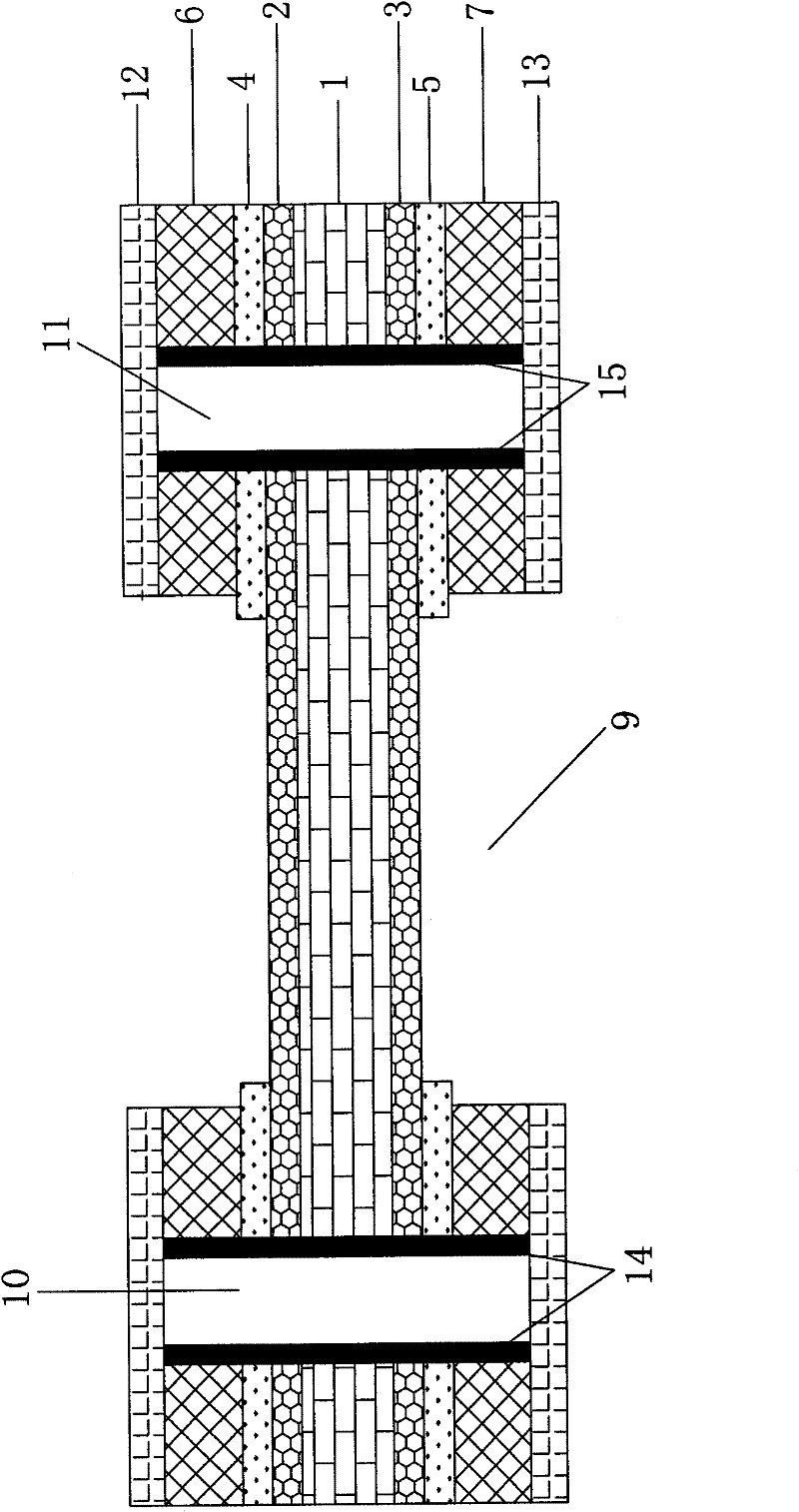

[0059] (2) Cover film punching: the surface cover film 29 and the bottom cover film 30 are the outer cover films of the product respectively, which need to be punched out of the corresponding windows of the outer layer circuit fingers, pads, etc., so that the circuit is connected to the outside world;

[0060] Single-sided copper-clad laminate drilling: the first inner layer single-sided copper-clad laminate 21, the second inner layer single-sided copper-clad laminate 22, the first outer layer single-sided copper-clad laminate 25 and the second outer layer single-sided copper-clad laminate 26 are the Each layer board, wherein the first inner layer single-sided copper clad laminate 21 and the second inner layer single-sided copper clad laminate 22 are inner flexible circuit boards, the first outer layer single-sided copper clad laminate 25 and the second outer layer single-sided copper clad laminate 26 For the outer flexible circuit board, first drill out the alignment hole for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com