Heat radiating method for circuit board

A heat dissipation method and circuit board technology, which are applied in the directions of printed circuits connected with non-printed electrical components, cooling/ventilation/heating transformation, etc., can solve the height of limited power devices, the limitation of circuit board component thickness, and the impossibility of height Great improvement and other problems, to achieve the effect of flexible arrangement, good heat dissipation effect, and lower height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims. The same components are denoted by the same reference numerals in the drawings.

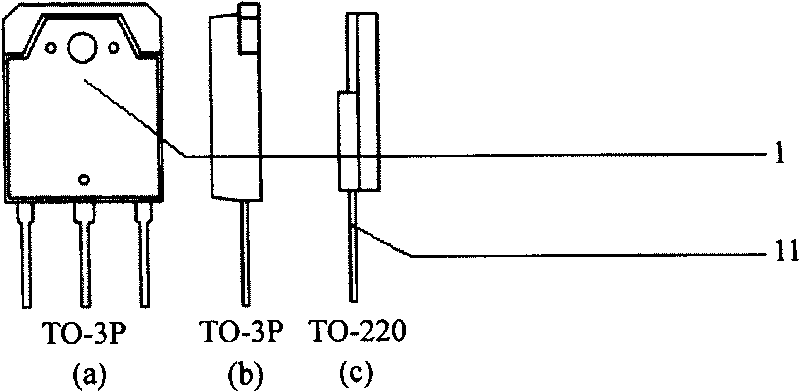

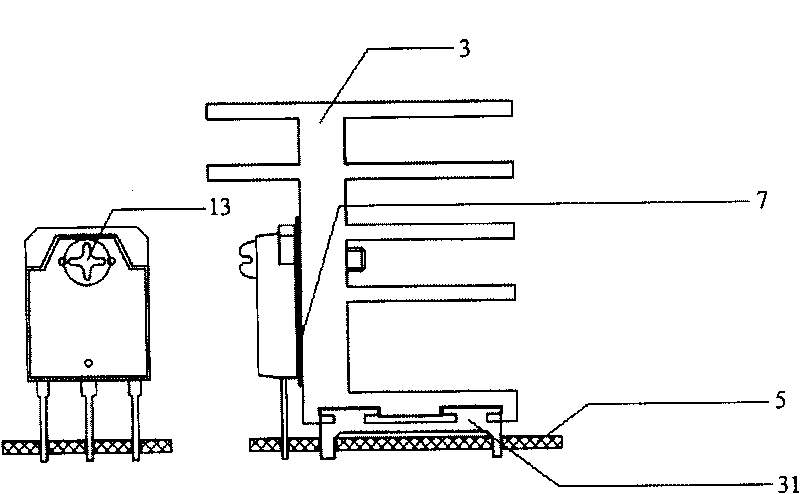

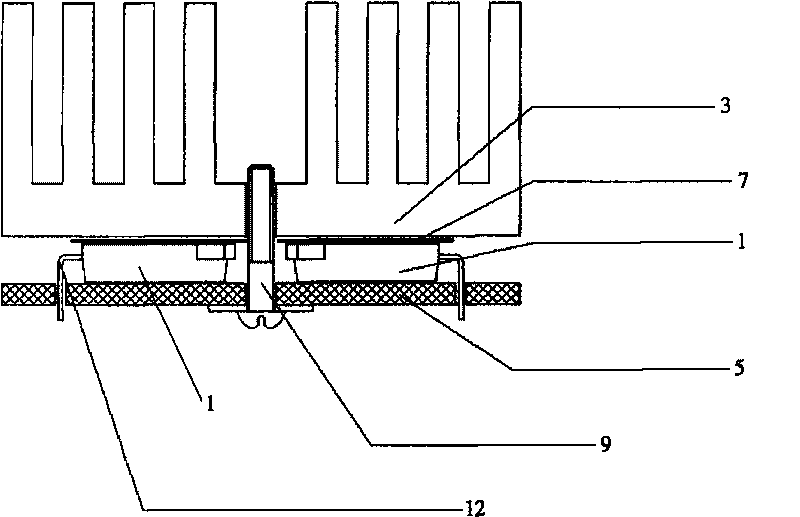

[0023] like image 3 As shown, it is a radiator installation method according to a preferred embodiment of the present invention. like image 3 As shown, the pins of the semiconductor power device 1 are bent at right angles to the direction of the PCB printed circuit board 5 according to the installation method. Place the power device 1 horizontally on the circuit board 5, with the side on which the heat sink 3 is mounted upward, and insert the pin 12 bent at a right angle into the circuit board 5, and then assemble the heat sink 3 corresponding to the corresponding mounting holes , wherein an insulating thermal pad 7 is provided between the power device 1 and the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com