Clean egg laminating machine

A technology of laminating machine and egg cleaning, applied in the direction of coating protective layer to preserve eggs, etc., can solve the problems of easy intrusion of microorganisms, accelerate egg spoilage, destroy egg shell structure, etc., and achieve the effect of prolonging storage and preservation time and saving materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

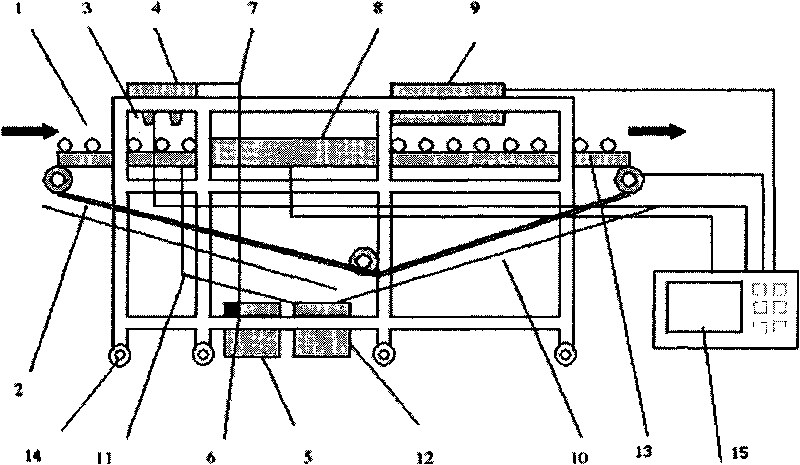

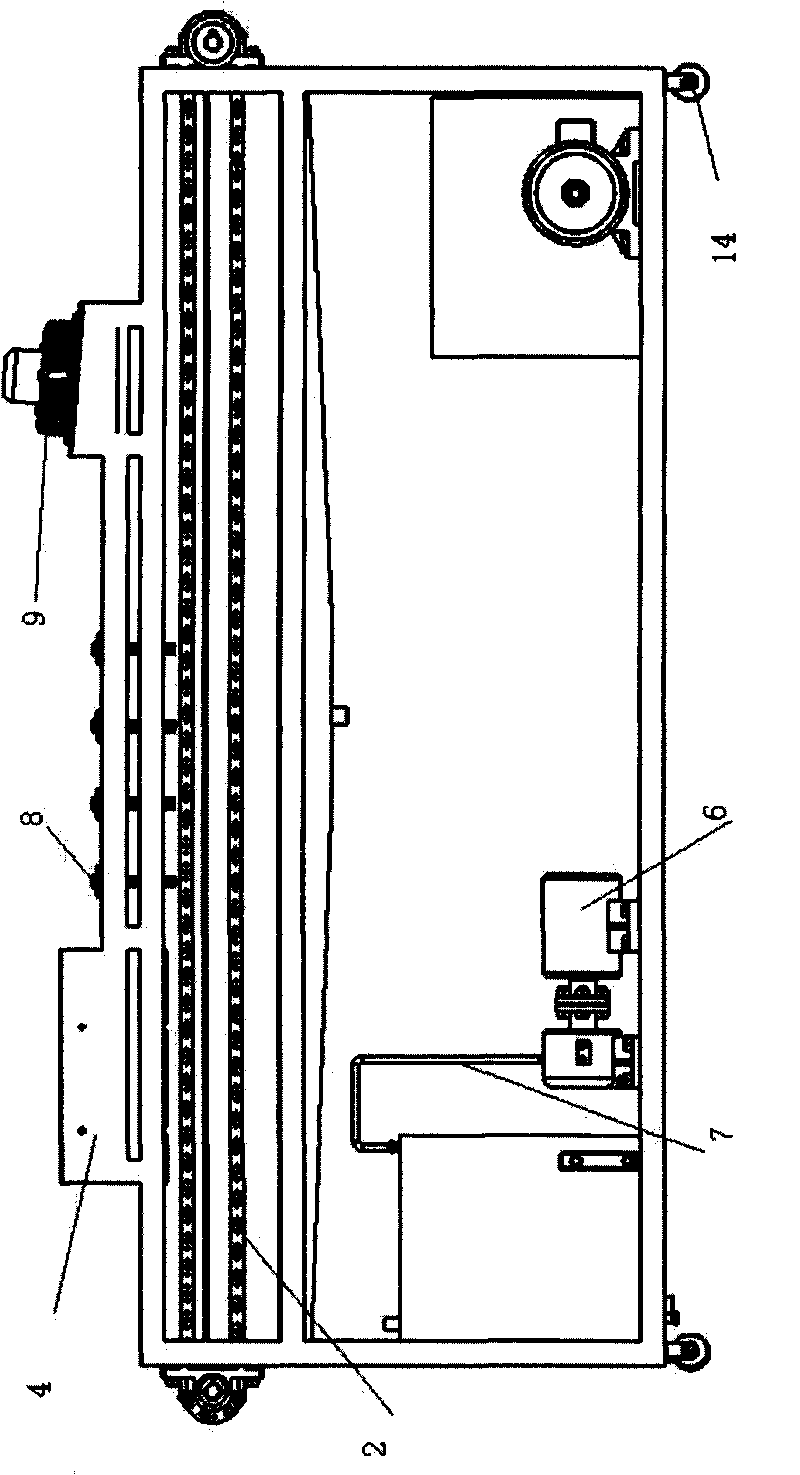

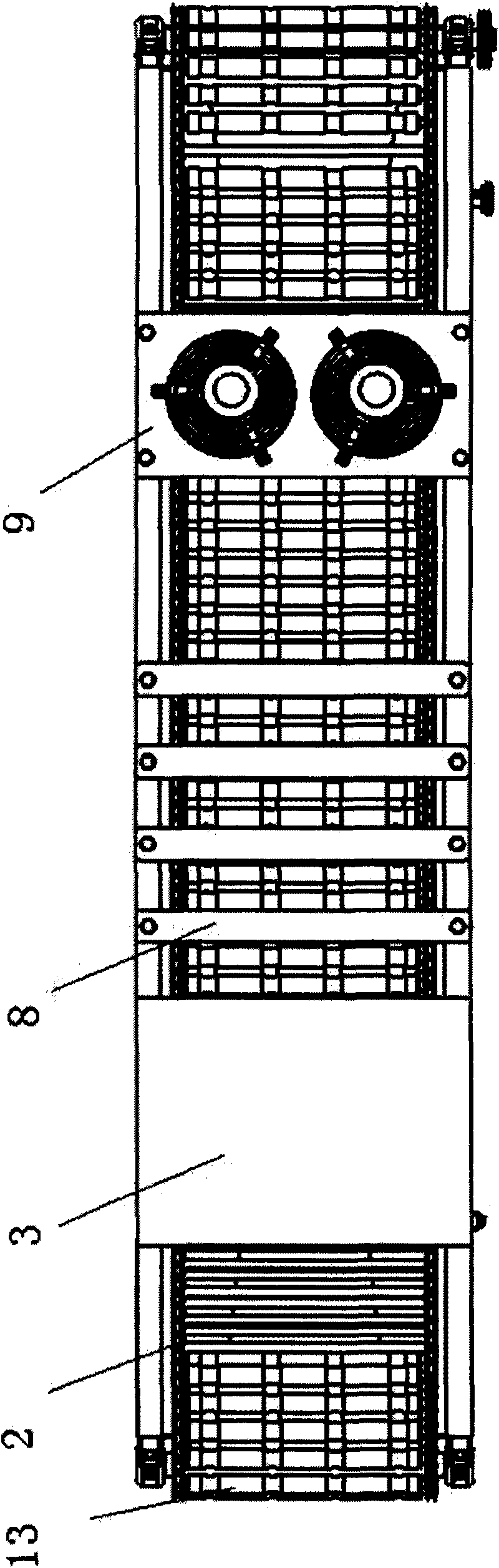

[0020] exist Figure 1 to Figure 4 In the shown embodiment, the poultry eggs 1 are placed on the cleaning egg coating machine and arranged in parallel on the multiple egg rollers 13 of the egg feeding chain 2. The distance between two adjacent egg rollers is constant, just to hold the poultry eggs, and to carry them into The egg chain 2 advances in a horizontal rolling manner and reaches a certain position. After the egg cleaning and coating machine senses that the eggs are in place, the expert control system issues an instruction. The preservative is sprayed on the poultry eggs passing by the set spray angle and spray volume, and the excess preservative is collected by the preservative return pipe 11 and flows back to the preservative return tank 12 to avoid the accumulation of the preservative in the spray film tank. In the process, if the preservative capacity is not enough in the spray film tank 4, then the pump 6 starts running and the preservative in the preservative sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com