Polymer/amphoterics/aqueous two-phase system, preparation method and application thereof

A surfactant, two-phase system technology, applied in separation methods, chemical instruments and methods, solvent extraction, etc., can solve problems such as high viscosity and unfavorable operation, and achieve good phase-forming effect, stable phase behavior, and phase-forming. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

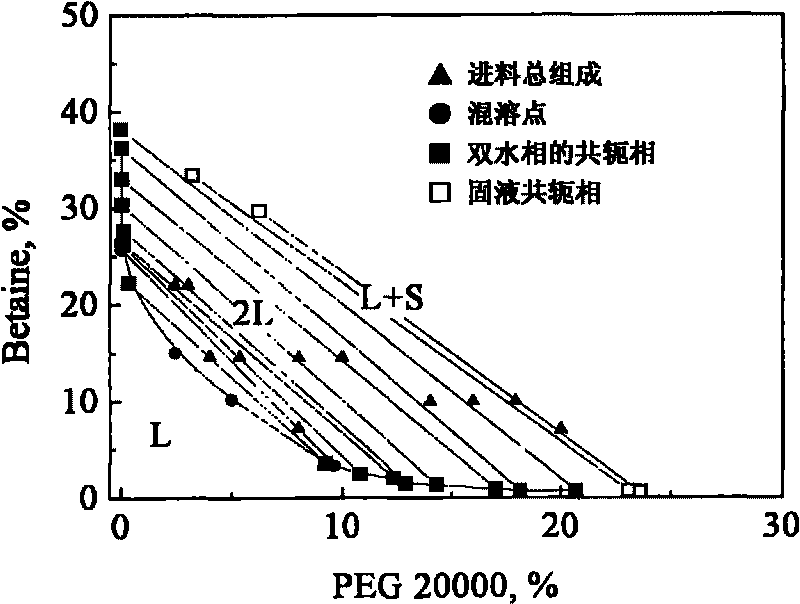

[0017] Add a certain amount of known concentration of polyethylene glycol (polyethylene glycol molecular weight is 20000, i.e. PEG20000) and cocamidopropyl betaine (Cocamidopropyl Betaine) in a 10ml glass centrifuge tube, add water to make the total weight of the system approx. 10g, turn it upside down and mix well, put it in a temperature-controlled centrifuge (25°C, 3000rpm, 30min), and put the centrifuged system in a 25°C constant temperature water bath for 24 hours to ensure the balance of the system and form Polyethylene glycol / cocamidopropyl betaine / water two-phase system, then take it out, record the volume of the two phases, and take out the upper and lower phases respectively.

[0018] Use an elemental analyzer (vario EL) to analyze the mass fractions of C, H, and N elements in the two-phase aqueous system: use the elemental composition of betaine molecules and polyethylene glycol molecules in the system to calculate the composition of the two phases , the results are...

Embodiment 2

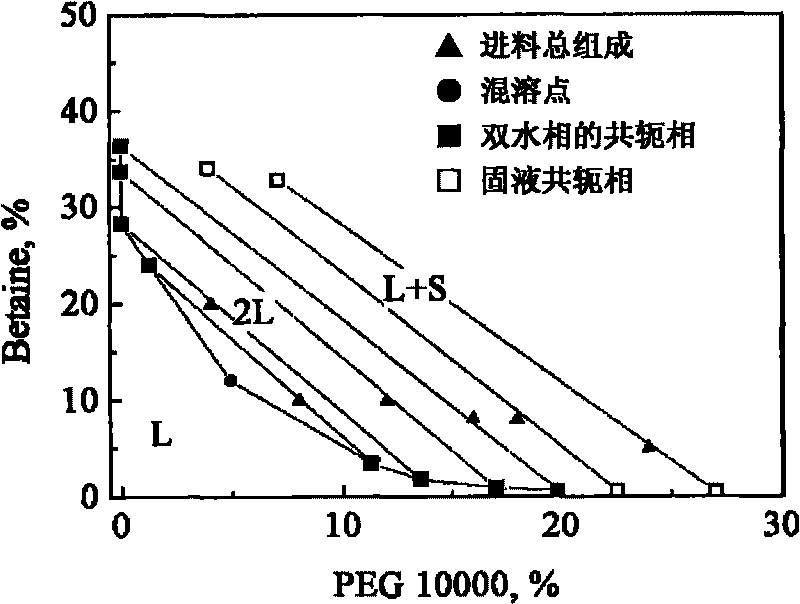

[0023] The two-phase phase equilibrium result of macrogol 10000 / cocamidopropyl betaine / water system, experimental procedure is exactly the same as embodiment 1, and the results are shown in Table 2 and figure 2 . The data in the figure and the table are all mass percentages.

[0024] Table 2 Phase equilibrium data of polyethylene glycol 10000 / cocamidopropyl betaine / water system, 25℃

[0025]

Embodiment 3

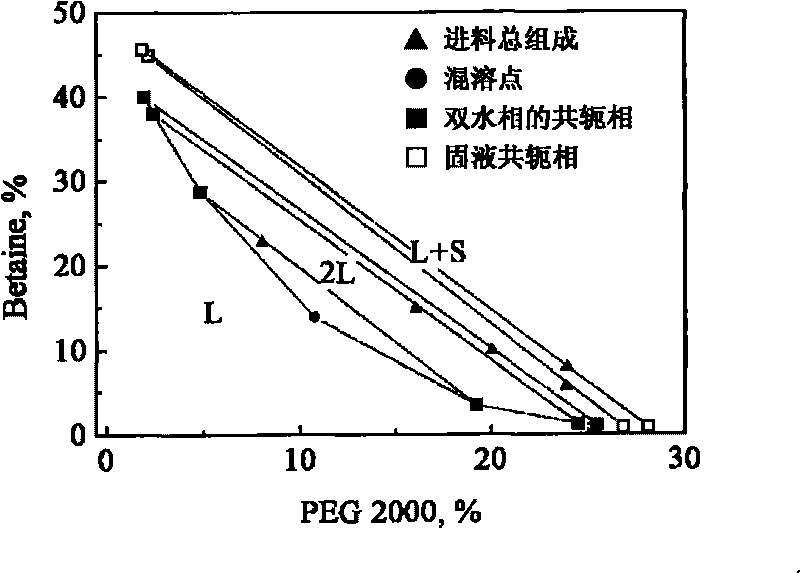

[0027] The two-phase phase equilibrium result of macrogol 2000 / cocamidopropyl betaine / water system, experimental procedure is exactly the same as embodiment 1, and the results are shown in Table 3 and image 3 . The data in the figure and the table are all mass percentages.

[0028] Table 3 Phase equilibrium data of polyethylene glycol 2000 / cocamidopropyl betaine / water system, 25℃

[0029]

[0030]

[0031] The phase diagram of the polyethylene glycol / cocamidopropyl betaine / water system of the present invention can be divided into a single-phase region, a two-phase region and a liquid-solid phase region. When the molecular weight of polyethylene glycol is greater than 10,000, the mutual solubility of the two phase-forming substances is small, and the connecting line is symmetrical, which is similar to the usual high polymer-high polymer type aqueous two-phase system.

[0032] In the polyethylene glycol / cocamidopropyl betaine / water two-phase aqueous system in the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com