Method and device for cleaning membrane

A technology for cleaning devices and membranes, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve uneconomical problems, improve the effect, and solve the effect of biological clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

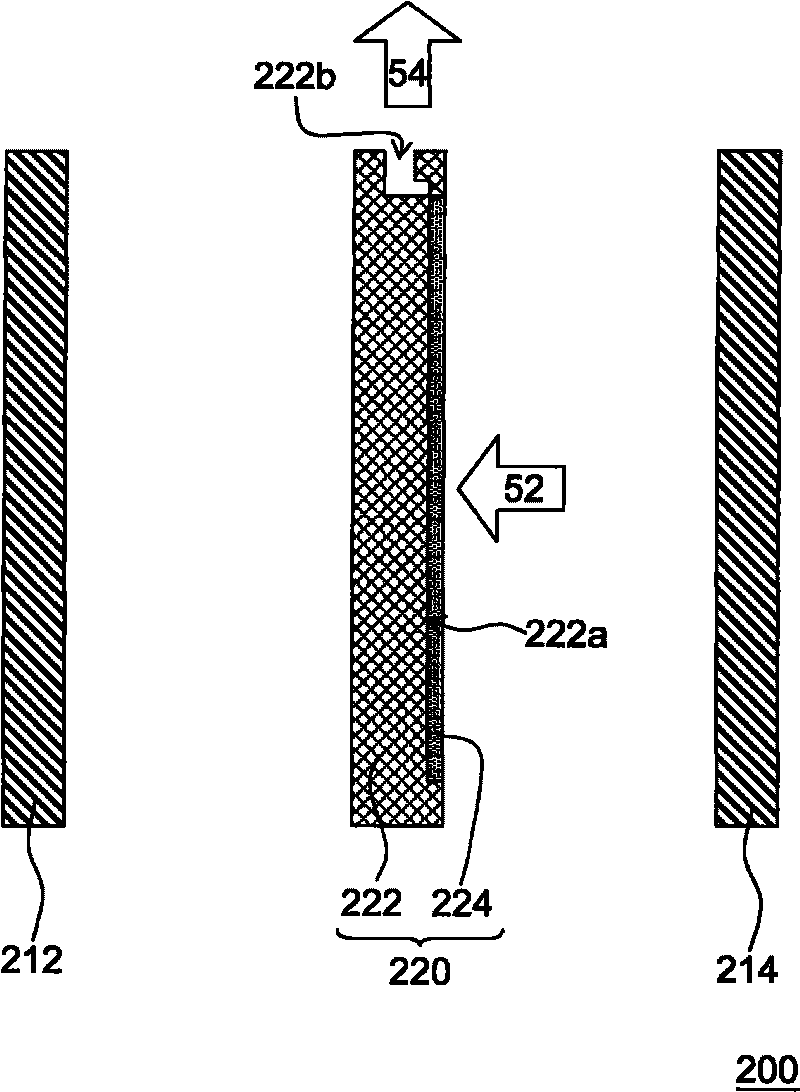

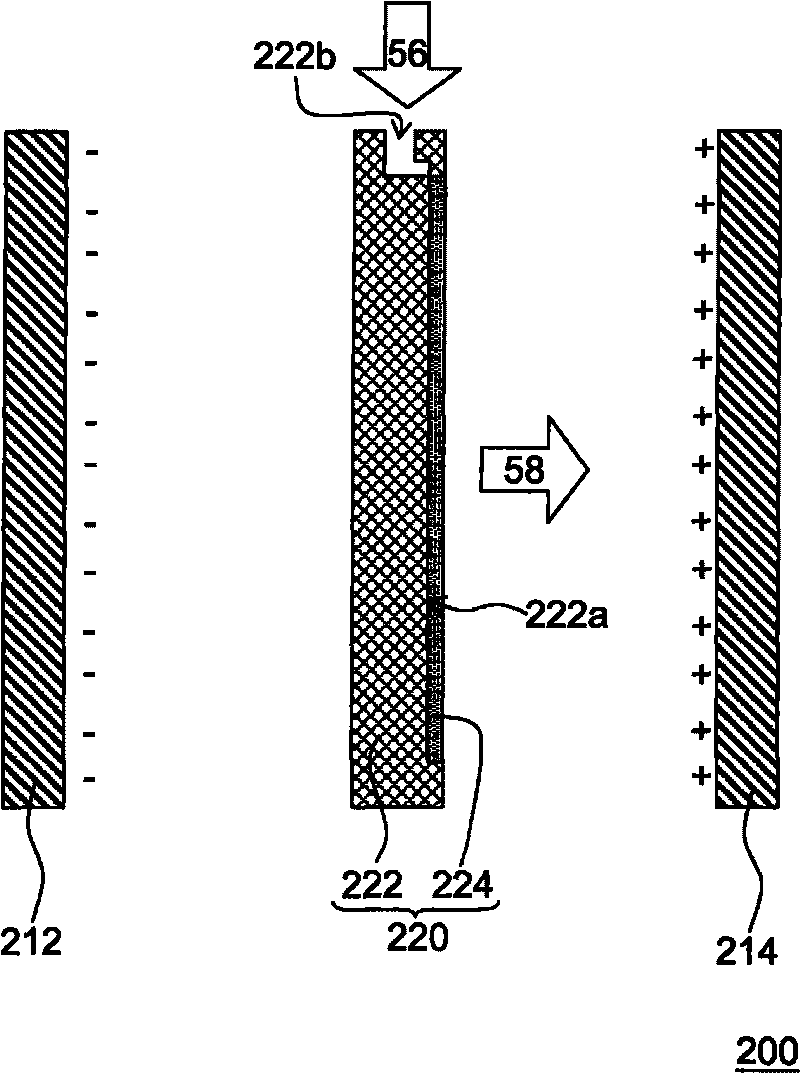

[0045] Figure 2A and Figure 2B It is a schematic cross-sectional side view of a film cleaning device according to an embodiment of the present invention. Please refer to Figure 2A , The film cleaning device 200 of the present invention includes two electrode plates 212 , 214 and a filter unit 220 , wherein the filter unit 220 is disposed between these electrode plates 212 , 214 . also. The filter unit 220 includes a support plate 222 and a membrane 224 , and the membrane 224 is disposed on the support plate 222 and is used for filtering raw water to produce purified water.

[0046] In this embodiment, the membrane 224 can be a reverse osmosis (Reverese Osmosis, RO) membrane, but the present invention does not limit the type of the membrane 224, for example, the membrane 224 can also be a nanofiltration (Nanofiltration, NF) membrane, ultra Filtration (Ultrafiltration, UF) membrane, microfiltration (Microfiltration, MF) membrane or other suitable types of filtration membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com