Ultrasonic-assisted rubber seed oil extraction method

A rubber seed oil, auxiliary extraction technology, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of easily damaged olive pomace oil quality, long extraction time, unfriendly environment, etc., to shorten Enzymolysis and hydration flocculation time, convenient preparation, good oil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

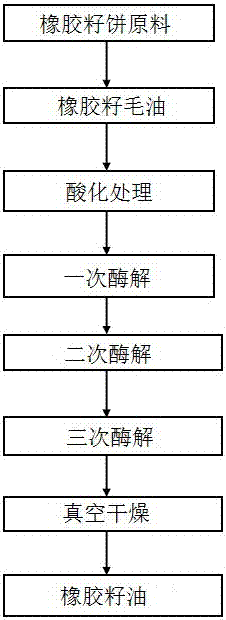

Method used

Image

Examples

Embodiment 1

[0031] Select the rubber seed kernels for cold pressing until the oil content is 10%, and obtain the rubber seed cake; continue to dry the rubber seed cake until the moisture content is 4%, to obtain the rubber seed cake raw material; add n-hexane to the rubber seed cake raw material Ultrasonic-assisted extraction, and separation to obtain crude rubber seed oil, then vacuum-dry the crude rubber seed oil to obtain crude rubber seed oil. %, the phospholipid content is 2318.85mg / Kg; heat the rubber seed crude oil to 80°C in a water bath, add 0.13% of the oil weight and citric acid with a concentration of 40%, and after being homogeneously mixed, stir under the assistance of ultrasonic waves And insulated and retained for acidification reaction for 10 minutes, after the rubber seed crude oil was acidified, acidified rubber seed oil was obtained; the pH of the acidified rubber seed oil was adjusted to 4.5, and phospholipase A1 of 0.008% of the acidified rubber seed oil quality was a...

Embodiment 2

[0033] Select the rubber seed kernels for cold pressing until the oil content is 12.5% to obtain the rubber seed cake; continue to dry the rubber seed cake until the moisture content is 5% to obtain the rubber seed cake raw material; add n-hexane to the rubber seed cake raw material Ultrasonic-assisted extraction, and separation to obtain crude rubber seed oil, then vacuum-dry the crude rubber seed oil to obtain crude rubber seed oil. %, the phospholipid content is 3426.10mg / Kg; heat the rubber seed crude oil to 75°C in a water bath, add 0.115% of the oil weight and citric acid with a concentration of 45%, and after being homogeneously mixed, stir under the assistance of ultrasonic waves And insulated and retained for acidification reaction for 15 minutes, after the rubber seed crude oil was acidified, acidified rubber seed oil was obtained; the pH of the acidified rubber seed oil was adjusted to 4.9, and phospholipase A1 of 0.010% of the acidified rubber seed oil quality was...

Embodiment 3

[0035] Select rubber seed kernels for cold pressing until the oil content is 15% to obtain rubber seed cake; continue to dry the rubber seed cake until the moisture content is 4.5% to obtain rubber seed cake raw material; add n-hexane to the rubber seed cake raw material Ultrasonic-assisted extraction, and separation to obtain crude rubber seed oil, then vacuum-dry the crude rubber seed oil to obtain crude rubber seed oil. %, the phospholipid content is 2872.48mg / Kg; heat the rubber seed crude oil to 85°C in a water bath, add 0.10% of the oil weight and citric acid with a concentration of 35%, and after homogeneous mixing, stir under the assistance of ultrasonic waves And keep it warm for acidification reaction for 10 minutes. After the rubber seed crude oil is acidified, the acidified rubber seed oil is obtained; the pH of the acidified rubber seed oil is adjusted to 4.7, and phospholipase A1 of 0.009% of the acidified rubber seed oil quality is added for ultrasonication. Aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com