Automatic-control oil pipe dry-type paraffin removal unit

An automatic controller and oil pipe technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of high labor intensity and serious environmental pollution, and achieve the effect of reducing labor intensity, saving water resources, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

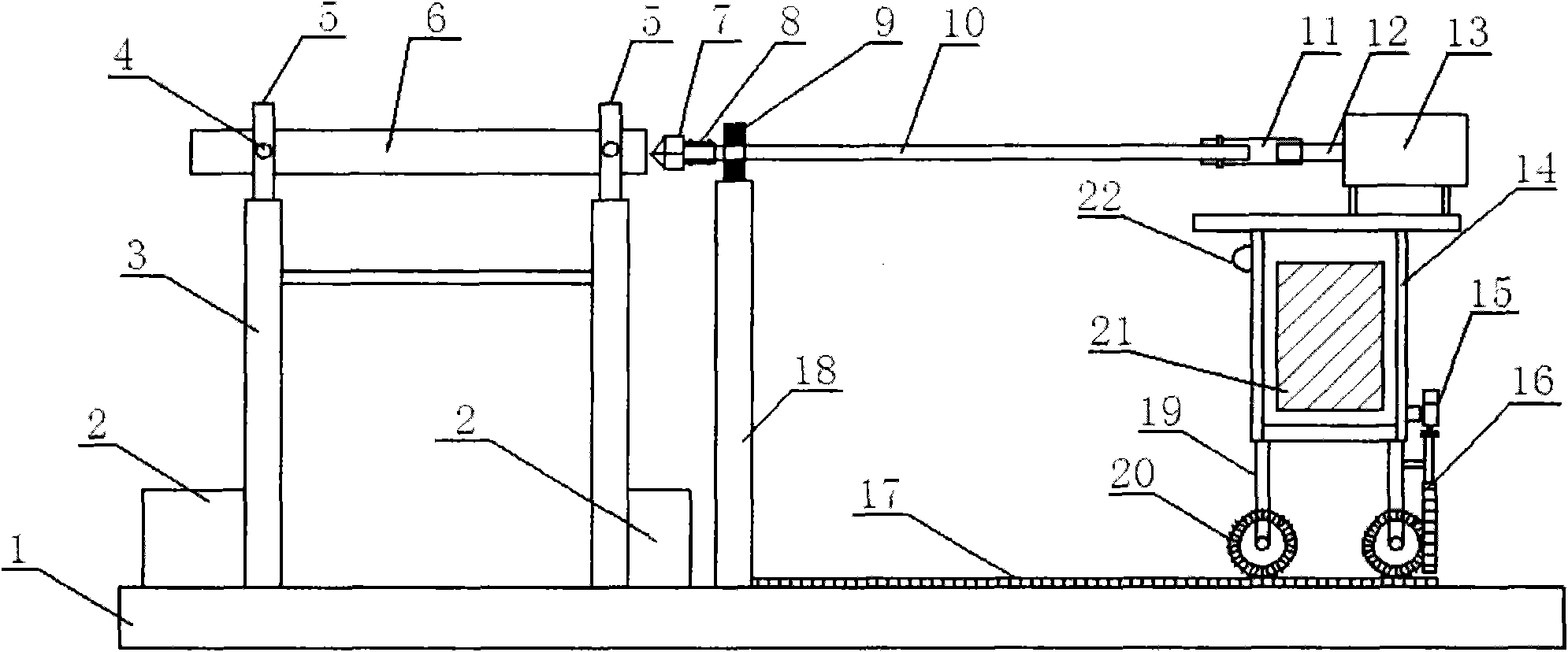

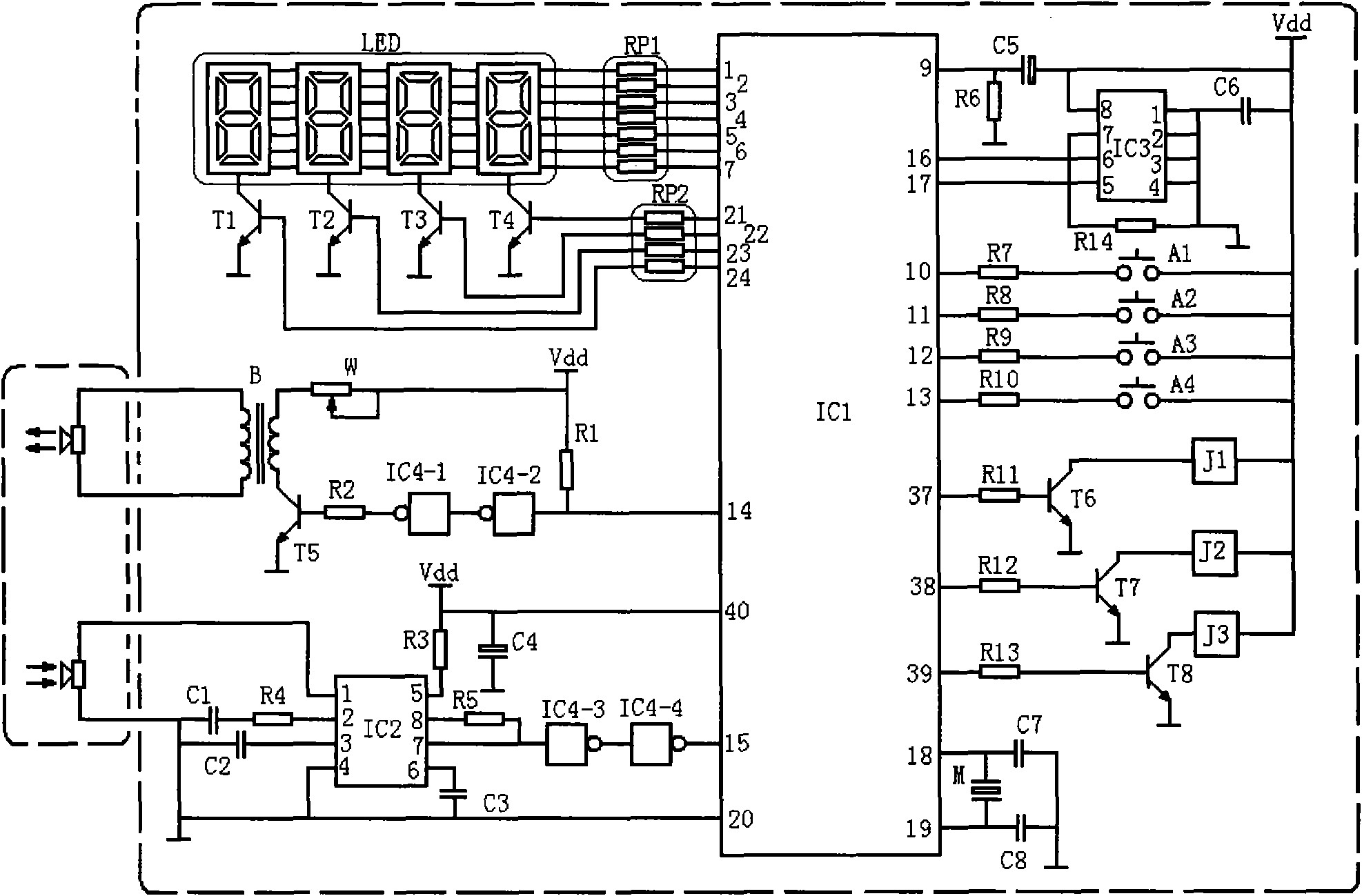

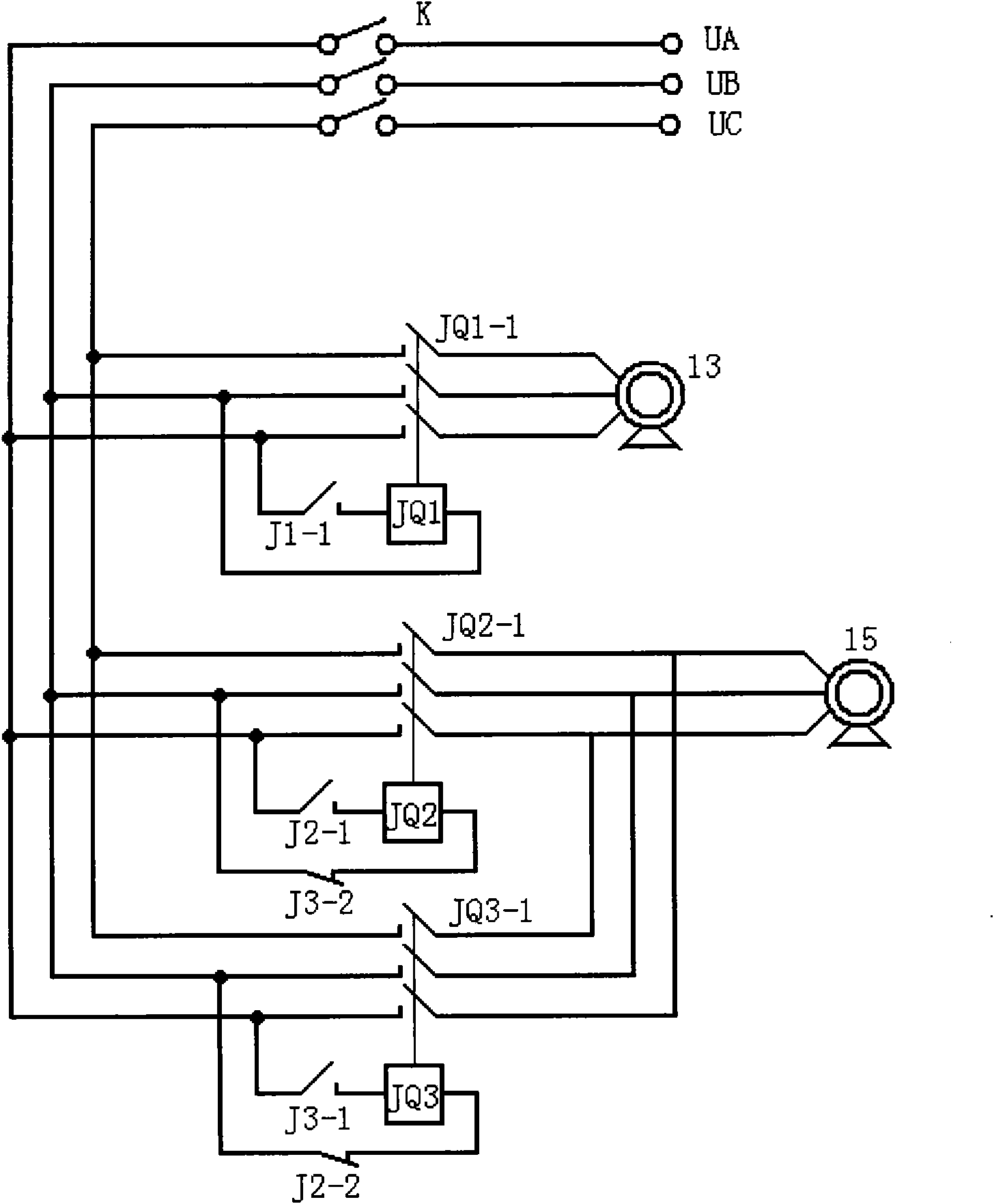

[0010] Such as Figure 1-Figure 3 As shown, an automatic control oil pipe dry wax removal device includes a base, oil pipe fixing bracket, support frame, drill bit, drill pipe, propulsion motor, drive motor, rack slide rail, workbench, worm, gear, oil storage boxes and automatic controllers. One end of the base 1 with a rectangular structure on the upper plane is provided with an oil pipe fixing bracket 3, and the other end is provided with a rack slide rail 17, and a support frame 18 is provided in the middle. The oil pipe fixing bracket 3 is a frame structure, and the upper end is provided with an oil pipe. Fixture 5, its lower end is connected with the base 1, the oil pipe clamp 5 is provided with fixing bolts 4, the top of the support frame 18 is provided with a sliding bearing 9, its lower end is connected with the base 1, and the workbench 14 is a box type structure, the upper part is provided with a drive motor 13, the power shaft 12 of the drive motor 13 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com