Method for preparing colored cementitious material

A binder and color technology, which is applied in the field of colored binders, can solve the problems of high production cost, many production equipment, and low production efficiency, and achieve the effects of low production and operation costs, reduced production costs, and few production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

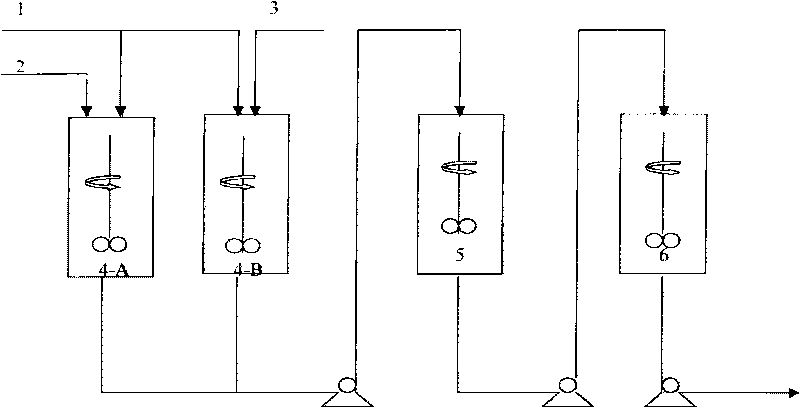

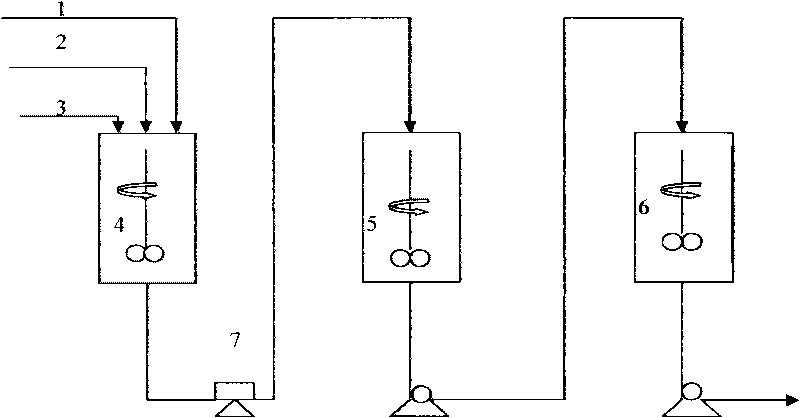

Method used

Image

Examples

Embodiment 1

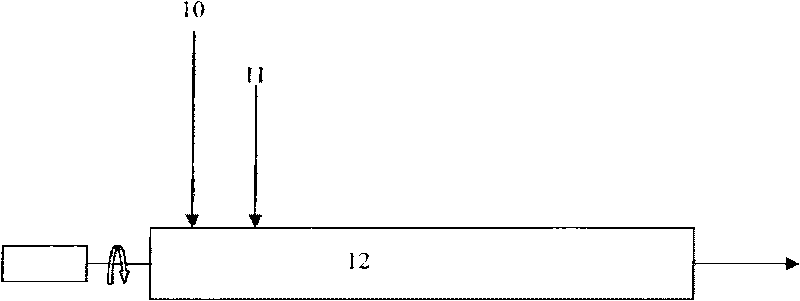

[0022] according to image 3 The equipment and method shown, petroleum resin and SBS are fed into the extruder 12 through the feeding port 10, and the refined oil extracted from the lubricating oil solvent is fed into the extruder 12 through the feeding port 11. 10 cycles of mixing, extruding twice, and then cooling to obtain the final color cement product. The main properties of the product are shown in Table 1.

Embodiment 2

[0024] According to the process of Example 1, the extruder 12 was operated at 170° C. and 2 MPa, and the output temperature was directly lowered to obtain the final color cement product. The main properties of the product are shown in Table 1.

[0025] The main properties of the color cementitious material product of the embodiment of table 1

[0026] project

[0027] The product quality complies with the provisions of "Sinopec Enterprise Standards".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com