Diagonally driven connecting rod pressure drive mechanism

A technology of transmission mechanism and connecting rod, which is applied in the field of pressure transmission and connecting rod pressure transmission mechanism, which can solve the problems of large lateral force of the slider and inconspicuous force increase effect, and achieve long working stroke, high positioning and repeat positioning accuracy , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

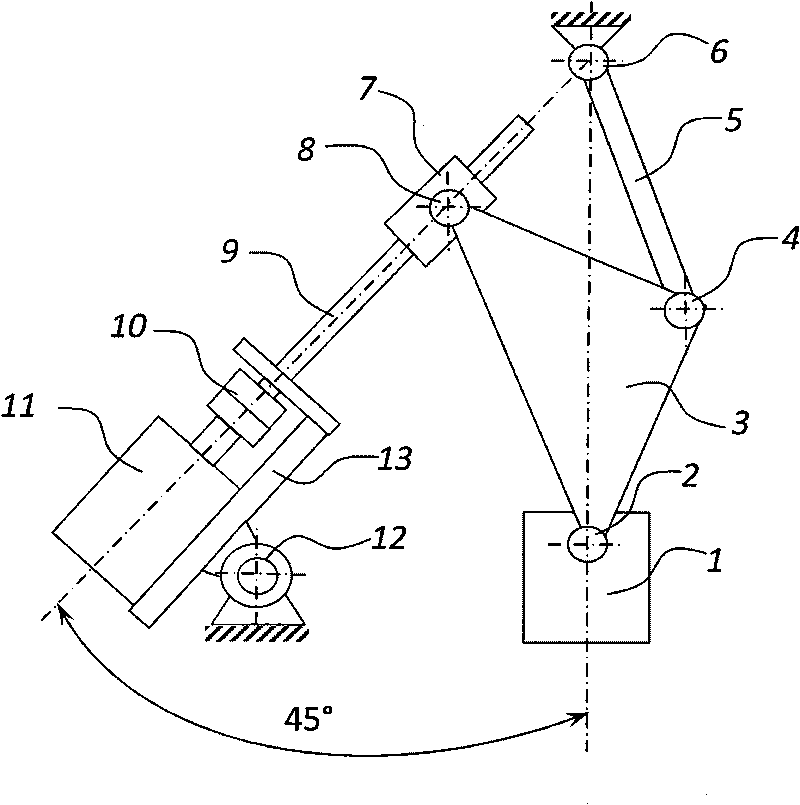

[0025] Embodiment one: if figure 1 As shown, this embodiment includes a servo motor 11, a connecting rod 5,

[0026] The connecting hinge 4, the driving hinge 8 and the slider hinge 2 are fixed on the triangular plate 3, and the connecting line of the axes of the three hinges forms an isosceles right triangle, and the axis of the connecting hinge 4 is located at the intersection of the two right angle sides of the isosceles right triangle, and the driving hinge 8 The shaft center and the slider hinge 2 shaft centers are respectively located at the intersection of the right-angled side and the hypotenuse;

[0027] One end of the connecting rod 5 is connected to the frame through the upper beam hinge 6, and the other end of the connecting rod 5 is connected to the triangular plate 3 through the connecting hinge 4. The distance between the axis center of the upper beam hinge 6 and the axis center of the connecting hinge 4 is the same as It is equal to the distance between the ax...

Embodiment 2

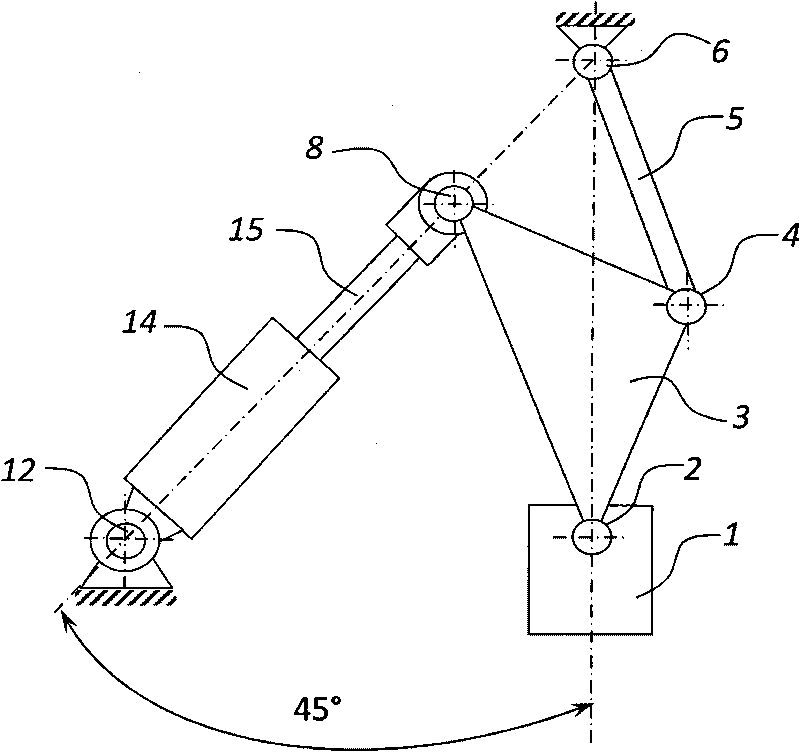

[0033] Embodiment two: if figure 2 As shown, in the present embodiment, the driving source is a hydraulic cylinder 14 driven by a hydraulic system, the end of the piston rod 15 of the hydraulic cylinder 14 is hinged with the drive hinge 8, and the bottom end of the hydraulic cylinder 14 is hinged with the fixed support hinge 12; The angle between the axis of the rod 15 and the vertical is 45 degrees. Driven by hydraulic pressure, the piston rod 15 can move forward and backward along the axis direction, thereby driving the driving hinge 8 hinged with the end of the piston rod 15 to move forward and backward along the axis direction.

[0034] The other components of this embodiment are the same as in Embodiment 1. The movement of the triangular plate 3, the connecting rod 5 and the slider is driven by the hydraulic cylinder 14, the piston rod 15 and the driving hinge 8, so that the slider can move along the vertical direction. Up and down movement.

[0035] The transmission p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com