Swirl stirring device for wastewater biological treatment anaerobic (anoxic) tank

A technology for biological sewage treatment and stirring device, applied in the field of stirring device, can solve the problems of high energy consumption, sludge deposition, etc., and achieve the effects of energy saving, easy operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

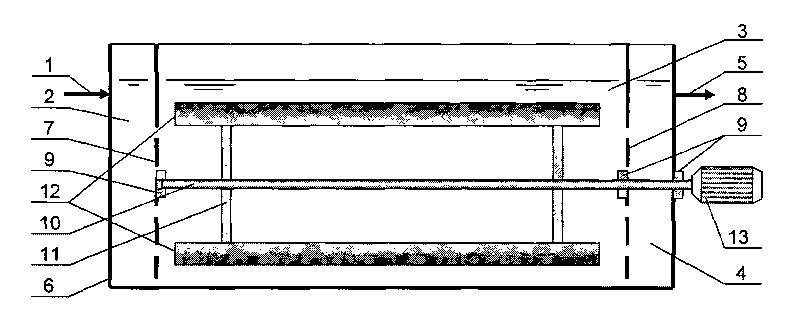

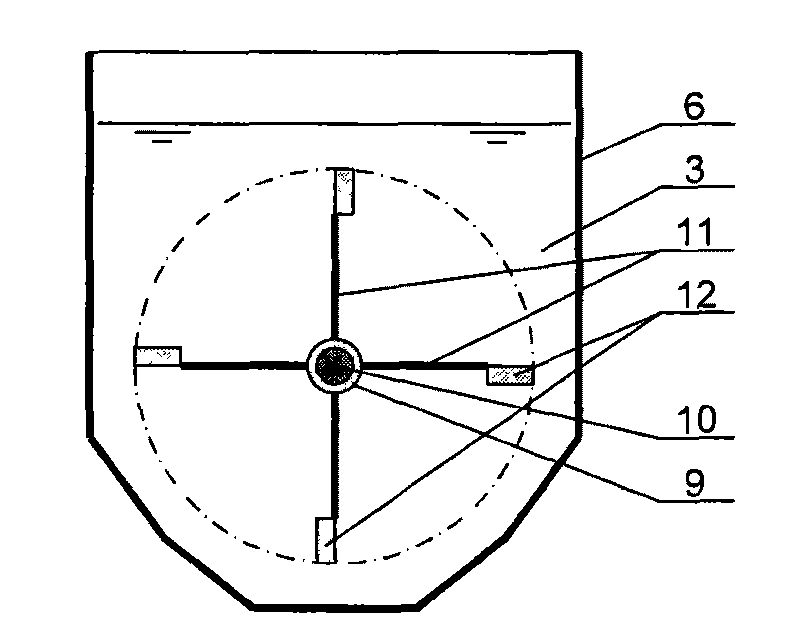

[0020] The treatment process of an urban sewage treatment biological phosphorus removal pilot plant is an anaerobic / aerobic combined process. The anaerobic reaction pool has a water depth of 1.0 meters, a length of 1.4 meters and a width of 0.8 meters. When the horizontal flow rate is 0.01 m / s, a large amount of sediment is formed in the anaerobic tank, and the mixing performance of the sludge is extremely poor, and the corresponding biological reaction cannot be completed. Implement the low-energy swirl stirring device of the present invention in the anaerobic pond, with reference to figure 1 and figure 2 .

[0021] The swirl stirring device is mainly composed of a horizontal shaft 10 , a stirring blade support 11 , a stirring blade 12 and a motor 13 . The horizontal shaft 10 is fixed to the shaft of the motor 13, and the horizontal shaft 10 is fixed with two sets of stirring paddle brackets 11, and each set of stirring paddle brackets 11 is symmetrically equipped with tw...

Embodiment 2

[0025] The treatment process of an urban sewage treatment biological denitrification pilot plant is an anoxic / aerobic combined process. Anoxic pool adopts stirring device of the present invention, with reference to figure 1 and figure 2 . The water depth of the anoxic pool reaction pool is 1.0 meters, the blade width is 0.08 meters, and the outer edge of the blades is 0.3 meters away from the water surface. Other parts of device installation are the same as embodiment 1.

[0026] Incoming water 1 flows into the stirring reaction zone of the anoxic tank evenly at a horizontal flow rate of 0.02 m / s along the horizontal direction of the reaction tank body. When the shaft speed is 8 rpm, the maximum speed of the liquid flow rotating body is 0.3 m / s. Under this condition, there is no sludge sedimentation in the anoxic pool, the mixing is uniform, and the oxidation-reduction potential in the pool can be maintained at -50mV, and a good anoxic effect is obtained.

Embodiment 3

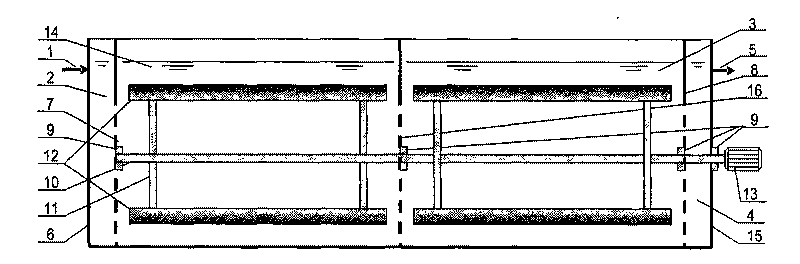

[0028] The treatment process of a pilot plant for biological denitrification and phosphorus removal of urban sewage treatment is an anaerobic / anoxic / aerobic combined process. The anaerobic tank and the anoxic tank are connected in two stages. Single motor coaxial drive, refer to image 3 .

[0029] The water depth of the anaerobic pool and the anoxic pool are both 2.5 meters, and a swirl stirring device is installed respectively, driven by a single motor coaxially. The swirl stirring device is mainly composed of a horizontal shaft 10 , a stirring blade support 11 , a stirring blade 12 and a motor 13 . The horizontal shaft 10 is fixed with the motor 13 shafts. Three groups of stirring paddle supports 11 are fixed on the horizontal shaft 10 of each swirling flow stirring device, and two stirring paddles 12 are symmetrically installed on each group of stirring paddle supports 11; 0.3 meters.

[0030] The anaerobic pool 6 and the anoxic pool 15 are made of steel plates, separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com