Energy-saving stove

A stove and stove technology, which is applied in the field of combustion equipment, can solve the problems of deteriorating chef's working environment, uneven combustion firepower, and rising kitchen temperature, and achieve the effects of improving the working environment, reducing exhaust gas and heat emissions, and reducing the temperature of exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

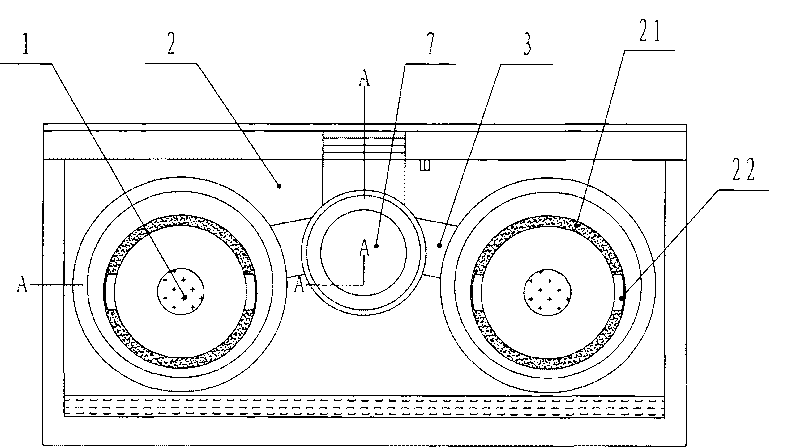

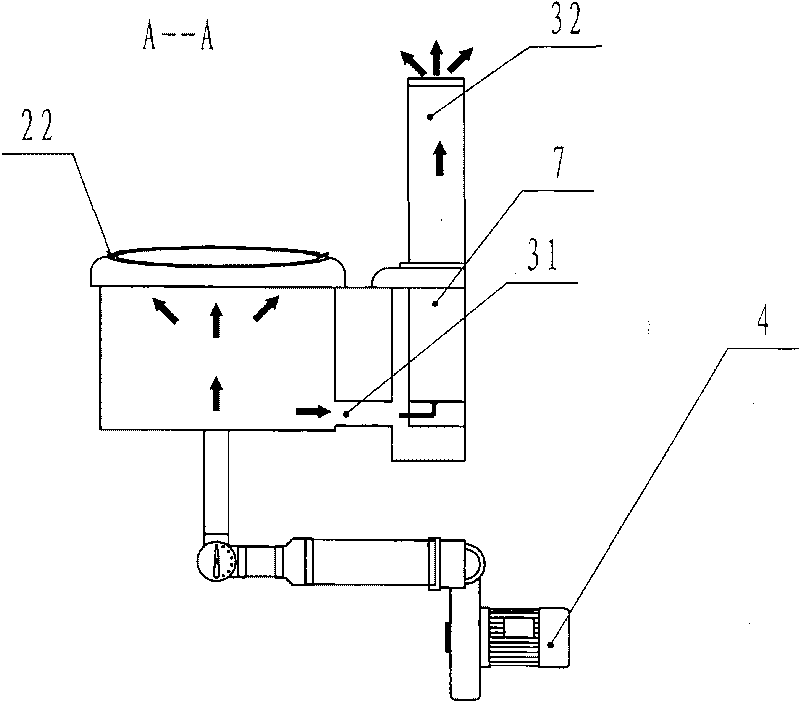

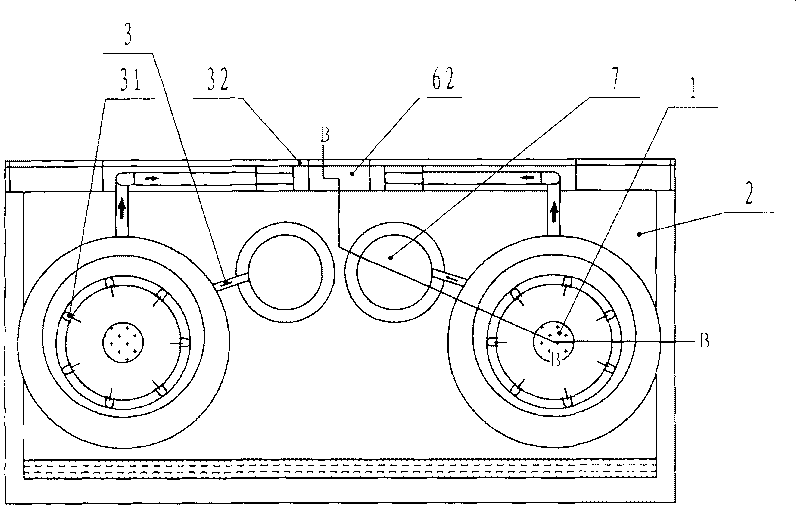

[0017] Example 1, such as image 3 , Figure 4 Shown, a kind of energy-saving cooker, it comprises furnace core 1, kitchen range top 2, exhaust flue 3, air blower 4, soup pot 7, also has an exhaust fan 5 to join with exhaust duct 3, the flue mouth 31 of exhaust duct 3 Located on the upper part of the stove, close to the bottom of the pot seat ring 21, the outside of the exhaust duct 3 is wrapped with the water tank 6, that is, the middle part of the exhaust duct 3 is immersed in the water tank 6, the exhaust duct 3 passes through the water tank 6, and its exhaust port 32 Can connect to outdoor, and water tank 6 communicates with soup pot 7, and the pot seat ring full circle on the kitchen range top 2 is a complete circumference, so that exhaust fan 5 sucks air. A plurality of smoke outlets 31 are evenly arranged on the circumference, and each smoke outlet 31 is connected to a coiled pipe exhaust duct 3, or multiple smoke exhaust outlets 31 are connected to a coiled pipe exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com