Abbe refractometer and light path realization method

A technology of incident surface and outgoing surface, which is applied in the field of Abbe refractometer and optical path realization, can solve the problems that restrict the accuracy of automatic Abbe refractometer, is not conducive to the miniaturization of the instrument, and the cost of the instrument is high, so as to achieve light weight and structure. Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

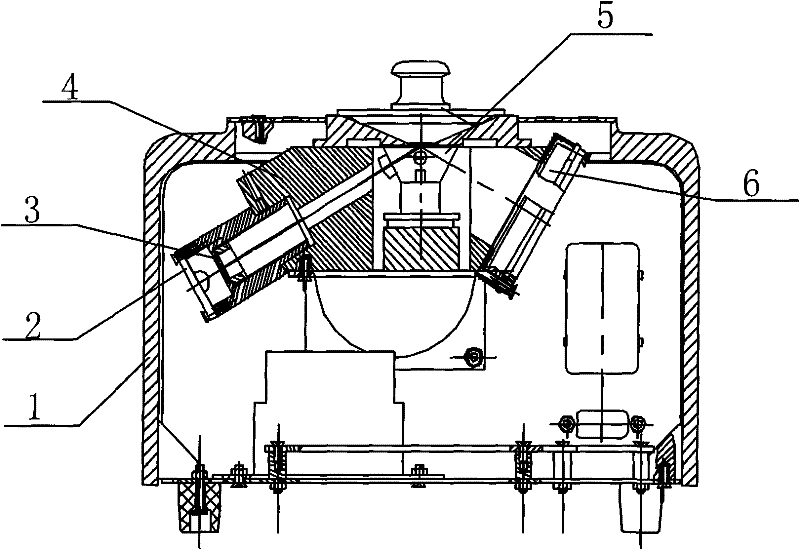

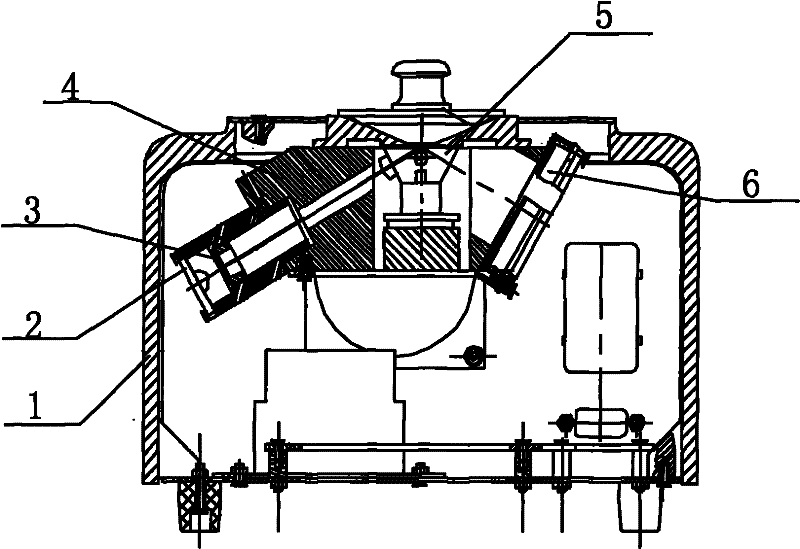

[0034] Such as figure 1 As shown, the optical path structure of the Abbe refractometer provided by the present invention includes an LED light source group 2, a linear array CCD receiving surface 6, and an optical path seat 4, and is characterized in that it also includes a condensing and refracting assembly 5, which has The sample measurement surface, the incident surface and the outgoing surface, the incident surface of the condensing and refracting component is perpendicular to the axis of the circular hole placed inside the optical path seat, and the axis of the circular hole is also perpendicular to the light-emitting surface of the LED light source group, The outgoing surface of the light-condensing component is parallel to the receiving surface of the linear array CCD, the incident surface of the light-condensing component is the inci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Focal length | aaaaa | aaaaa |

| Clear aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com