Bearing vibration checking instrument

A calibrator and tile vibration technology, applied in the field of measurement, can solve the problems of poor standardization, small vibration frequency adjustment range, lack of intelligent data analysis and communication functions, etc., to achieve convenient output, improve calibration work efficiency, and friendly man-machine interface degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

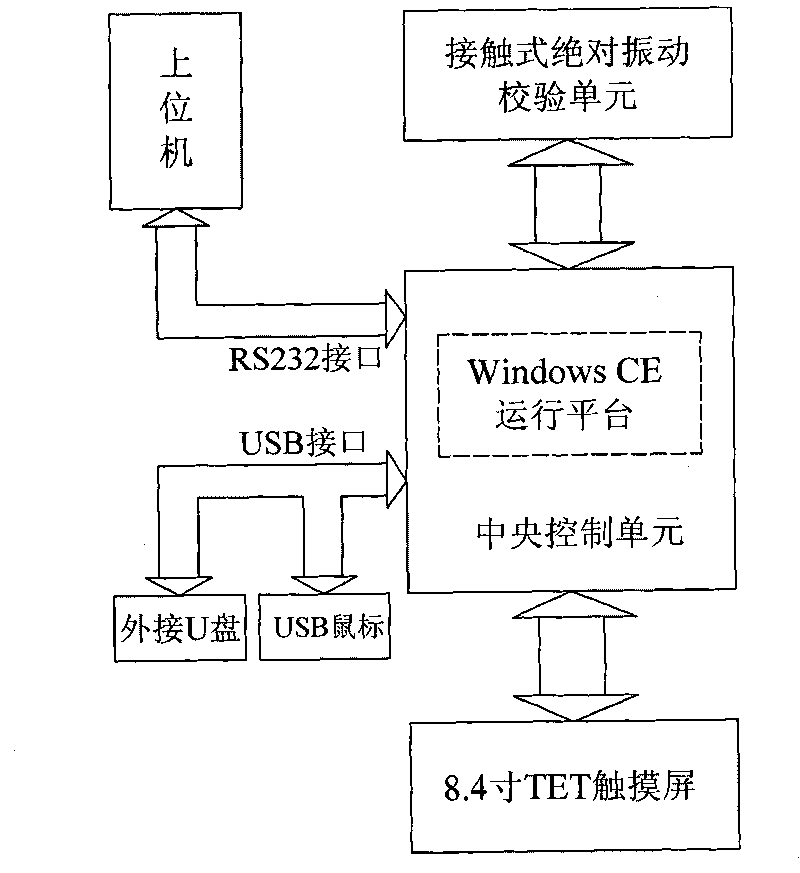

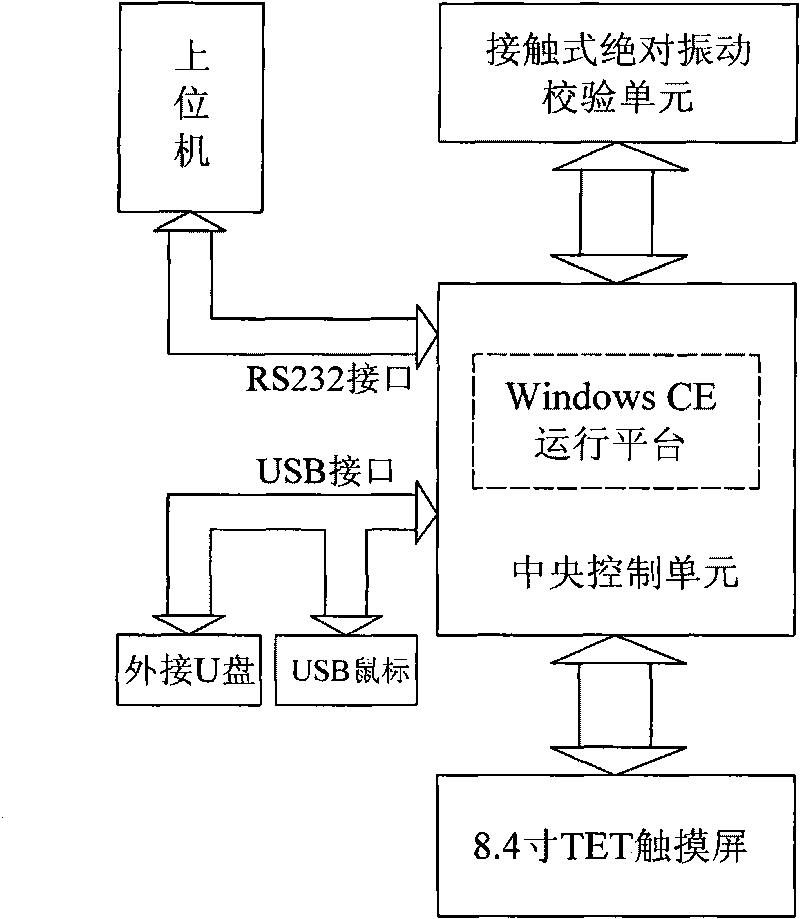

[0027] figure 1 Among them, the present invention at least includes a contact type absolute vibration calibration unit and a central control unit, and its key improvement points are that a Windows CE operating platform is set in the central control unit; measurement software is set in the Windows CE operating platform; the measurement software and the contact type Absolute vibration calibration unit integration; the measurement software controls the operation or measurement action sequence of the contact type absolute vibration calibration unit, reads the measurement results, calculates, displays and stores the measurement parameters, and automatically draws the real-time waveform of the sensor under test, the sensor under test Linear curve, spectral curve, sensitivity error curve.

[0028] Its central control unit is equipped with an 8.4-inch TET touch screen as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com