Anti-dazzle film, anti-dazzle polarizer and image display apparatus

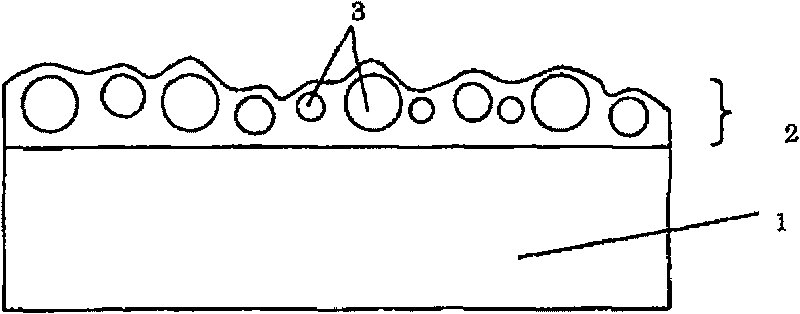

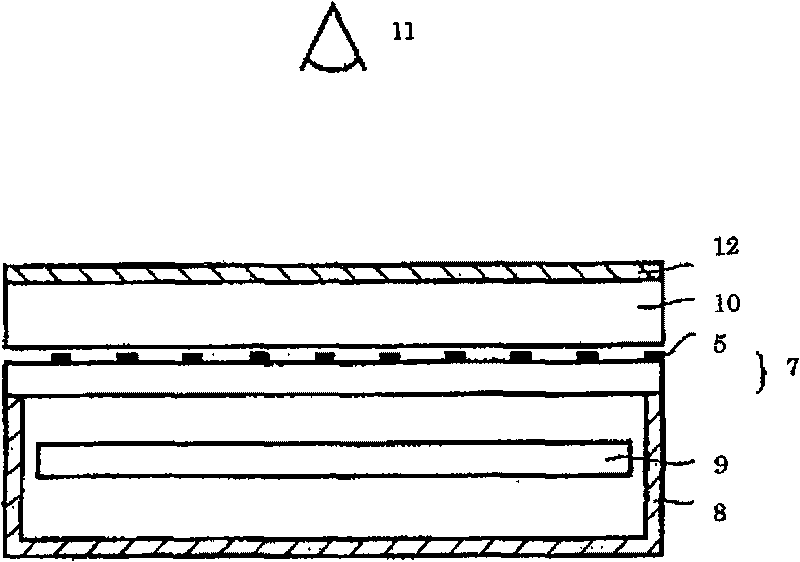

An anti-glare polarizer and anti-glare film technology, which is applied in polarizing elements, nonlinear optics, electronic equipment, etc. The effect of lowering, excellent visibility and durability, and high anti-glare performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

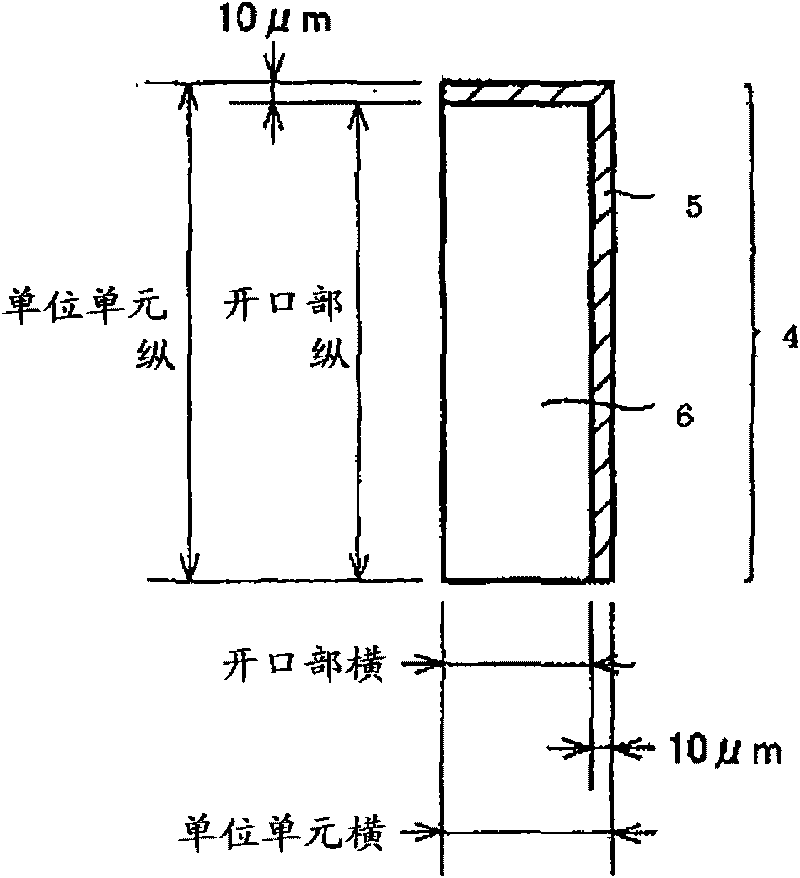

Method used

Image

Examples

Embodiment 1

[0072] (Preparation of Coating Solution A)

[0073] Each of the following components was dissolved in ethyl acetate at a solid content concentration of 60%, to prepare an ultraviolet curable resin composition A having a refractive index of 1.53 after curing.

[0074] Pentaerythritol triacrylate 60 parts

[0075] Polyfunctional urethane acrylate (reaction product of hexamethylene diisocyanate and pentaerythritol triacrylate) 40 parts

[0076] Next, with respect to 100 parts by weight of the solid content of the ultraviolet curable resin composition A, methyl methacrylate / styrene copolymer resin beads (weight-average particle diameter 7.43 μm, refractive index 1.55, dipped at 23° C. Volume change rate in ethyl acetate for 48 hours: 11%) 40 parts by weight, "Lucirin TPO" (manufactured by BASF Corporation) as a photopolymerization initiator 5 parts by weight, dilute with ethyl acetate so that the solid content rate is 60 %, thereby preparing a coating liquid A.

[0077] (Produc...

Embodiment 2

[0082] With respect to 100 parts by weight of the solid content of the above-mentioned ultraviolet curable resin composition A, add methyl methacrylate / styrene copolymer resin beads (weight-average particle diameter: 7.74 μm, refractive index: 1.55, immersed in 40 parts by weight of "Lucirin TPO" (manufactured by BASF Corporation) as a photopolymerization initiator, diluted with ethyl acetate to make the solid content rate 60 %, to prepare coating solution B.

[0083] Except having used this coating liquid B, it carried out similarly to Example 1, and obtained the antiglare film B which consists of the laminated body of the hard-coat layer which has uneven|corrugated surface, and a TAC film.

Embodiment 3

[0085]With respect to 100 parts by weight of the solid content of the above-mentioned ultraviolet curable resin composition A, methyl methacrylate / styrene copolymer resin beads (weight average particle diameter 7.63 μm, refractive index 1.55, immersed in 40 parts by weight of "Lucirin TPO" (manufactured by BASF Corporation) as a photopolymerization initiator, diluted with ethyl acetate to make the solid content rate 60% %, to prepare coating solution C.

[0086] Except having used this coating liquid C, it carried out similarly to Example 1, and obtained the anti-glare film C which consists of the laminated body of the hard-coat layer which has uneven|corrugated surface, and a TAC film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com