Anti-dazzle film and anti-dazzle polarizing plate

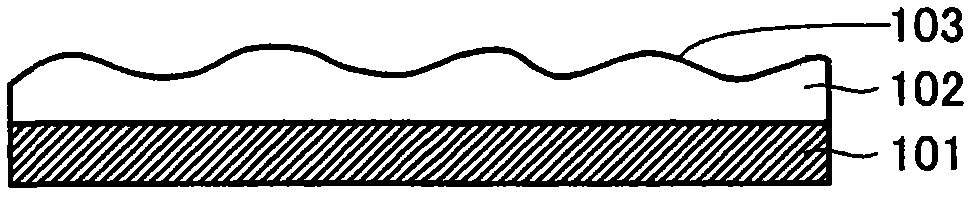

An anti-glare film and anti-glare layer technology, applied in polarizing elements, nonlinear optics, coatings, etc., can solve problems such as damage to visibility, and achieve the effects of deterioration suppression, excellent anti-glare, and good contrast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

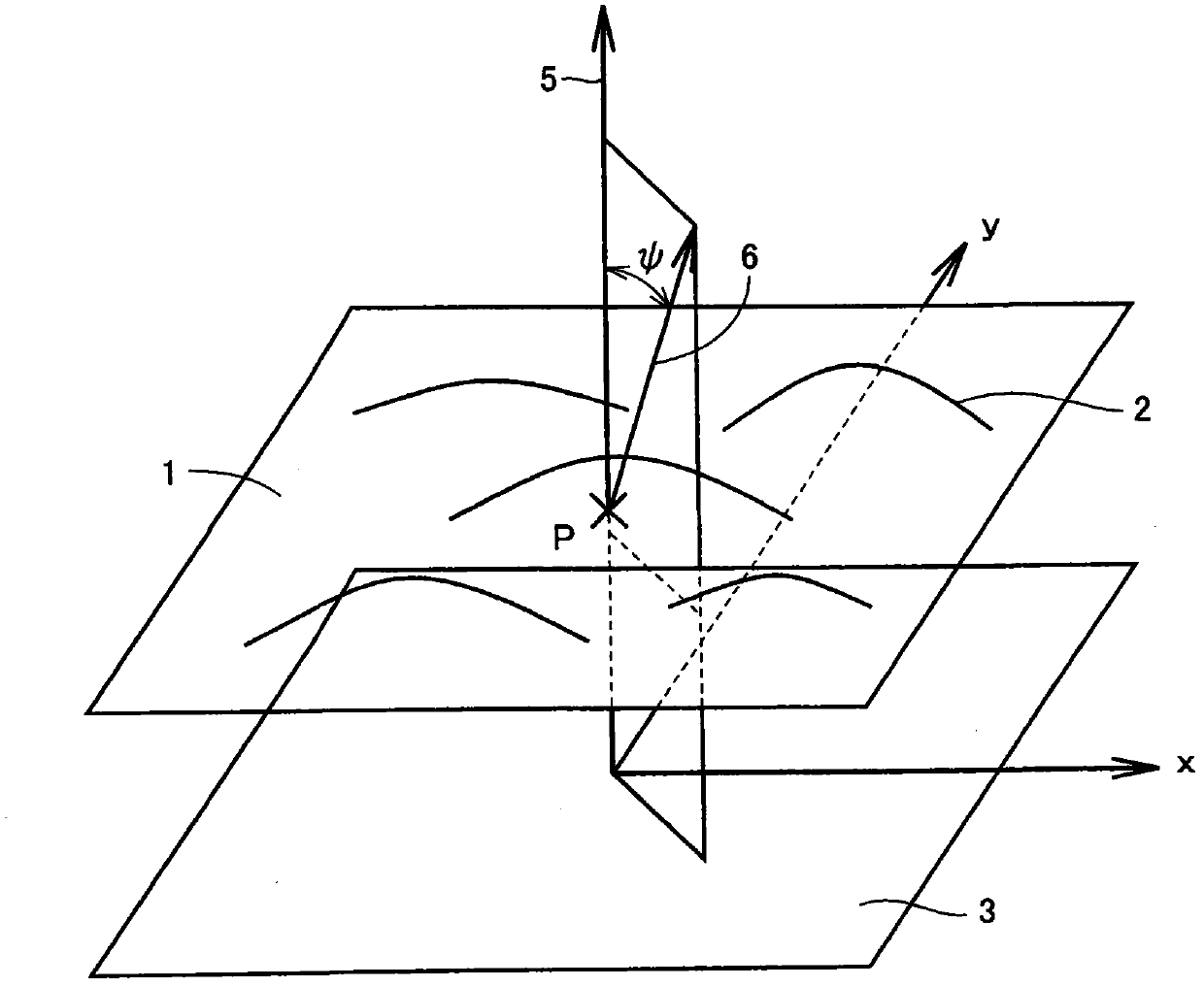

[0183] (Preparation of molds for anti-glare film production)

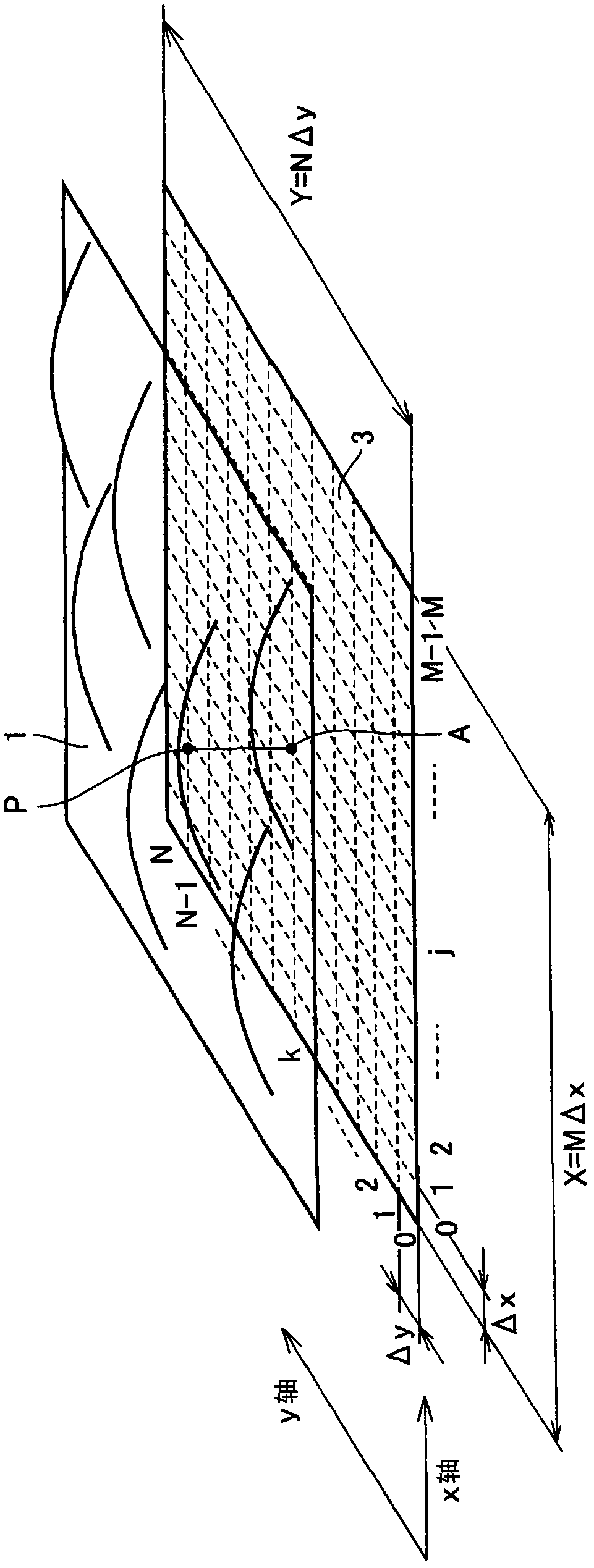

[0184] An aluminum roll (A5056 based on JIS) having a diameter of 200 mm was prepared on the surface of which copper ballard plating was performed. The copper ballard plating consists of copper plating / thin silver plating / surface copper plating, and the overall thickness of the plating is set to about 200 μm. The copper-plated surface is mirror-polished, and a photosensitive resin is applied to the polished copper-plated surface, followed by drying to form a photosensitive resin film. Next, use the laser to align the Figure 15 A pattern composed of image data shown in , is exposed on a photosensitive resin film and developed. Exposure and development by laser were performed using "Laser Stream FX" (manufactured by Think Laboratory Co., Ltd.). A positive photosensitive resin is used for the photosensitive resin film. Figure 15 The pattern shown in is a pattern in which a plurality of dots with a diameter of 12...

Embodiment 2

[0191] In the exposure process of mold making, laser exposure is performed on the photosensitive resin film to Figure 16 The pattern formed by the image data shown in is a pattern formed by repeating and juxtaposing a plurality of patterns in succession. The etching amount in the first etching process is set to 5 μm, and the etching amount in the second etching process is set to 12 μm. , Mold B was produced in the same manner as in Example 1. Except having used the mold B obtained, it carried out similarly to Example 1, and produced the antiglare film B. Figure 16 The pattern shown in is a pattern obtained by randomly arranging a plurality of dots with a dot diameter of 12 μm and applying a spatial frequency of 0.035 μm -1 The following low spatial frequency components and 0.135μm -1 The above-mentioned high-spatial-frequency components are removed by a band-pass filter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com