Embedded digital control system for carton packing complete equipment

A technology of digital control system and complete set of equipment, applied in the direction of packaging, transportation and packaging, comprehensive factory control, etc., can solve the problem of low modularization and intelligence, low portability and reconfigurability, and control device action area Minor problems, to achieve the effect of improving reliability and real-time performance, shortening the secondary development cycle, and increasing openness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

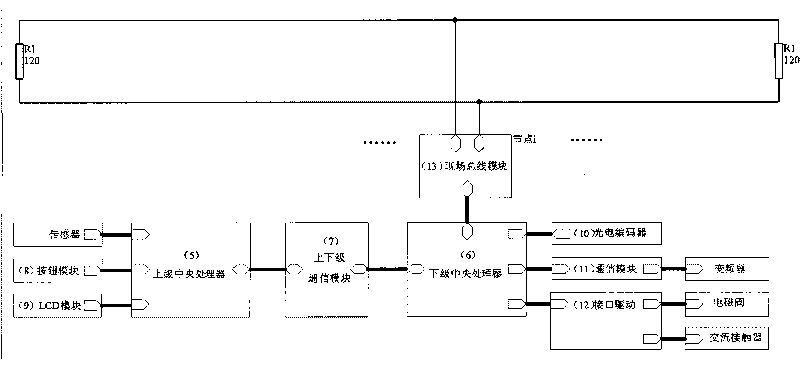

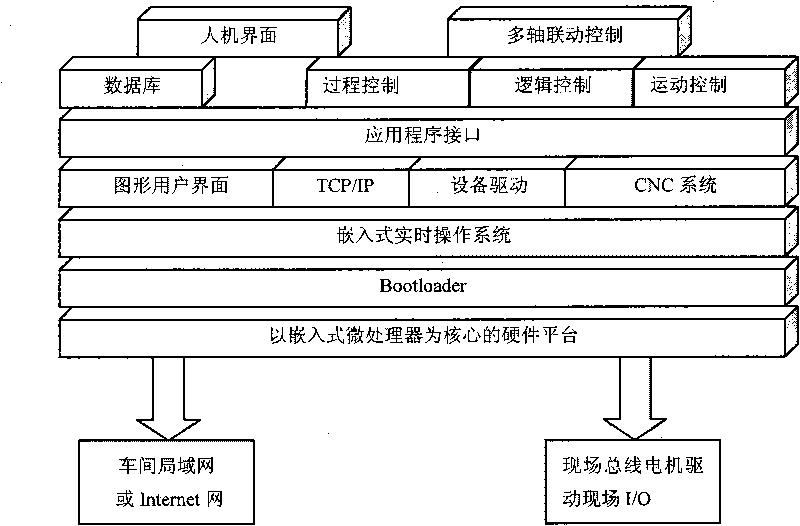

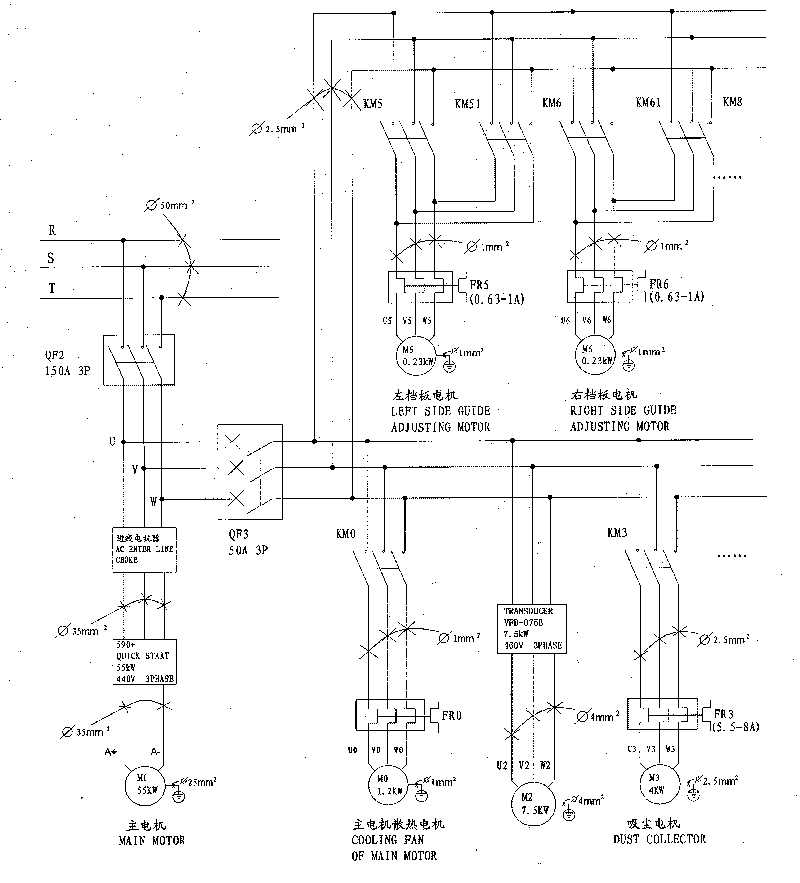

[0034] The schematic diagram of the module structure of the present invention is as figure 1 As shown, it includes the controller of the paper feeding part (1), the controller of the printing part (2), the controller of the slotting part (3), and the controller of the die cutting part (4); the core controllers of each part are respectively processed by the superior central device (5) and lower-level central processing unit (6), connected by respective upper-level communication modules (7); the input interface of the upper-level central processing unit (5) of each department and sensor, button module (8), LCD module ( 9) connection; the lower-level central processing unit (6) of each department is connected with the photoelectric encoder input module (10), the frequency converter communication module (11), the interface driver module (12) and the field bus module (13) respectively, and the lower-level central processing unit (6) of each department The central processing unit (6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com