Permanent magnet generator rotor

A technology for permanent magnet generators and rotors, which is applied in the directions of magnetic circuit rotating parts, manufacturing stator/rotor body, magnetic circuit shape/style/structure, etc., which can solve the problems of reducing output power, sweeping chamber, and uneven magnetic density in the air gap and other issues to achieve the effect of weight reduction, uniform air gap and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing.

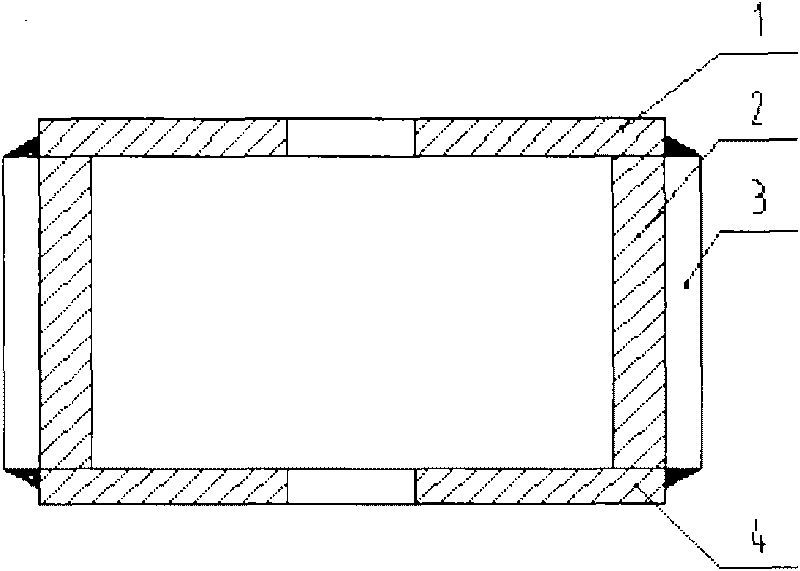

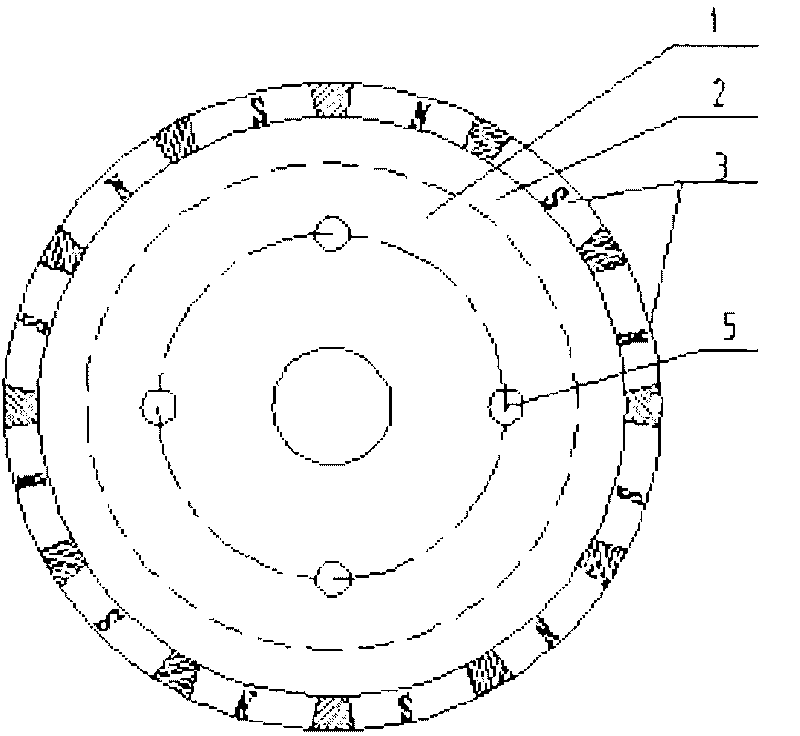

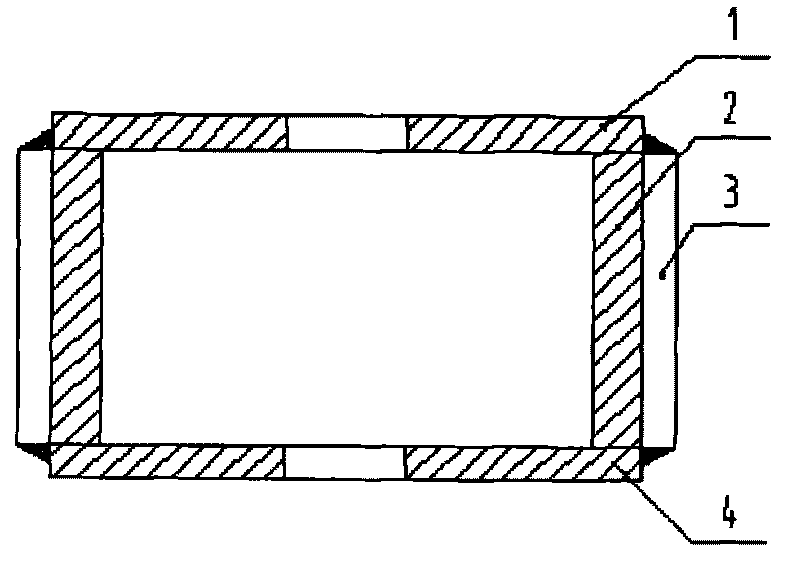

[0009] In the figure: 1. Upper pressing plate 2. Iron core 3. Permanent magnetic steel 4. Lower pressing plate 5. Bolts

[0010] As shown in the figure, the rotor of the permanent magnet generator of the present invention includes a rotating shaft, an iron core 2 and a permanent magnet steel 3. The iron core 2 is punched and laminated from circular silicon steel sheets, and the upper pressing plate 1 and the lower pressing plate 4 pass through 4 5 through-bolts are tightened, and the middle of the pressure plate is welded and fixed with the shaft. The outer circumference of the iron core 2 is evenly fixed with 16 permanent magnets 3 with alternating polarities. The shape of the permanent magnets 3 is a combination of trapezoid and rectangle. After positioning, epoxy resin is used to seal along the periphery of the permanent magnet steel 3 to form a cylindrical permanent mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com