Resonance oscillation converter for improving synchronous rectification control

A resonant converter, synchronous controller technology, applied in output power conversion devices, control/regulation systems, high-efficiency power electronic conversion, etc., can solve the requirements of synchronous rectifier parasitic inductance, limited maximum operating frequency of 500kHz, low efficiency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

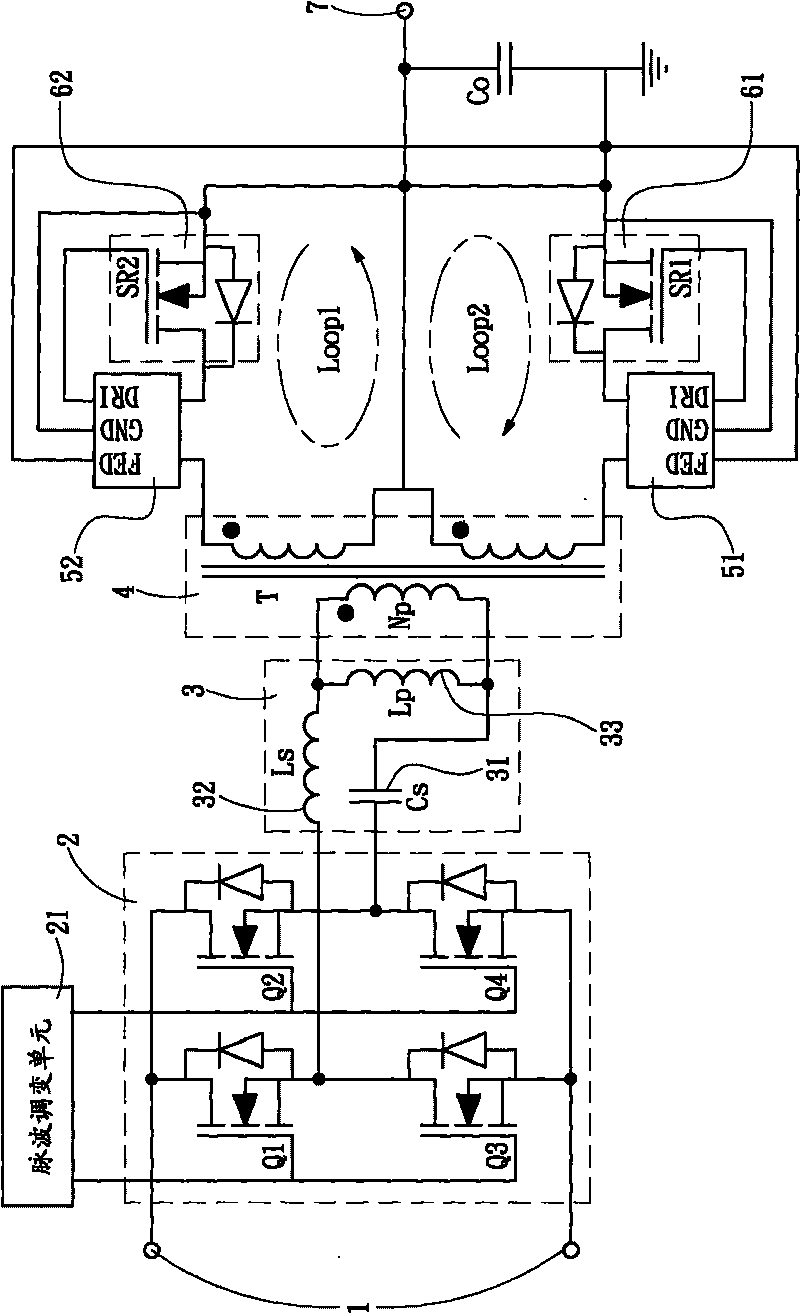

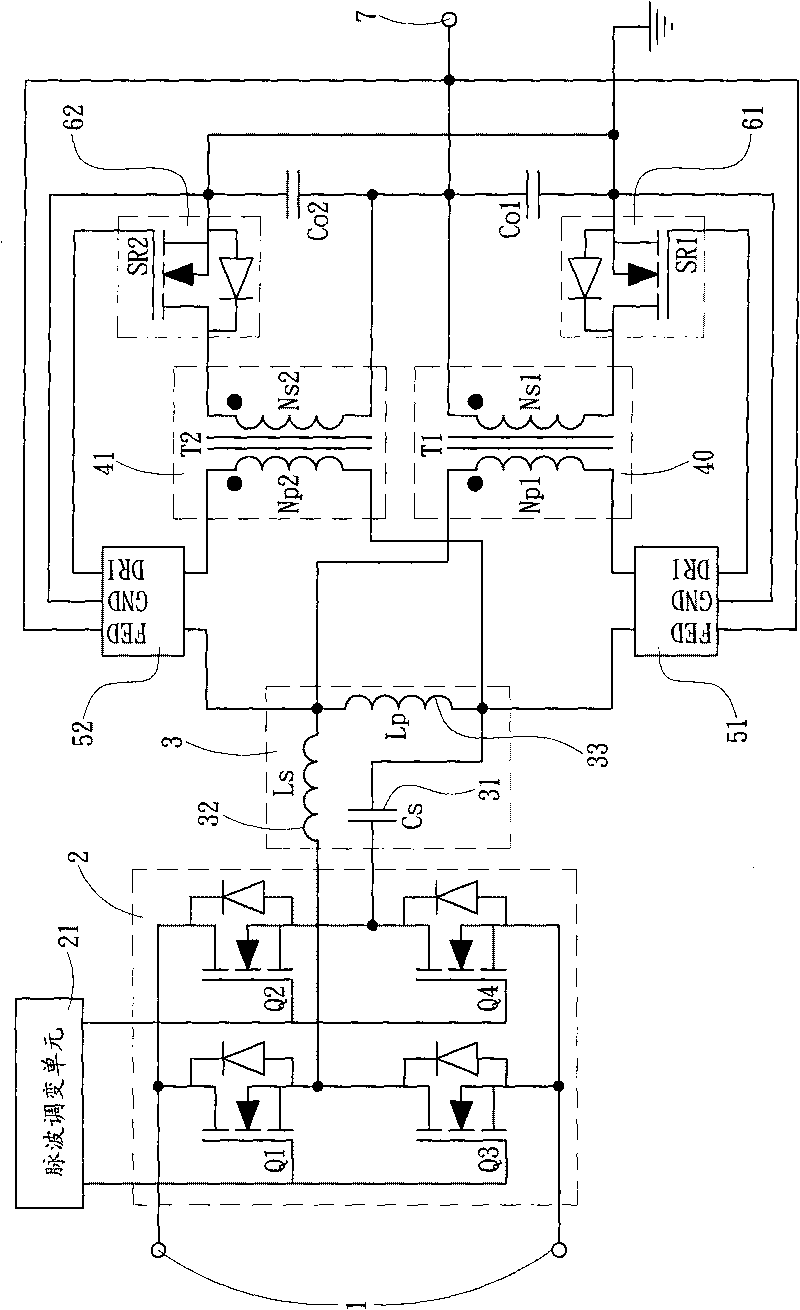

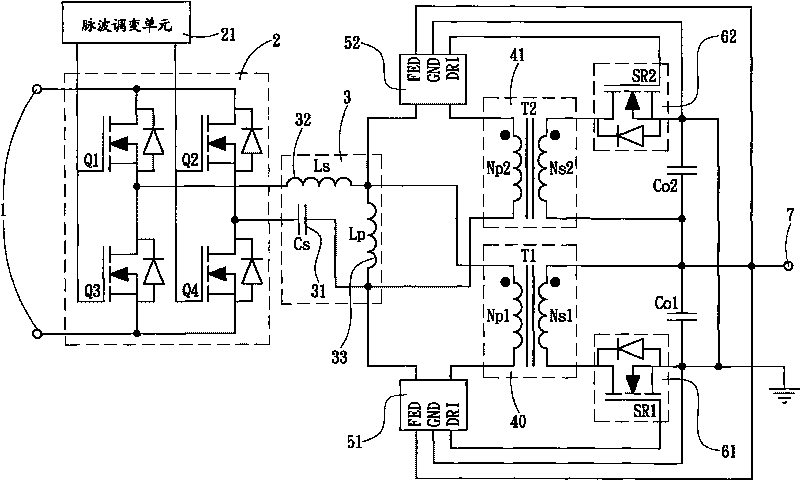

[0012] The present invention is a resonant converter with improved synchronous rectification control, and its circuit structure can be found in figure 2 , the resonant converter is connected to a power source 1 to obtain an input power, and the input power is direct current, and a pulse modulation unit 21 generates a driving pulse to control the on and off of a switching unit 2, thereby modulating The cycle and current flow direction of the input power sent to a resonant circuit 3, the resonant circuit 3 is composed of a resonant capacitor 31, a first resonant inductor 32 and a second resonant inductor 33 connected in series; in addition, the resonant circuit 3 The resonant converter is provided with two transformers 40, 41 electrically connected to the resonant circuit 3, and the primary side of the two transformers 40, 41 obtains the input power modulated by the resonant circuit 3, wherein the two transformers 40, 41 41 The side with the same polarity of the primary side wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com