Bamboo glue board manufacturing process and production line

A production process and technology of bamboo plywood, applied in the direction of plywood press, veneer press, manufacturing tools, etc., can solve the problems of wasting water resources, increasing costs, wasting heat energy, etc., to save labor costs and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

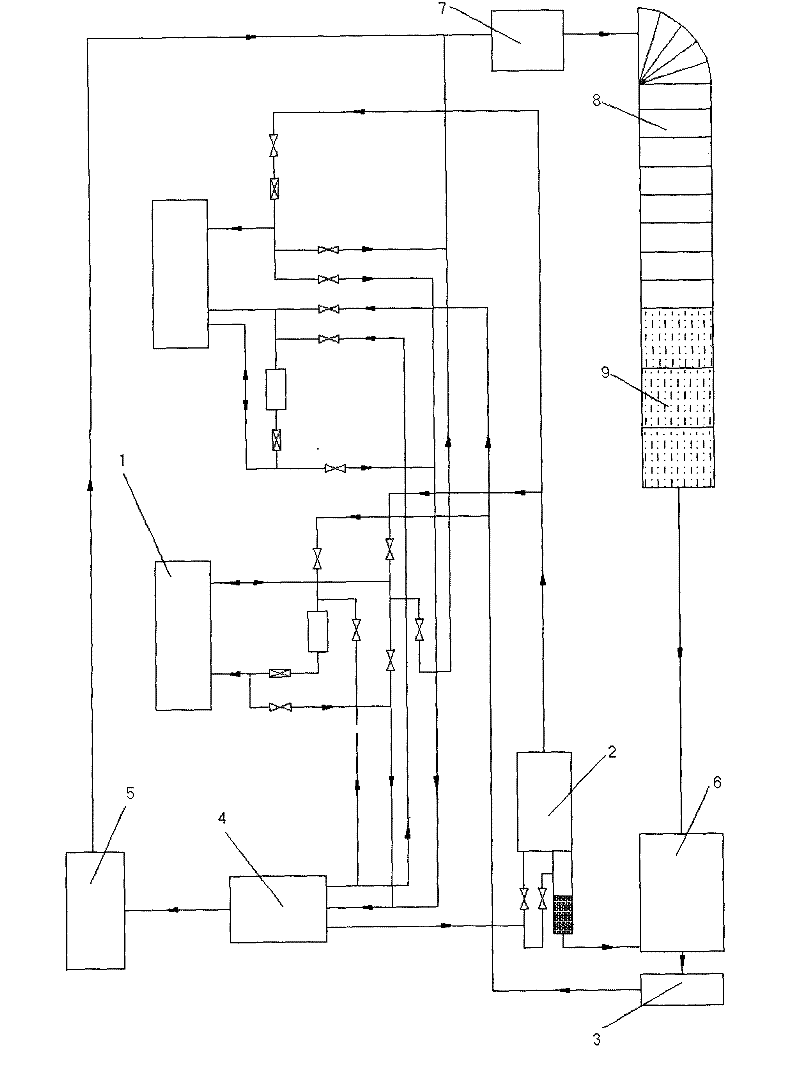

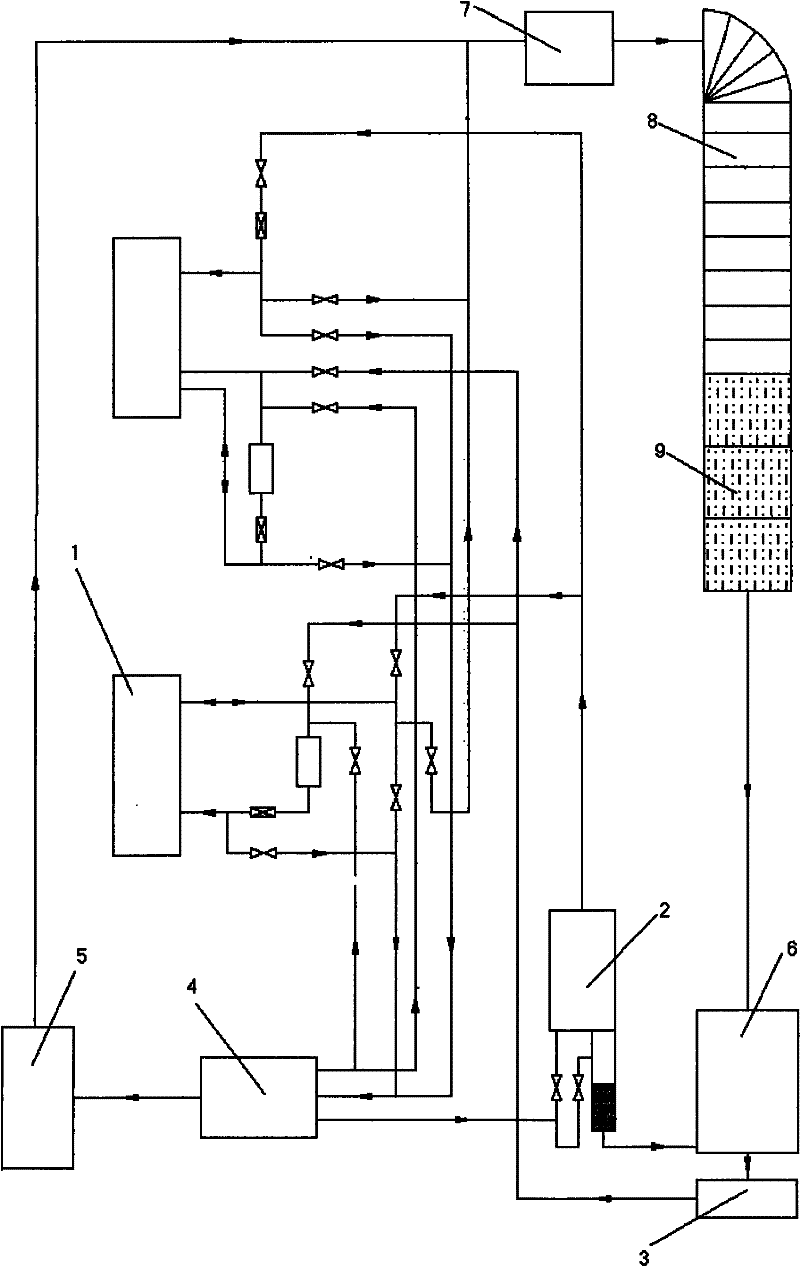

[0015] See the accompanying drawings: bamboo plywood production line, including a sedimentation cooling pool 9, in the sedimentation cooling pool 9 there are steps from top to bottom along the water flow direction, and the outlet water of the sedimentation cooling pool 9 is connected to the cold water through pipelines Reservoir 6, the cold water reservoir 6 is connected to the cold water high level tank 3 through a pipeline, and the bottom of the cold water high level tank 3 is connected to the hot press 1 through a pipeline to supply production water for it; the water outlet of the medium temperature pool is through The pipeline is connected to the water inlet of the precipitation cooling tank 9; a boiler 2 is provided, and the hot water outlet of the boiler 2 is connected to the cold water storage tank 6 through the filtering precipitation cooling tank 9; a boiling water high level tank 4 is also provided, and the boiling water high level The lower end of the tank 4 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com