Speed control method for free falling winch and method for implementing method

A speed control device and speed control technology, applied in the direction of the hoisting device, etc., can solve the problems of difficult speed control of the hoisting machine, reduced working reliability of the hoisting and hoisting system, large impact, etc., and achieves simple structure, smooth braking, and reduced wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0029] Another embodiment of the present invention: the hydraulic pump can be a one-way pump, and a clutch is added between the transmission shaft of the hydraulic pump and the pinion output shaft. When the reel is lifted, the pinion is disconnected from the hydraulic pump, and when the reel falls freely, the pinion is connected to the hydraulic pump. At this time, the flow control valve can be a throttle valve.

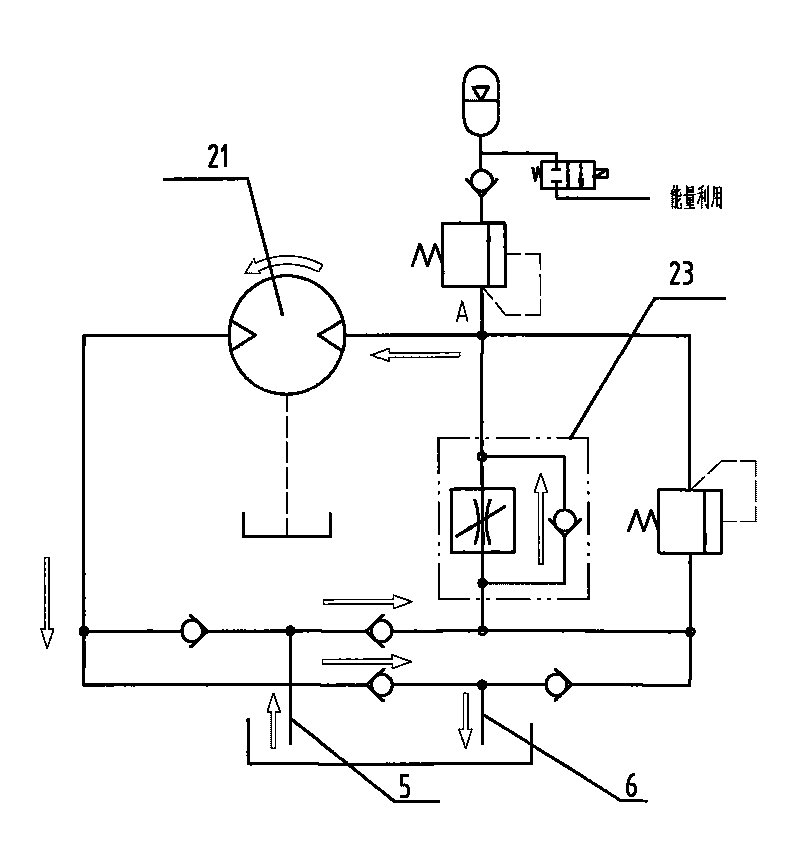

[0030] In the hydraulic circuit using a two-way hydraulic pump, when the winch is lifted, the reel drives the large gear to rotate, the large gear drives the small gear to rotate, and the small gear drives the two-way hydraulic pump to rotate counterclockwise, as image 3 As shown, the oil enters the pipeline through the oil suction pipe 5, pushes open the one-way valve B52 and the one-way valve of the flow control valve 23, enters the two-way hydraulic pump through the inlet and outlet B, and is discharged through the inlet and outlet A, and pushes the one-way valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com