Filling valve and process for filling materials using same

A filling valve and filling technology, applied in packaging, bottling machines, bottle filling, etc., can solve the problems of large filling volume error, long-term adjustment, poor self-cleaning ability, etc., to improve accuracy and ensure accuracy Sexuality and the effect of improving filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

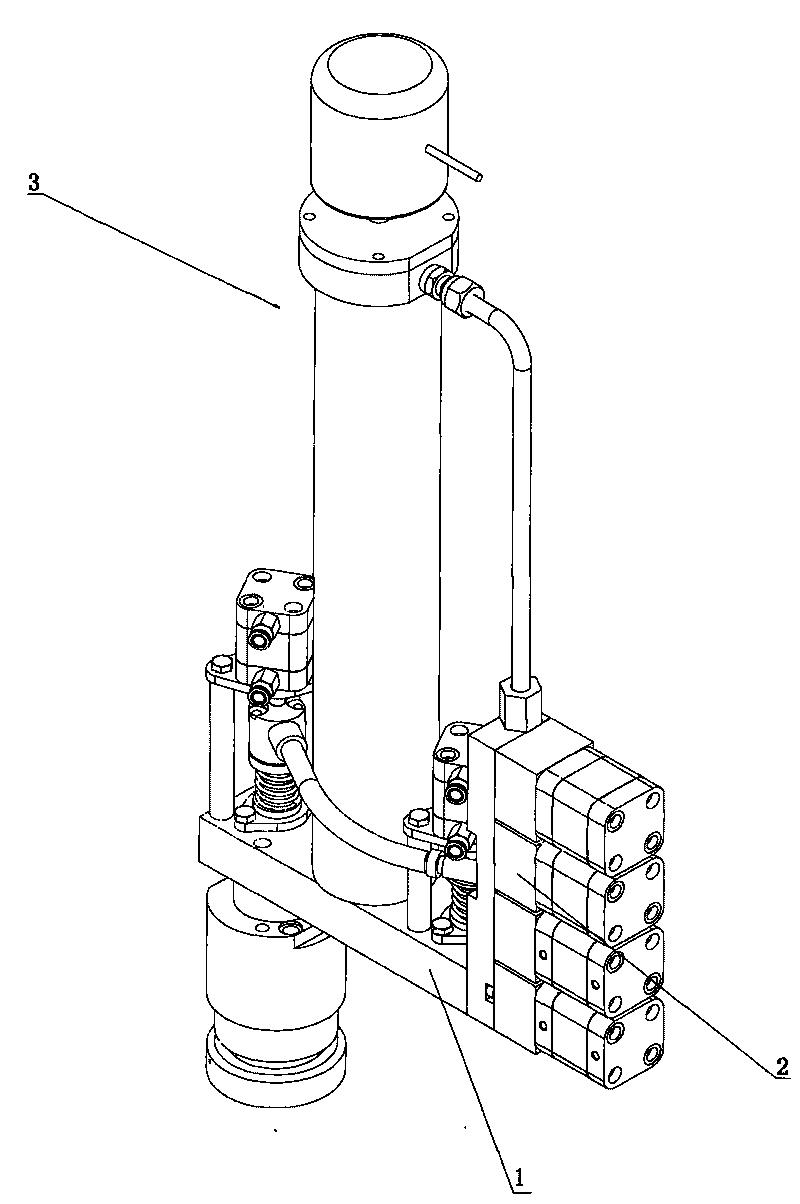

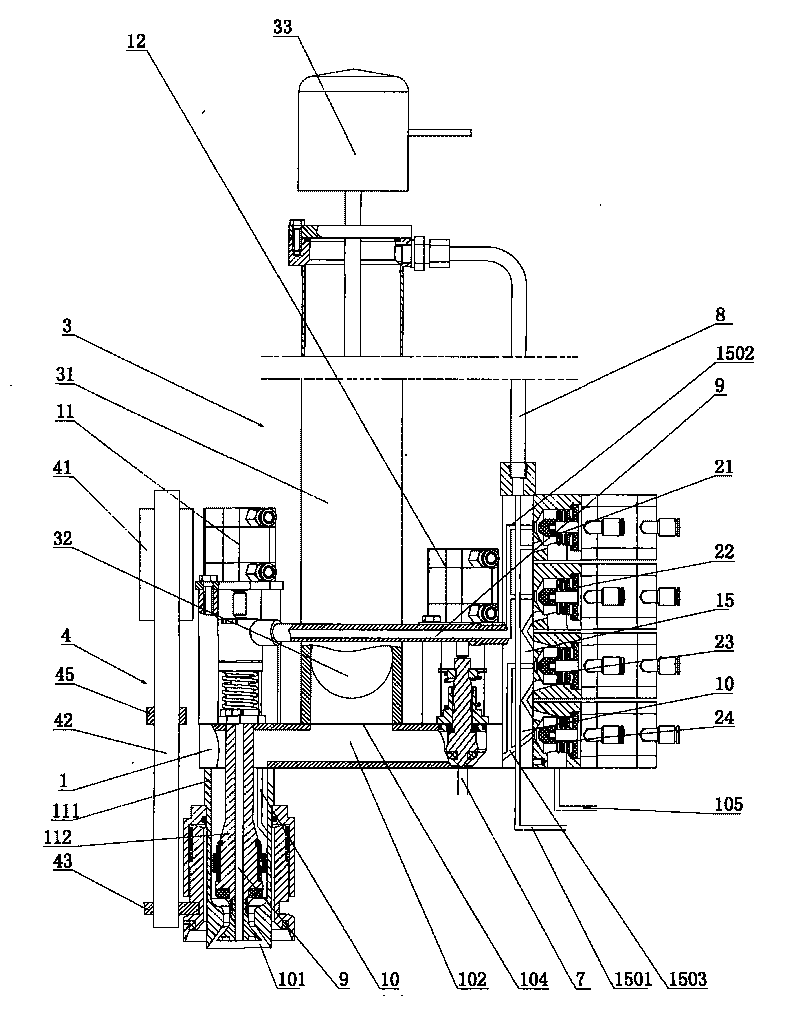

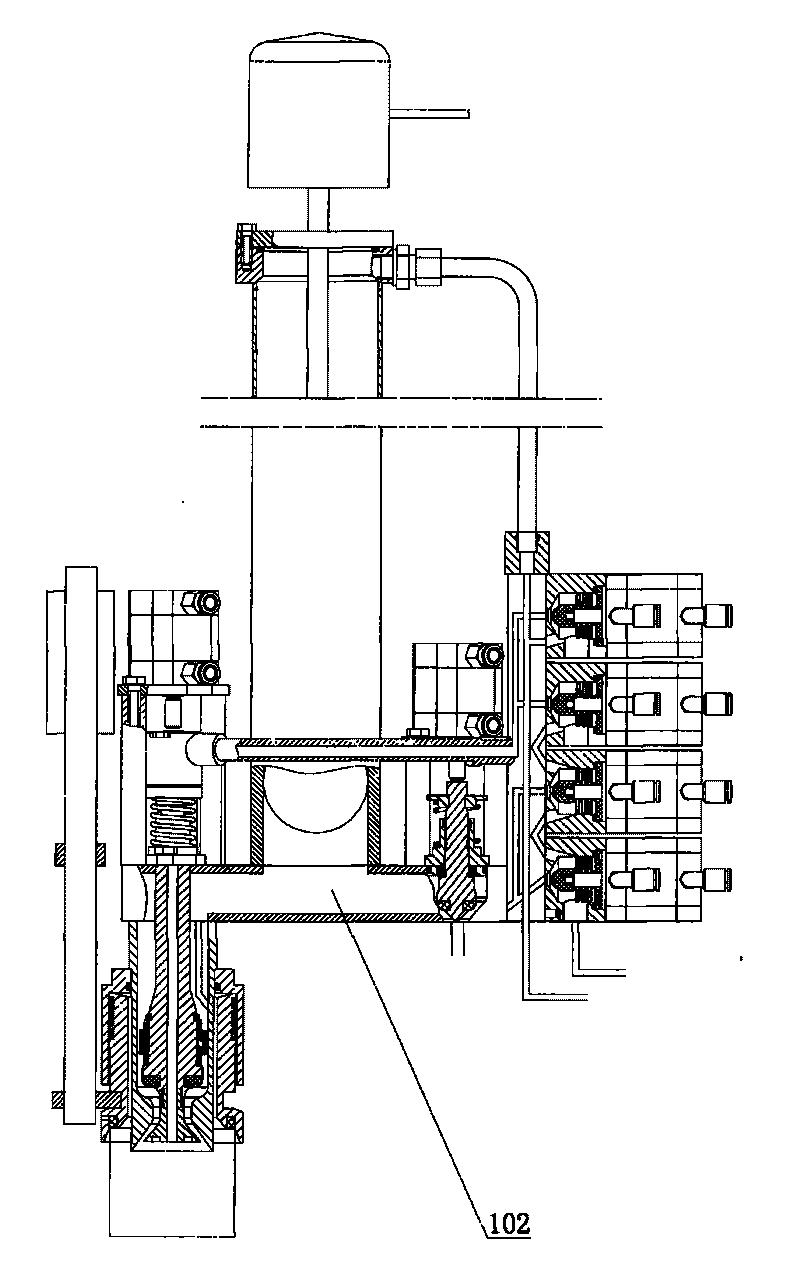

[0049] Such as figure 1 and figure 2 The shown filling valve includes a valve plate 1, on which there is a valve port 101 of the filling valve, and a gasket (not shown) is provided at the valve port 101 of the filling valve; There is a diaphragm valve valve group 2, and the diaphragm valve valve group 2 is provided with 4 diaphragm valves and a gas-collecting channel plate 15. The 4 diaphragm valves are the first diaphragm valve 21, the second diaphragm valve 22. The third diaphragm valve 23 and the fourth diaphragm valve 24, the diameter of the air return hole of the first diaphragm valve 21 is larger than the diameter of the return air hole of the second diaphragm valve 22; There is a back pressure channel 1501, a return air channel 1502 and an exhaust channel 1503; a meter 3 is provided in the middle of the valve plate 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com