Preparation method of high-temperature resisting and salt-resisting filtrate reducer for drilling fluid

A technology of fluid loss reducer and drilling fluid, applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor fluid loss reduction effect, not very obvious effect, and low API fluid loss, etc. Simple, excellent filtration performance, easy to mass-produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

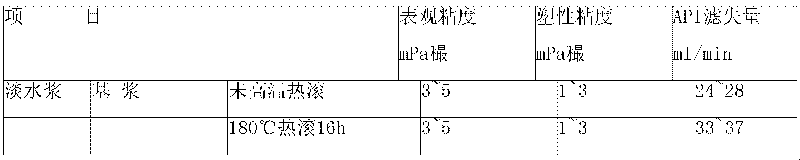

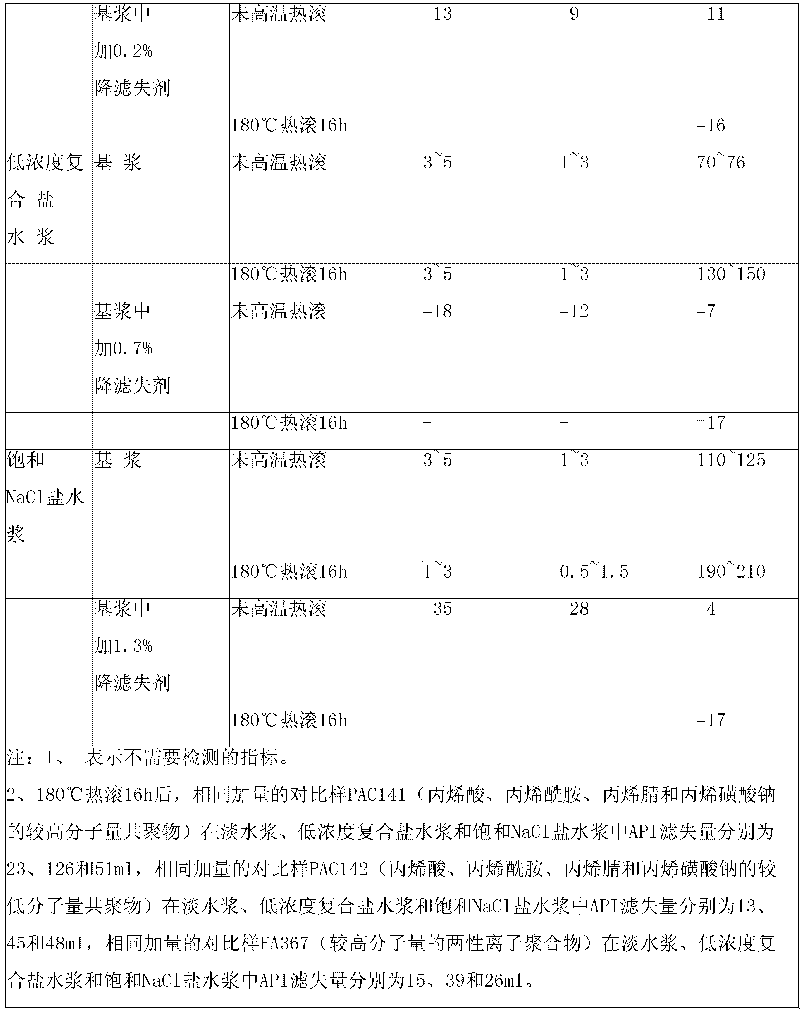

[0027] Preparation method of fluid loss reducer: Dissolve 6.4 kg of sodium hydroxide in 80 liters of deionized water, and simultaneously inject 10.5 liters of acrylic acid into the reactor and stir to mix evenly. Add 21 kg of acrylamide, 3.5 kg of 2-acrylamide-2-methylpropanesulfonic acid, 1.8 kg of urea, 0.5 kg of aluminum citrate, and 0.012 kg of potassium persulfate and mix again. Afterwards, the whole system (pH value about 6.5) was kept at 70°C for 3 hours to obtain the vinyl fluid loss control agent for high temperature and salt drilling fluid. The fluid loss control agent prepared by the above method was mainly determined by the reduction rate of API fluid loss. index, the result is shown in the list.

[0028] main

Embodiment 2

[0030] Preparation method of fluid loss reducer: Dissolve 6.4 kg of potassium hydroxide in 300 liters of deionized water, and simultaneously inject 11.8 liters of acrylic acid into the reactor and stir to mix evenly. Then add 23.2 kg of acrylamide, 1.8 kg of urea, 0.8 kg of aluminum citrate, and 0.015 kg of ammonium persulfate and mix again. Afterwards, the whole system (pH value about 6.0) was kept at 60°C for 3 hours to obtain the vinyl-based high temperature and salt resistant drilling fluid fluid loss reducer. Taking the fluid loss reducer prepared by the above method, the API fluid loss reduction rate is the main factor. index, the result is shown in the list.

[0031] main

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com