Method for recycling polyester waste silks

A technology of waste silk and polyester, which is applied in the direction of single-component polyester rayon, rayon recycling, and adding pigments to spinning liquid, which can solve the problems of poor production stability, inconsistent feeding speed, and product quality. Large problems, etc., achieve high stability and consistent feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

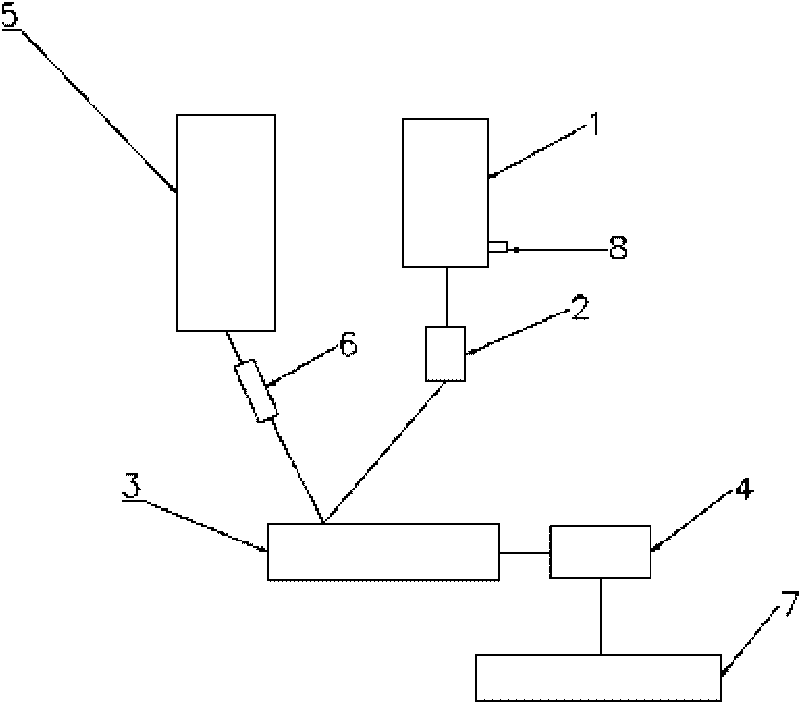

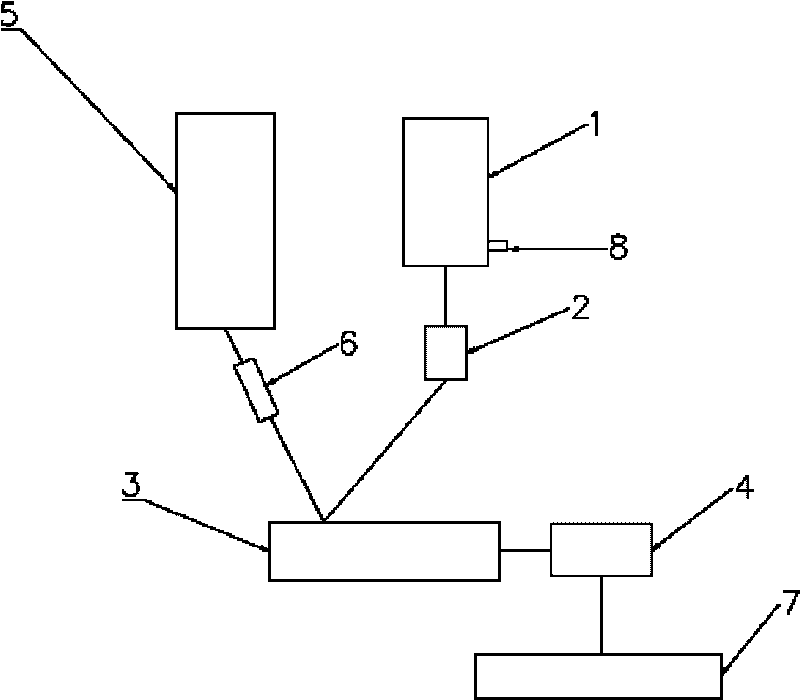

Embodiment 1

[0011] The method for recycling polyester waste silk described in this embodiment first recycles the waste silk produced in the polyester production process, puts it in a dry and clean recycling box after recycling, and packs it regularly and in time. During the recycling process, the recovered waste silk is first cleaned to remove oil and impurities, then dried to remove the water in the waste silk, and then the waste silk is made into small spherical foam materials, and the waste silk made of The foam material is put into the special drying tower 1, and the hot air 8 with a dew point lower than -70°C enters at the bottom of the tower to dry and dehumidify it. The inlet air temperature is between 160-175°C, and the drying time is more than 4 hours. The foam material is measured by the small screw 2 according to 5-50% of the actual production output and then sent to the spinning screw 3. The waste silk foam material measured in proportion is mixed with the original slices of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com