Fiber reinforce plastic (FRP) ribbing folded plate-concrete combined bridge deck

A technology of concrete and composite bridges, which is applied in bridge engineering, fiber reinforced plastics in bridges, and concrete combined applications, can solve problems such as low stiffness, large initial investment of full FRP bridge decks, and difficulty in connecting main girders, and achieve improved Bending stiffness and strength, increased stiffness and strength, and the effect of avoiding erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

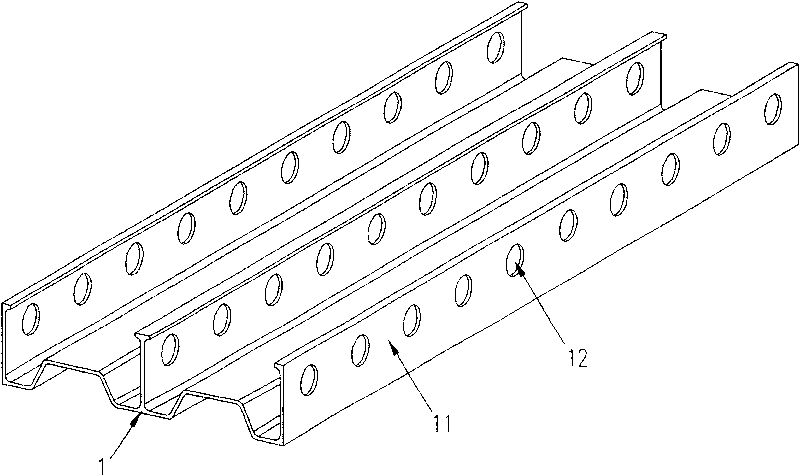

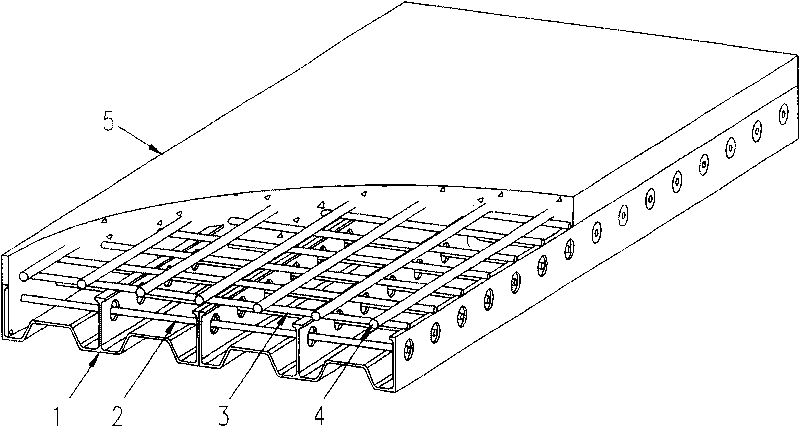

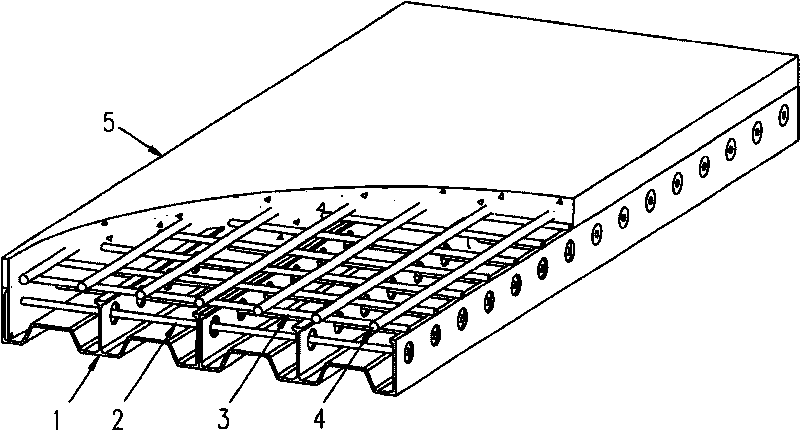

[0025] Such as Figure 1-Figure 2 As shown, the FRP ribbed folded plate-concrete composite bridge deck of the present invention mainly includes an FRP folded base plate 1 with ribs, and a single FRP folded base plate 1 can form a large FRP folded base plate through bolts or adhesives. T-shaped bottom plate, the rib plate 11 of the FRP folded bottom plate 1 is provided with a flange to form a T-shaped rib, and there are evenly arranged round holes 12 on it, and steel bars or FRP bars 2 run through the round holes 12. The top surface is evenly distributed with steel bars or FRP bars 3 in the same direction as the bars penetrating through the round hole 12. At the same time, the main steel bars or FRP bars 4 perpendicular to it are laid on the top surface of the steel bars or FRP bars 3, and then concrete 5 Pouring molding. Among them, the diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com