Reversely bevelled flip bucket

A kind of oblique cutting and reverse technology, which is used in water conservancy projects, embankments, marine engineering and other directions, can solve the problems of oblique cutting and sills that cannot adapt to changes in discharge conditions, endangering the safety of the other side, and impacting river banks, etc., to reduce impact and scour. Destructive effect, weakening effect of scour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

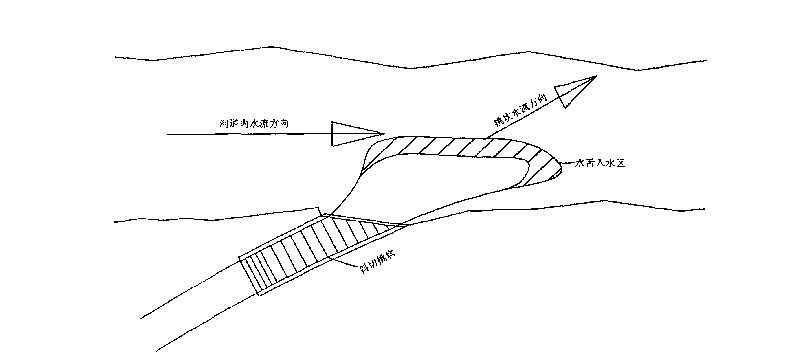

Embodiment 1

[0021] like figure 2 As shown, the reverse oblique cutting ridge provided in this embodiment is composed of a bottom plate 1 and side walls 2 erected along both sides of the bottom plate. The length of the wall 2 and the base plate 1, the edge of the base plate 1 between the ends of the two side walls 2 forms a hypotenuse, and the side wall 2 is a straight line, and the base plate 1 is a curved surface of equal width and curvature.

Embodiment 2

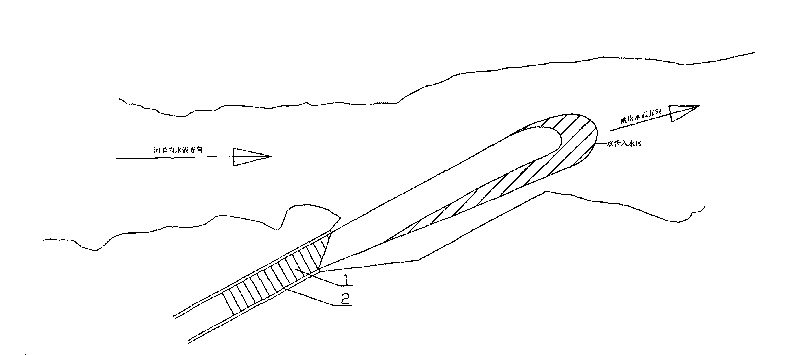

[0023] like image 3 As shown, the reverse oblique cutting ridge provided in this embodiment is also composed of the bottom plate 1 and the side walls 2 erected along both sides of the bottom plate. The length of the side wall 2 and the bottom plate 1 is that the edge of the bottom plate 1 between the ends of the two side walls forms a hypotenuse, and the bottom plate 1 is a curved surface of equal width and equal curvature, but the difference from Embodiment 1 is that the side wall 2 is curve, see Figure 4 .

Embodiment 3

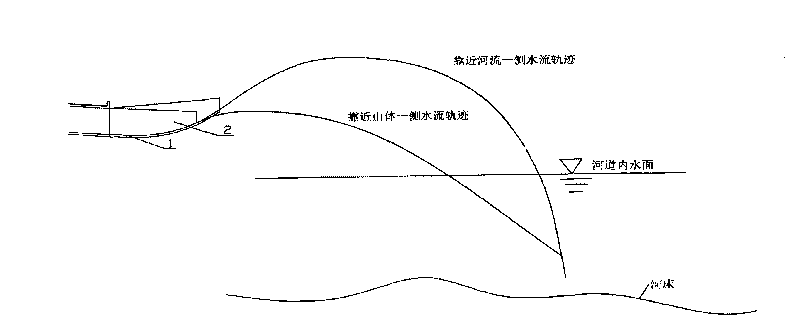

[0025] like Figure 4 As shown, the reverse oblique cutting ridge provided in this embodiment is also composed of the bottom plate 1 and the side walls 2 erected along both sides of the bottom plate. The length of the side wall 2 and the bottom plate 1, the edge of the bottom plate 1 between the ends of the two side walls 2 forms a hypotenuse, and the side wall 2 is a curve, but the difference from embodiment 2 is that the bottom plate 1 is twisted with unequal width To meet with Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com