Multistage over fire air distributing mode

A technology of burn-out air and separation of burn-out air, which can be used in combustion methods, combustion equipment, and incombustible liquid/gas transportation. , Improve combustion efficiency and achieve the effect of low NOx emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

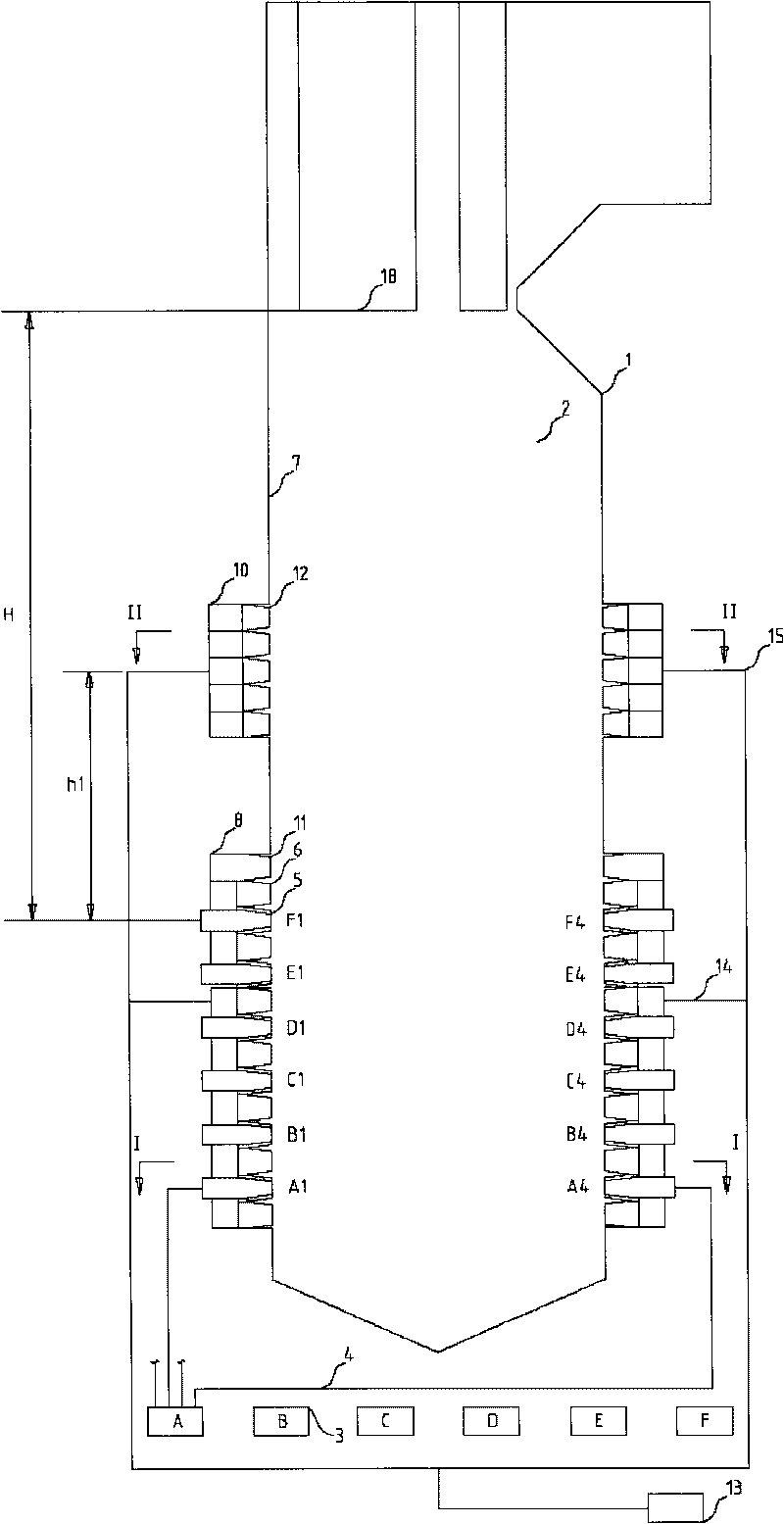

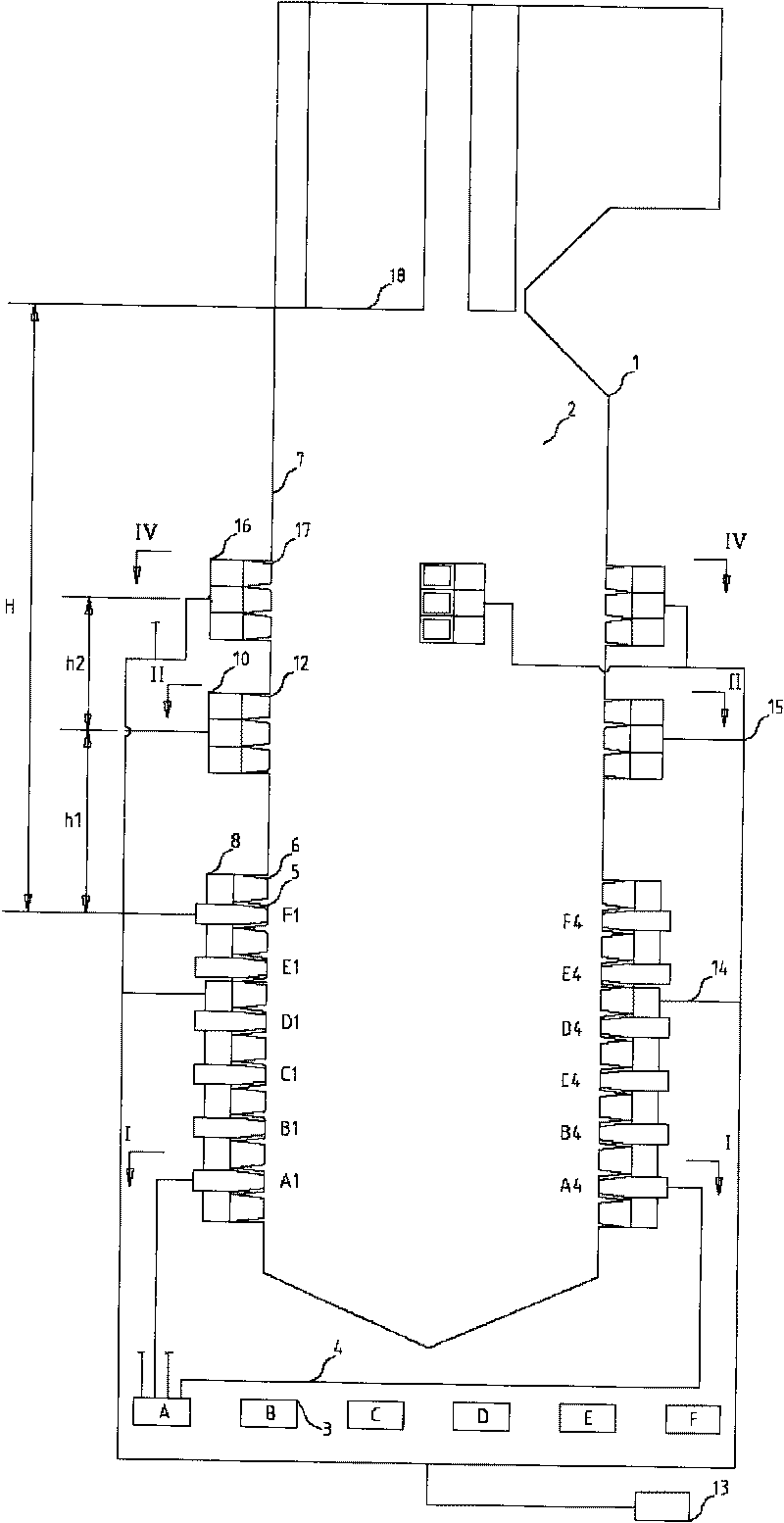

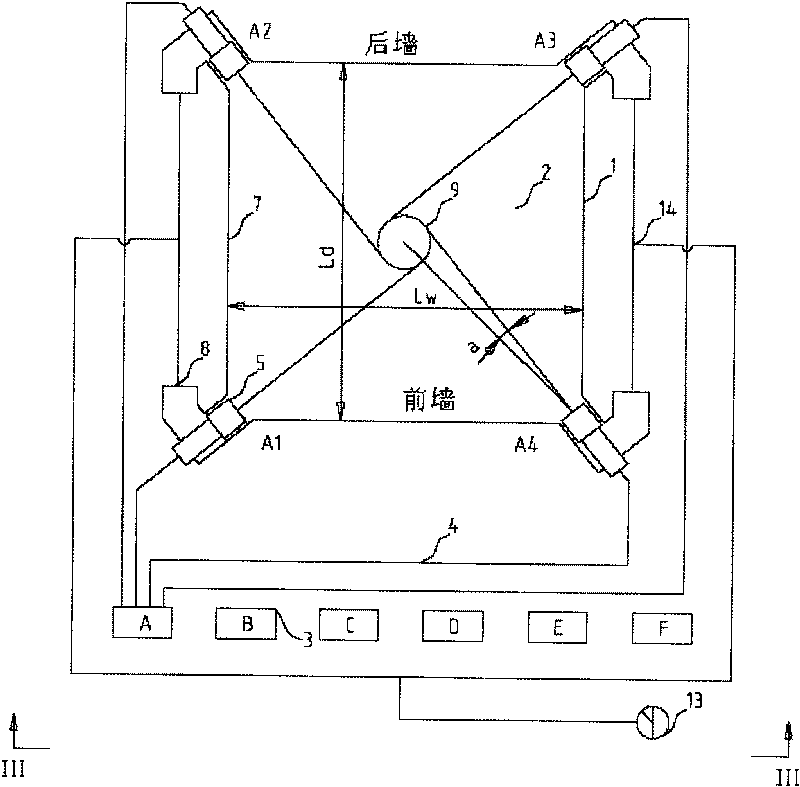

[0039] to combine figure 2 , image 3 , Figure 4 with Figure 5 To describe this embodiment, image 3 for figure 2 I-I sectional view, Figure 4 for figure 2 II-II sectional view, Figure 5 for figure 2 Sectional view of IV-IV, figure 2 for image 3 , Figure 4 with Figure 5 Sectional view of III-III.

[0040] A multi-stage burn-off air arrangement method provided by the present invention includes a boiler body 1, a furnace 2, a coal mill 3, a pulverized coal pipeline 4, a primary air pulverized coal nozzle 5, a secondary air nozzle 6, a main burner 8, a low-level Separation overburning air wind box 10, high separation overburning air wind box 16 and furnace horizontal outlet panel superheater 18. Each boiler 1 is equipped with six coal mills 3 . The furnace 2 is composed of four water-cooled walls 7, and a group of main burners 8 are arranged on each corner of the furnace 2, and each group of main burners 8 is vertically arranged with six primary air pulv...

Embodiment 2

[0053] to combine Image 6 with Figure 7 To describe this embodiment, Figure 7 for Image 6 The V-V sectional view, Image 6 for Figure 7 Sectional view of III-III.

[0054] The difference between this embodiment and Embodiment 1 is that the rotation direction of the first high-level imaginary tangent circle 20 formed by the center line of the high-level separation burn-off air nozzle 17 arranged on the four walls is the same as that of the imaginary tangent circle 9 of the main burner 8 and The direction of rotation of the low imaginary tangent circle 19 of the low separation burnout air box 10 is opposite, see Figure 7 .

[0055] At the same time, the distance L1 between the centerline of the high-level separation burn-off air nozzle 17 arranged on the front and rear walls and the centerline of the water-cooled wall 7 is a quarter of the width Lw of the furnace 2 from the nearest corner of the furnace 2, Namely: L1=1 / 4Lw, see Figure 7 . Similarly, the distance ...

Embodiment 3

[0059] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the high-level separation overfire air is arranged in a circle with four corners. Other structures and test results are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com