Method for measuring tyre size

A measurement method and tire technology, applied in the field of rubber machinery, can solve the problems of inaccurate image effect, inaccurate measurement, loss of detection significance, etc., and achieve the effect of improving positioning and image quality, and accurate measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

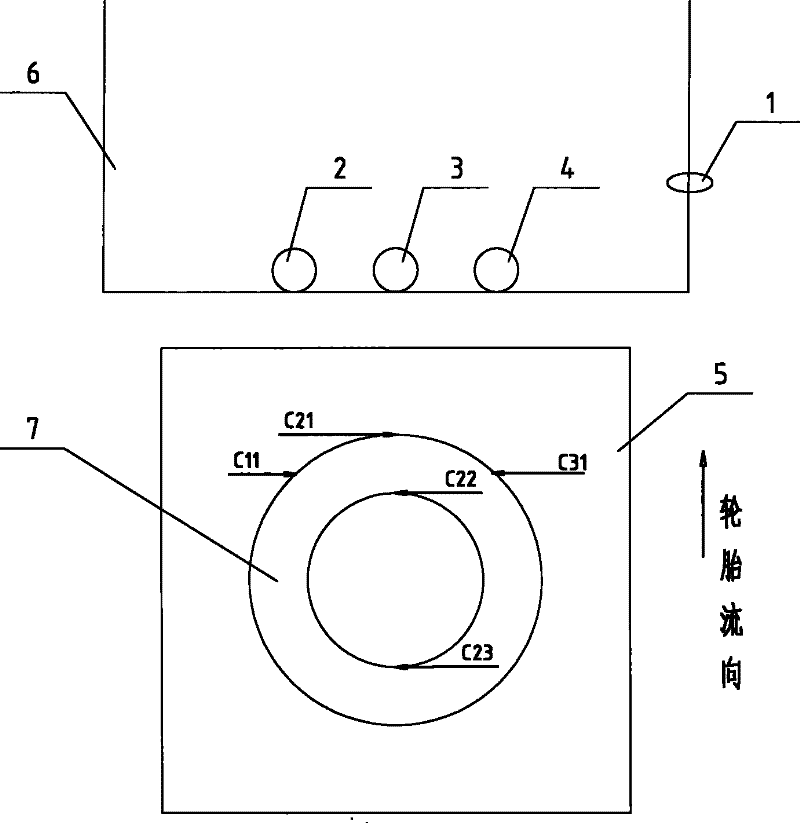

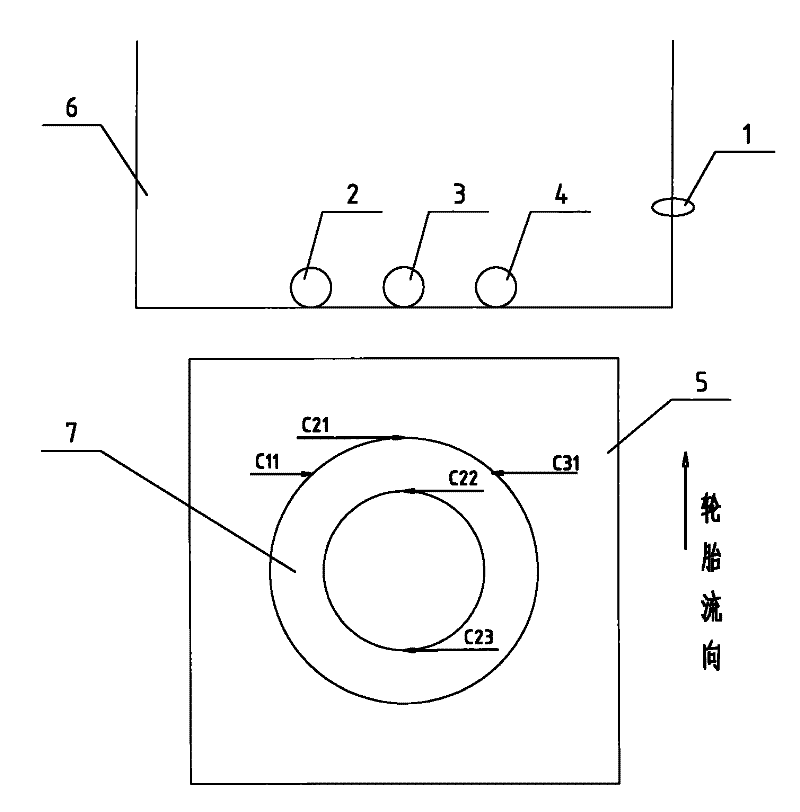

[0026] Example 1, such as figure 1 As shown, the tire specification measurement method applied to the laser speckle inspection equipment 6 measures the inside and outside of the tire 7 by establishing a corresponding linear relationship between the advancing distance of the conveyed tire 7 and the number of pulses actually measured by the rotary encoder 1. Radius value.

[0027] Simultaneously, also realize a kind of correction method of checking whether the tire 7 placed on the conveyer belt 5 has deviation.

[0028] When performing specification measurement, it is necessary to ensure that the tire 7 will not be displaced or slipped relative to the conveyor belt 5 during the entire conveying process, that is, the tire 7 and the conveyor belt 5 are required to remain relatively stationary to ensure that the rotary encoder 1 actually measures Accurate pulse value improves measurement accuracy.

[0029] Above the entrance of the laser speckle inspection device 6, three photoel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com