Semiconductor device and manufacture method thereof

A manufacturing method and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as deterioration, punch-through effect electrical performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The inventors found that because the existing MOS transistors use ultra-shallow junction technology to make the source / drain region in order to overcome the short channel effect, but the implanted ions in the source / drain region will cause diffusion and penetration, which will cause the source / drain region Junction capacitance and junction leakage lead to punch-through effect between source / drain regions, affecting the quality of MOS transistors.

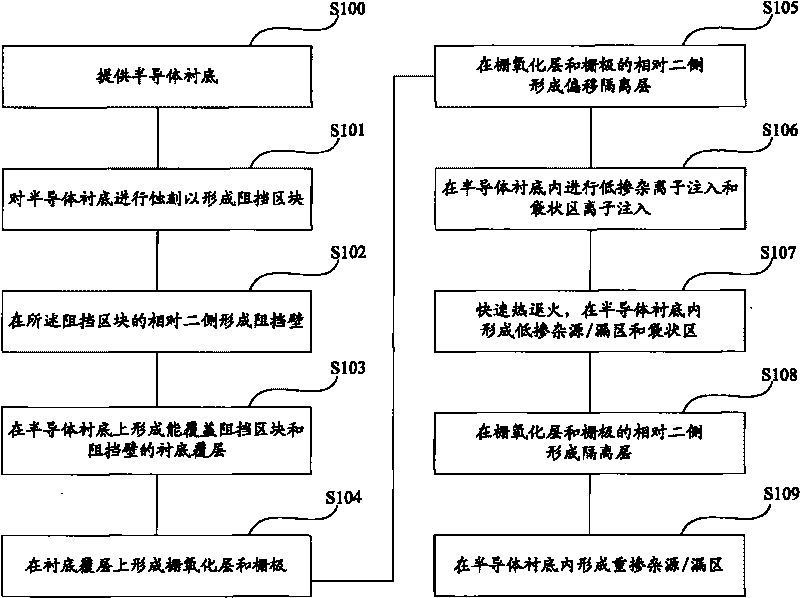

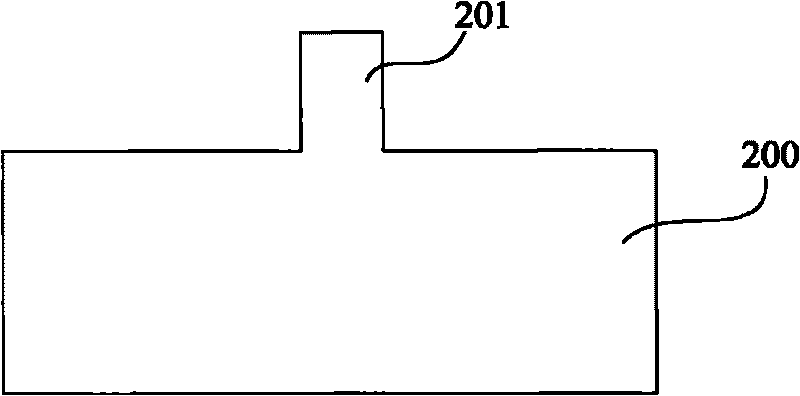

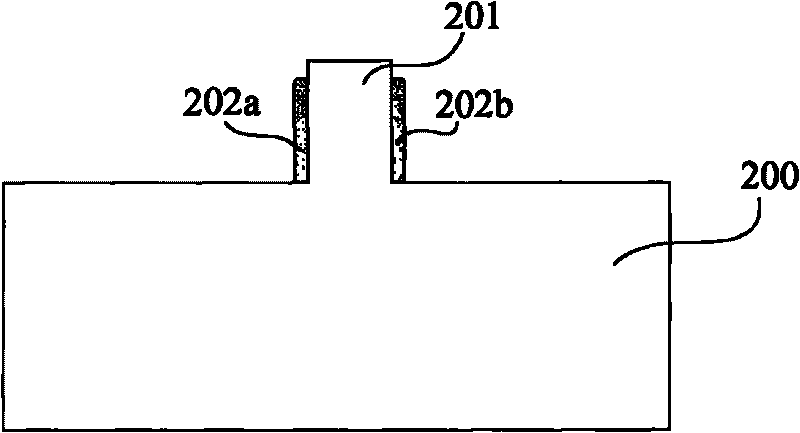

[0028] Therefore, in the manufacture of semiconductor devices, in order to prevent the occurrence of the above-mentioned defects. In the present invention, the provided semiconductor substrate is firstly etched to form a barrier block; barrier walls are formed on opposite sides of the barrier block; a substrate covering capable of covering the barrier block and the barrier wall and integrated with the semiconductor substrate is formed. layer, the barrier wall has a drop from the surface of the substrate cladding layer; a gate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com