Manufacturing method of metal-oxide-semiconductor field effect transistor (MOSFET)

An oxide semiconductor and field effect transistor technology, applied in the field of metal oxide semiconductor field effect transistor fabrication, can solve the problems of increasing the short-channel effect of the conductive channel, reducing the short-channel effect, etc., so as to avoid the short-channel effect , The effect of reducing leakage current and improving device life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

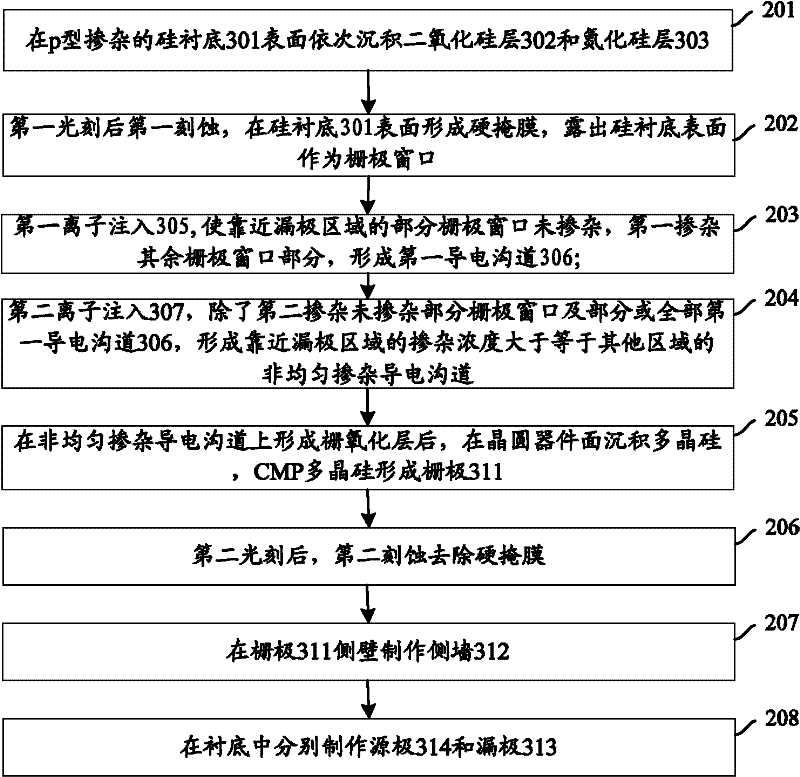

[0023] A kind of manufacture method of N-type MOSFET, below in conjunction with attached Figure 3a~3h , detailing the specific steps for fabricating N-type MOSFETs.

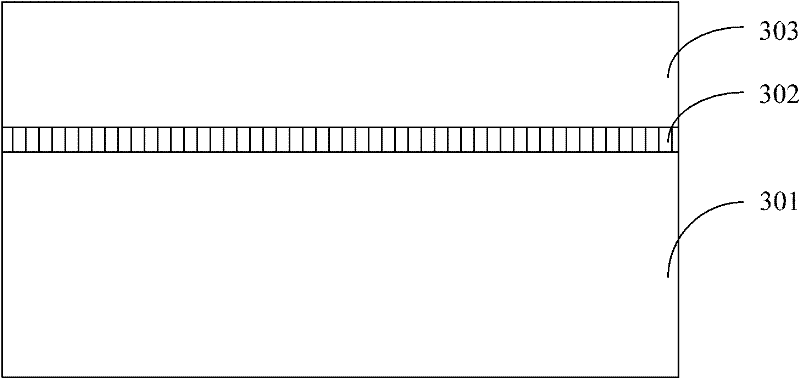

[0024] Step 201, Figure 3a It is a schematic cross-sectional structure diagram of step 201 of the N-type MOSFET manufacturing method of the present invention, such as Figure 3a As shown, a wafer with a p-type doped silicon substrate 301 is provided, a source region and a drain region are arranged in the silicon substrate 301, and a silicon dioxide layer 302 and silicon nitride are sequentially deposited on the surface of the silicon substrate 301 Layer 303;

[0025] This embodiment takes the manufacturing method of N-type MOSFET as an example, so a p-type doped silicon substrate 301 is used; if it is a manufacturing method of P-type MOSFET, an n-type doped silicon substrate is used.

[0026] In this step, the stacked structure of silicon dioxide layer 302 and silicon nitride layer 303 is used as the first d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com