Self temperature compensation circular waveguide resonant cavity

A circular waveguide and temperature compensation technology, applied in resonators, waveguide devices, electrical components, etc., can solve the problems that the influence of temperature on the resonant frequency of the resonant cavity cannot be greatly reduced, and the equipment is complicated, so as to achieve simple structure and applicable The effect of a wide frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

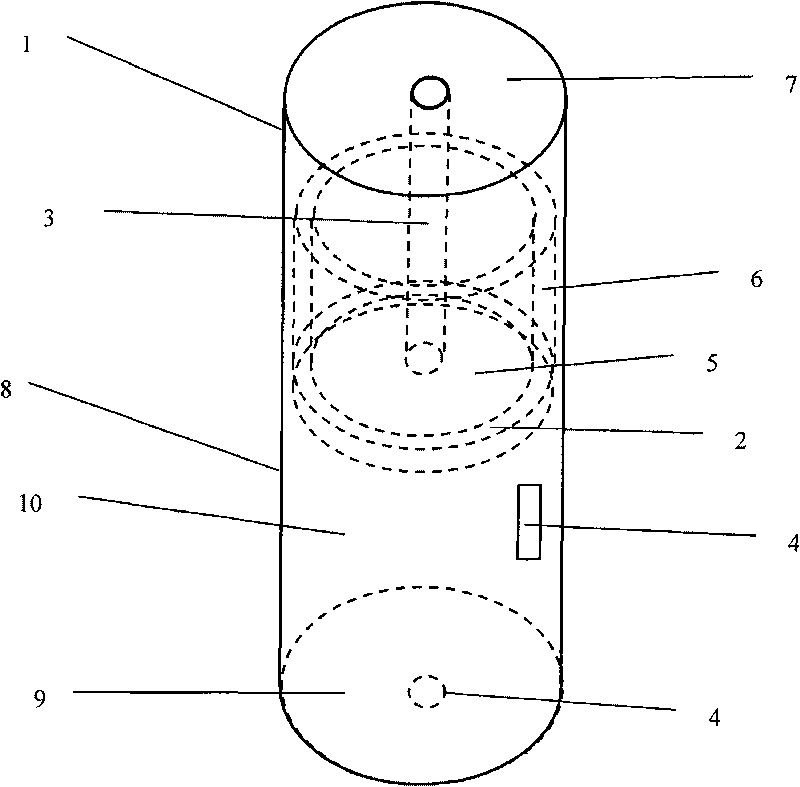

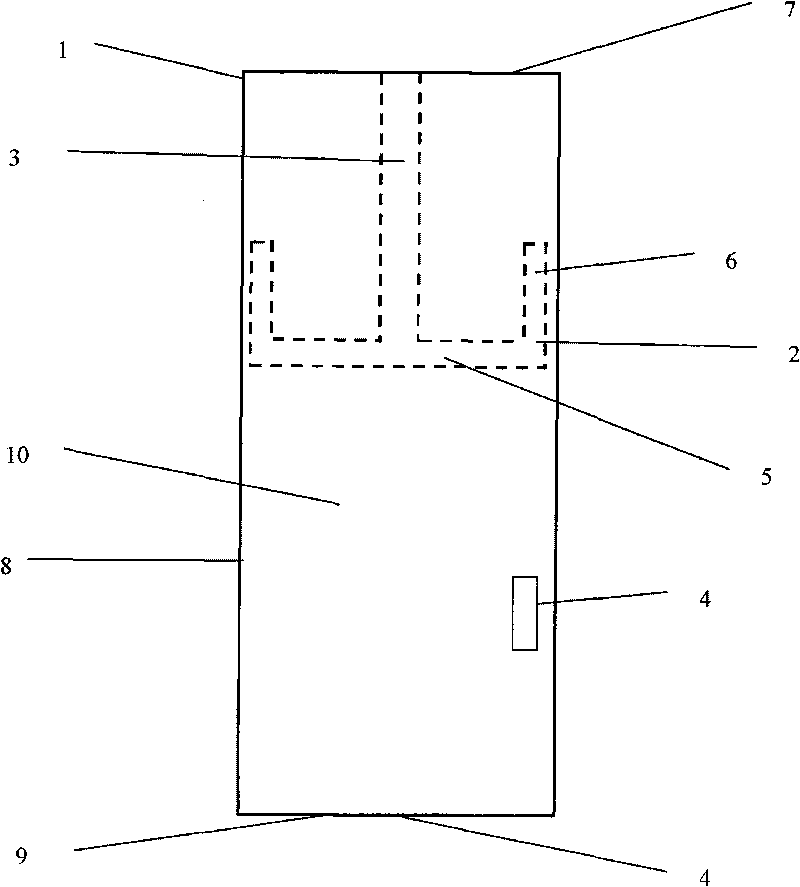

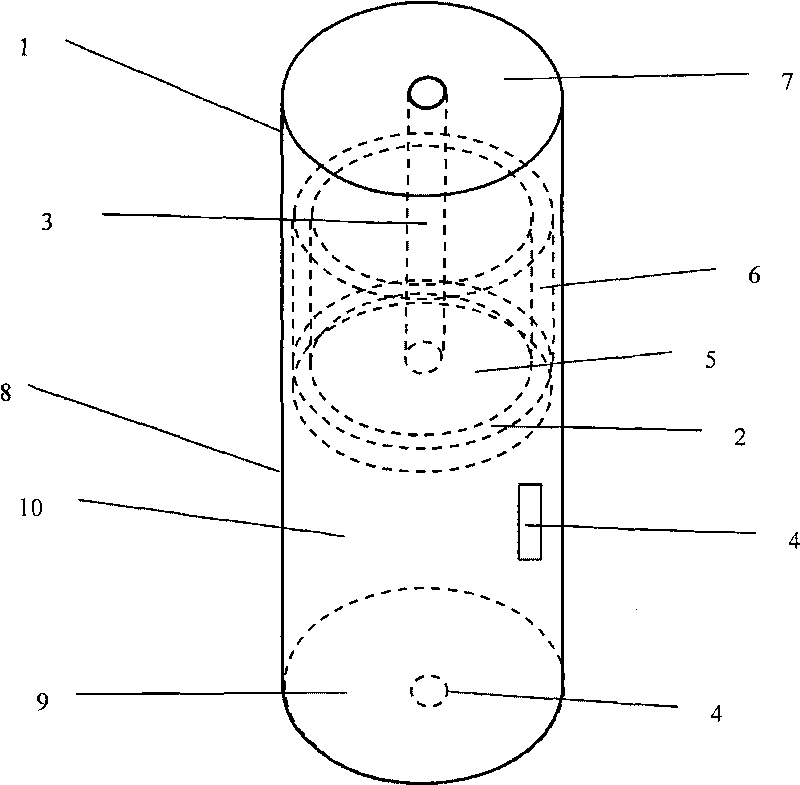

[0009] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0010] The technical scheme adopted in the present invention is that the self-temperature-compensated circular waveguide resonant cavity includes a metal cavity, a short-circuit cylinder, a support body connecting the bottom surface of the cylindrical metal cavity and the bottom of the short-circuit cylinder, and one or more input and output coupling devices. The shape of the metal cavity is a cylinder. The material of the short-circuit cylinder can be the same material as the metal cavity, or other conductive metal materials, and metal can also be plated on the surface of non-metallic materials. The short-circuit cylinder consists of a circular bottom surface and a cylindrical cylinder wall. The bottom surface of the short-circuit cylinder is circular, and the bottom surface is connected to a bottom surface cavity wall of the cylindrical metal cavity thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com