Three-phase synchronous reluctance motor

A reluctance motor, three-phase synchronization technology, applied in the field of electric motors, can solve the problems of high cost, not smooth output torque, and high electromagnetic noise, and achieve the effects of high material utilization, reduction of electromagnetic noise, and avoidance of output pulsating torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

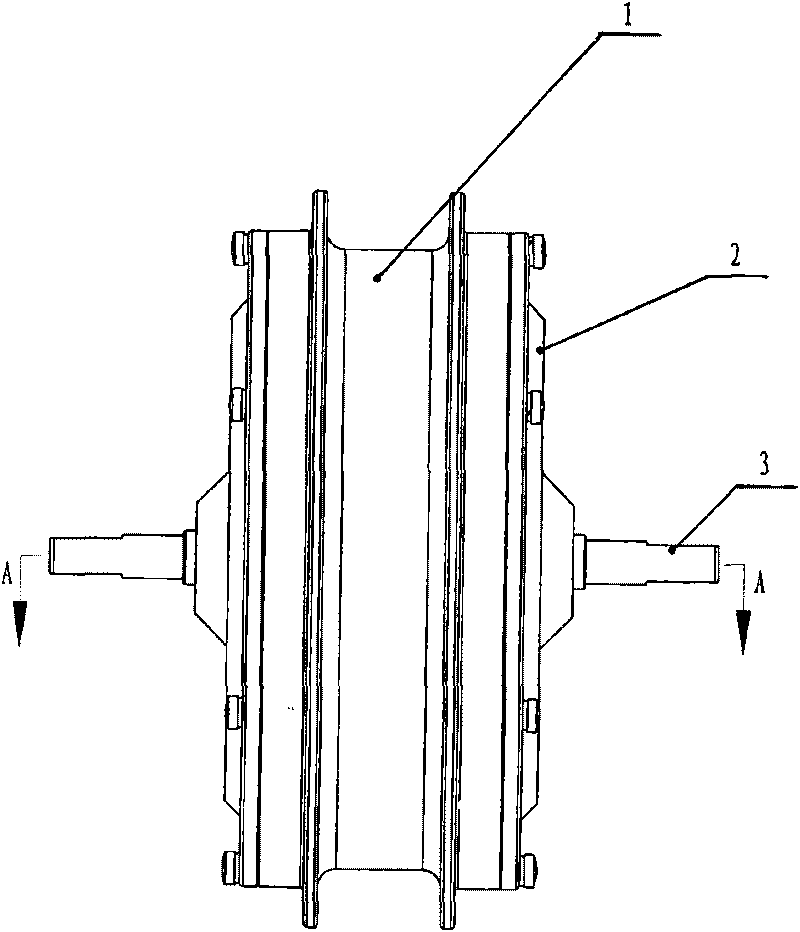

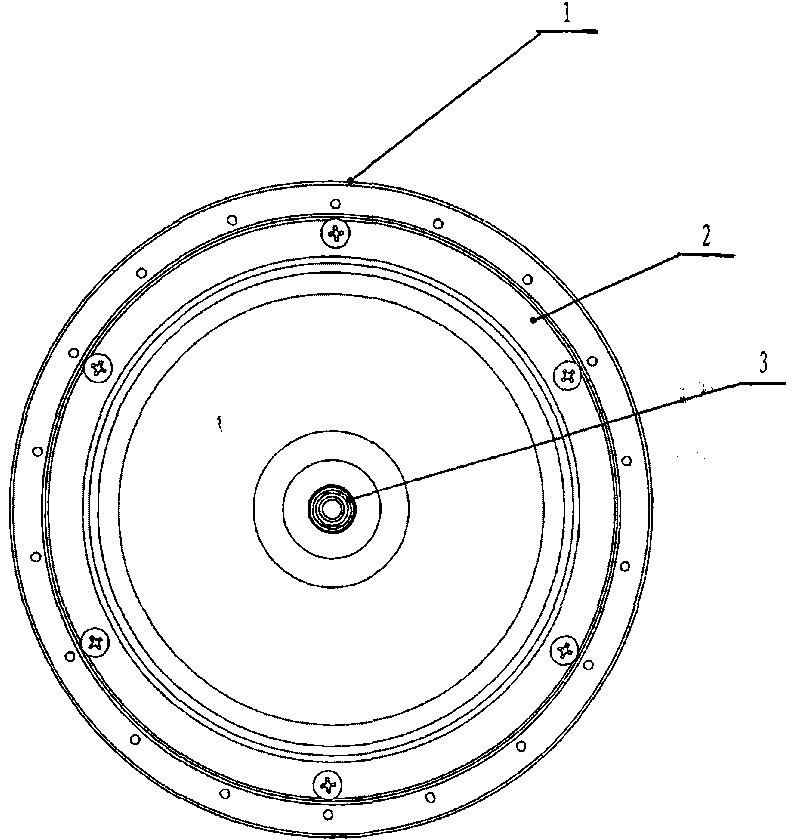

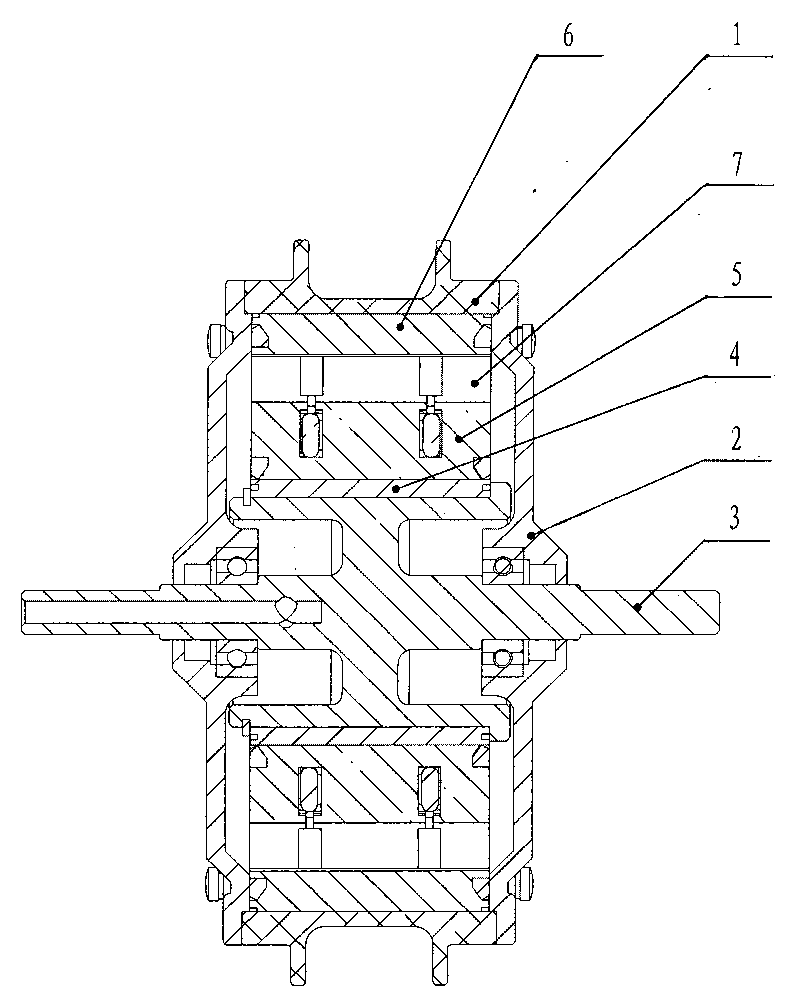

[0031] A three-phase synchronous reluctance motor, including a stator assembly, a rotor assembly, a wheel housing 1, an end cover 2 fixed at both ends of the wheel housing 1, and a stator shaft 3; the end cover 2 is supported on the end of the stator shaft 3 through a bearing; the stator assembly consists of The stator coil 4 fixed on the stator shaft 3, 6N (N is a natural number greater than or equal to 2) stator poles 5 fixed on the stator coil 4, and concentrated windings wound on each stator pole 5; the rotor assembly includes and The rotor ring 6 fixed by the wheel shell 1, the 7N (N is a natural number greater than or equal to 2) rotor poles 7 fixed on the rotor ring 6, and the permanent magnets fixed on the rotor poles 7; among the 6N concentrated windings, each consecutive The six concentrated windings of each group of six concentrated windings, the tail end of the first concentrated winding is connected with the tail end of the fourth concentrated winding as A-phase wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap