Industrial electromagnetic induction heating device

An electromagnetic induction heating, industrial technology, applied in the direction of induction heating devices, induction heating, coil devices, etc., can solve the problems of abnormal control temperature, waste of heating energy, low efficiency, etc., to ensure equipment and personal safety, save energy, simplify Effect of thermal settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

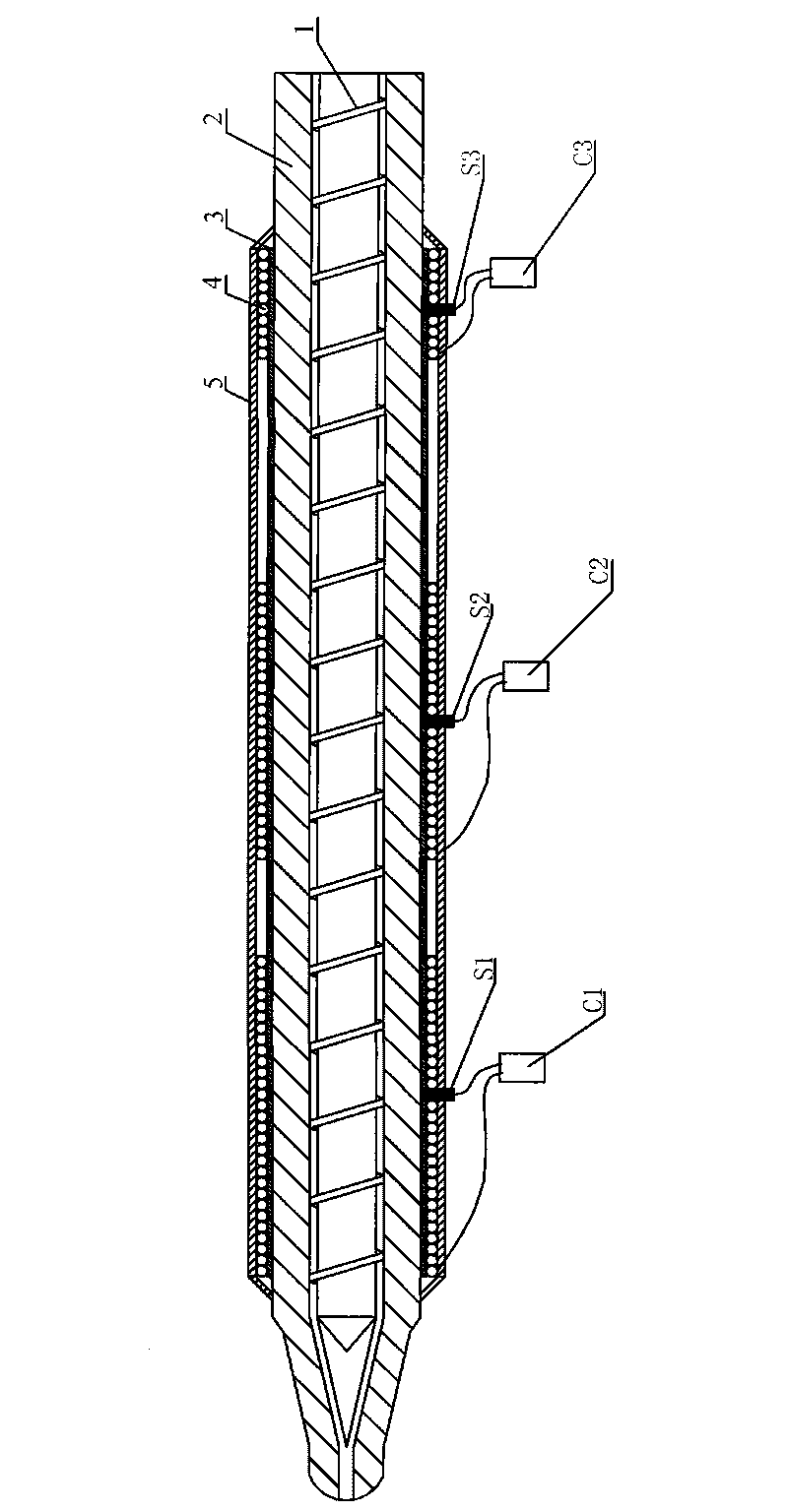

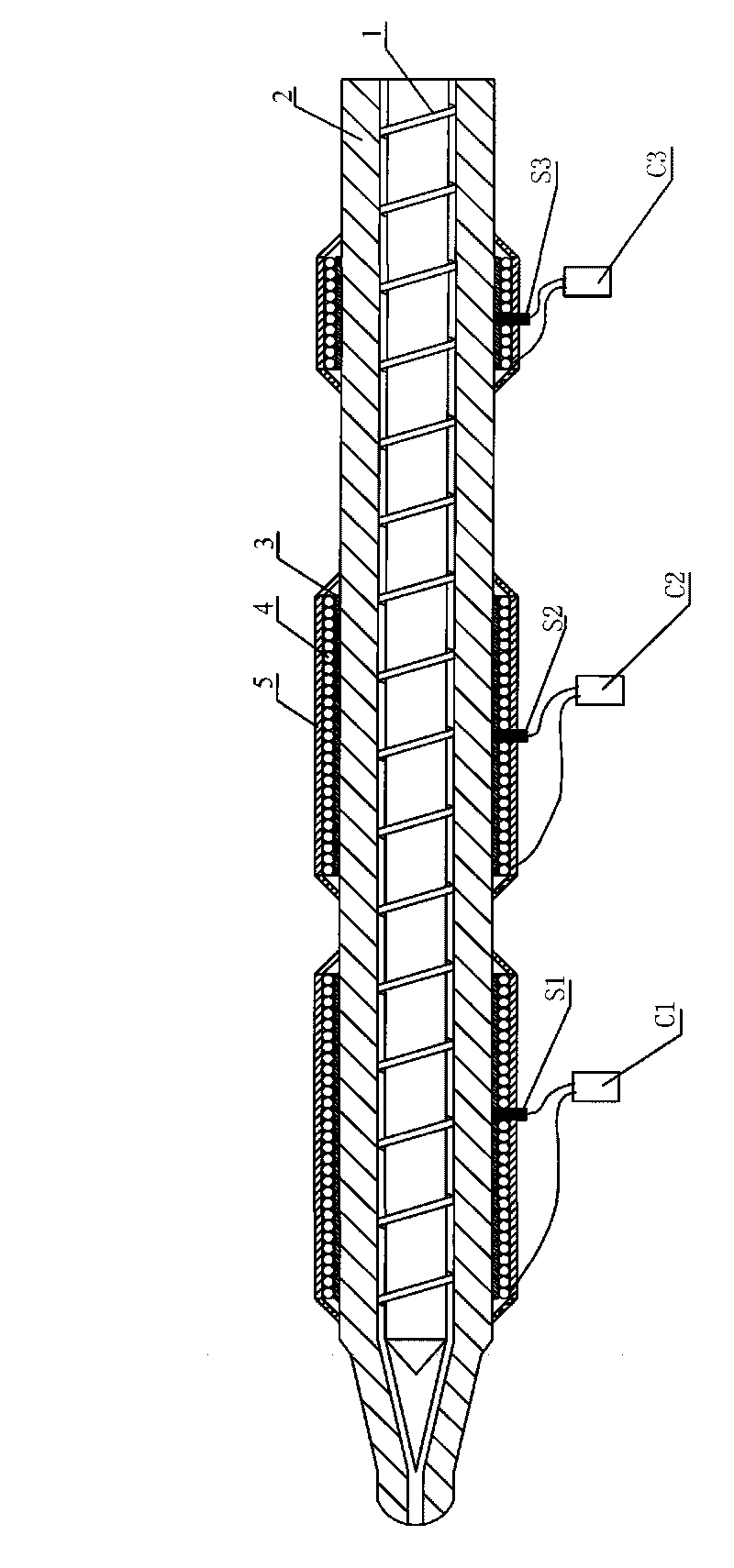

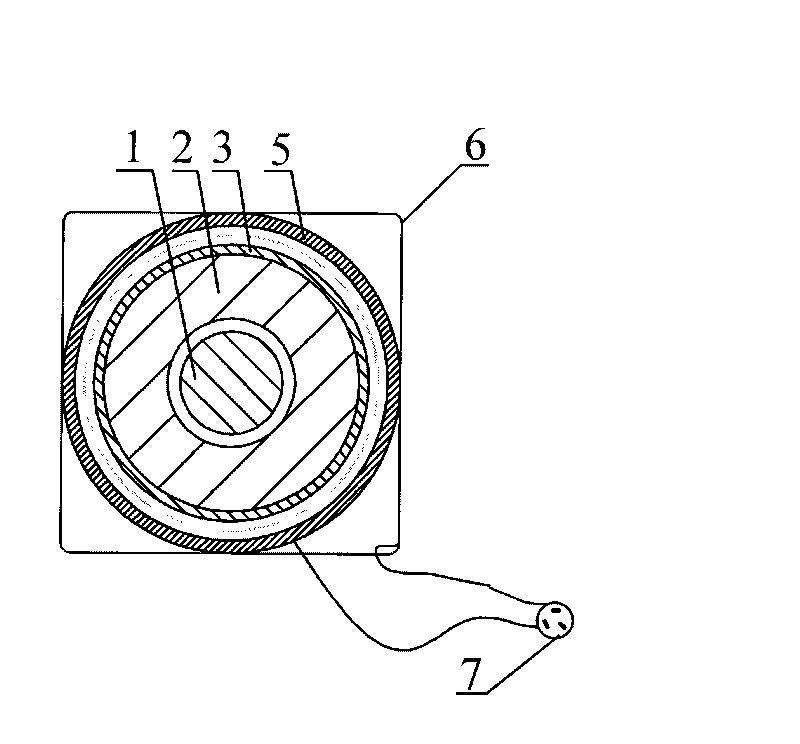

[0028] Such as figure 1 As shown in the industrial electromagnetic induction heating equipment with a safety shielding device, the screw 1 is placed in the barrel 2, the outer circle of the barrel 2 is provided with an insulating layer 3, and the electromagnetic coil 4 is wound on the insulating layer 3, The electromagnetic coil 4 uses different power electromagnetic coils to heat according to the heat demanded by the heating. The operating frequency of the electromagnetic coil 4 is 10KHZ ~ 99KHZ; a complete electromagnetic shielding layer 5 is arranged around the electromagnetic coil 4, and the electromagnetic shielding layer 5 The electromagnetic shielding layer 5 is connected to the electromagnetic elimination device. The electromagnetic elimination device is a connecting wire connected to the neutral wire of the power supply or the ground wire of the equipment. It adopts a direct grounding wire or a single-phase The zero line of the three-claw power plug is connected; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com