Pneumatic seed shooting and seeding device

The technology of a seeding device and a seeding device, which is applied in the field of agricultural machinery, can solve problems such as reducing the working efficiency of openers, difficulty in ensuring seeding quality, and unfavorable soil protection, so as to achieve environmental protection, reduce the number of plowing times, and reduce energy consumption. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

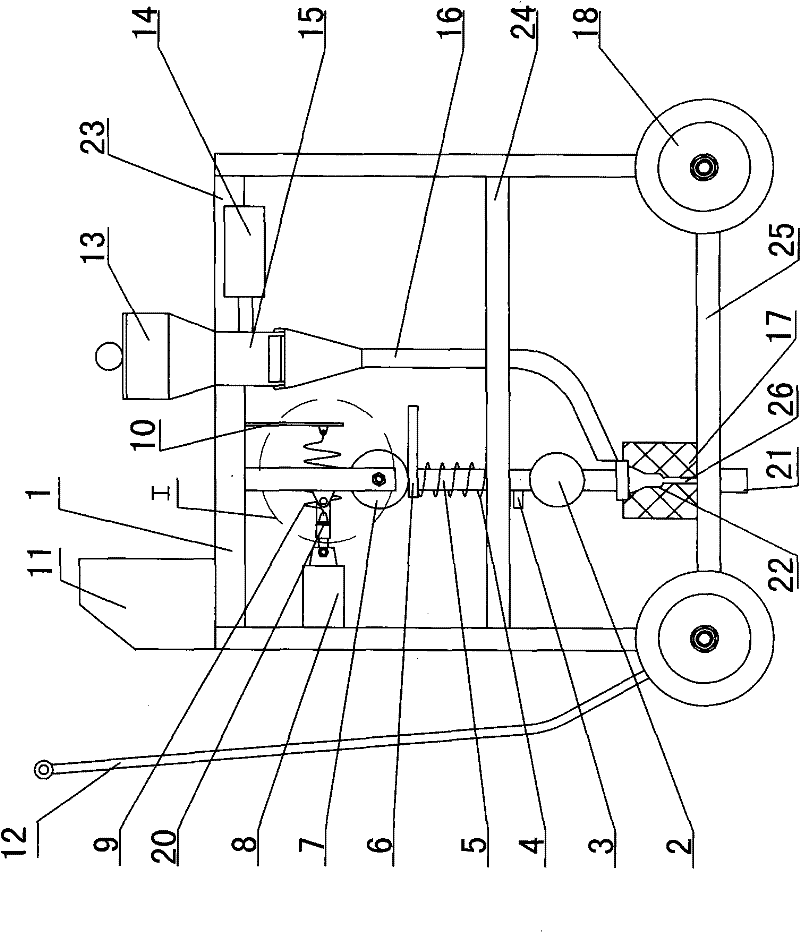

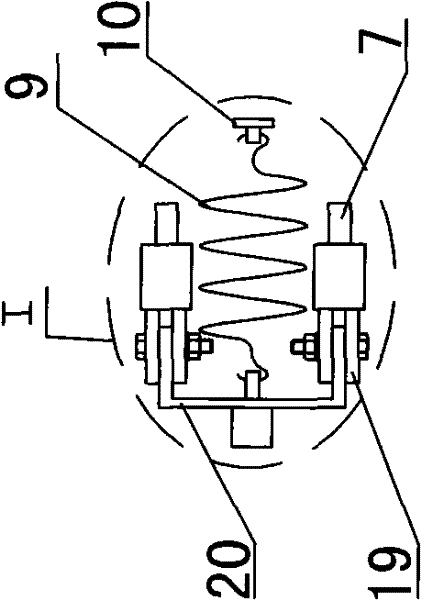

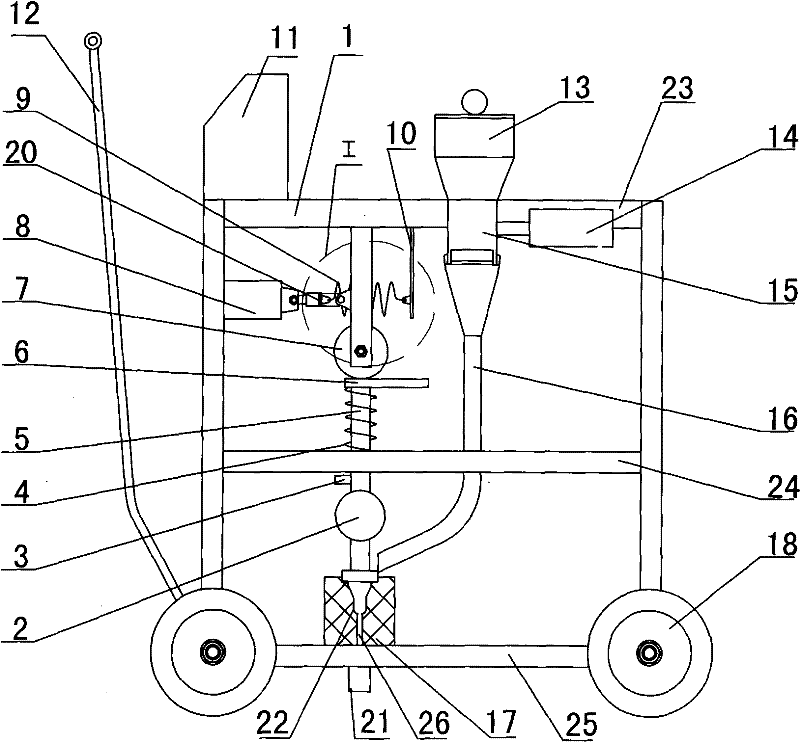

[0013] Such as Figure 1-2 In the shown embodiment: the PLC controller 11, the seed box 13 and the stepper motor 14 are all installed on the upper partition 23 of the frame 1, the hole seed meter 15 is installed at the bottom of the seed box 13, and the bottom is provided with a Seed tube 16, the output shaft connection type hole seed meter 15 of the stepper motor 14; the drive module includes a traction electromagnet 8 fixed on the frame 1, two swing bars whose upper end is hinged with the upper partition plate 23 beam of the frame 1 19. The locking wheel 7, the grooved rocker arm 20, the tension spring 9, and the pull plate 10 fixed at the bottom of the upper partition 23 of the frame 1 are connected by a shaft at the lower end of each swing rod 19, in which the traction electromagnet 8 The control terminal of the control terminal is connected to the PLC controller 11, and the two arms of the grooved rocker arm 20 are respectively connected to the two swing rods 19 shafts, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com