Seedling dividing thresher and dust sucking device of stem-preserving type (semi-feeding) rice-wheat combine harvester

A technology for combine harvesters and dust collection devices, applied to harvesters, cutters, threshing equipment, etc., can solve problems such as reducing the service life of machines, polluting the appearance of machines, and endangering the health of operators, so as to improve work efficiency and improve Threshing cleanliness, the effect of ensuring health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

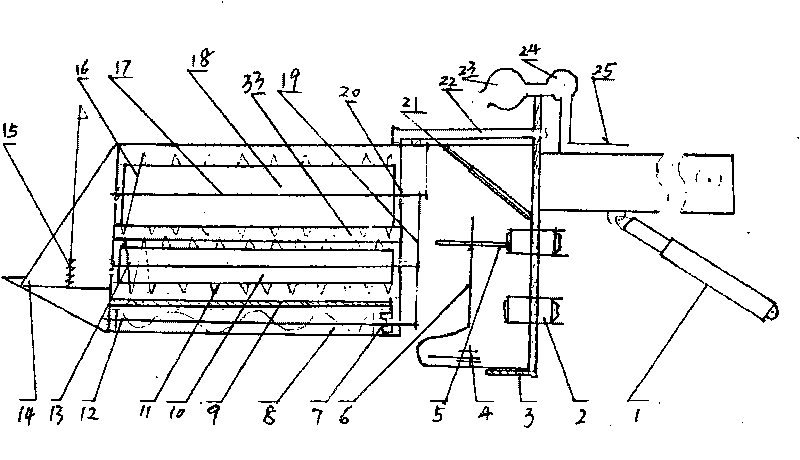

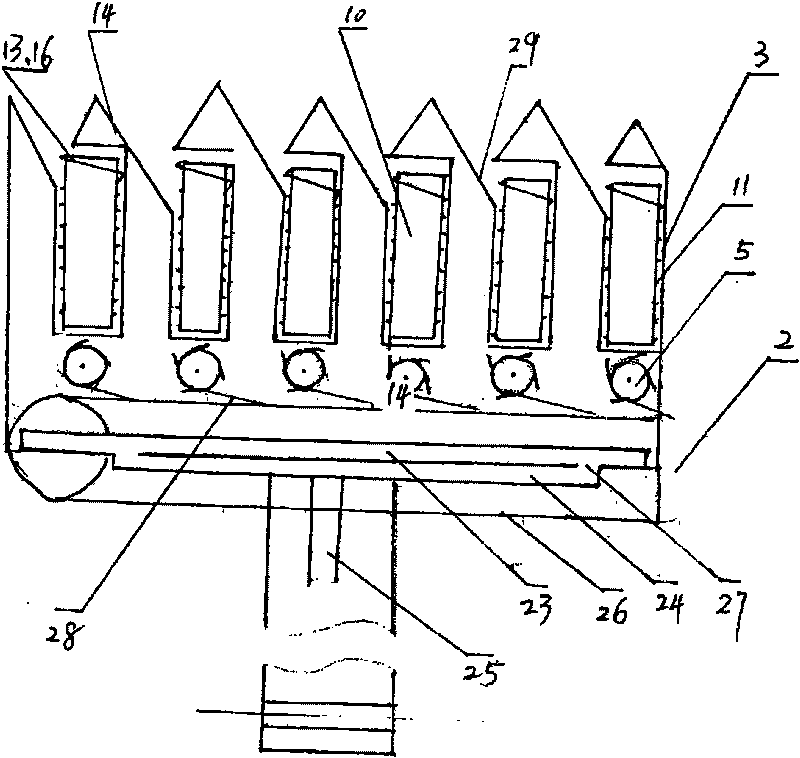

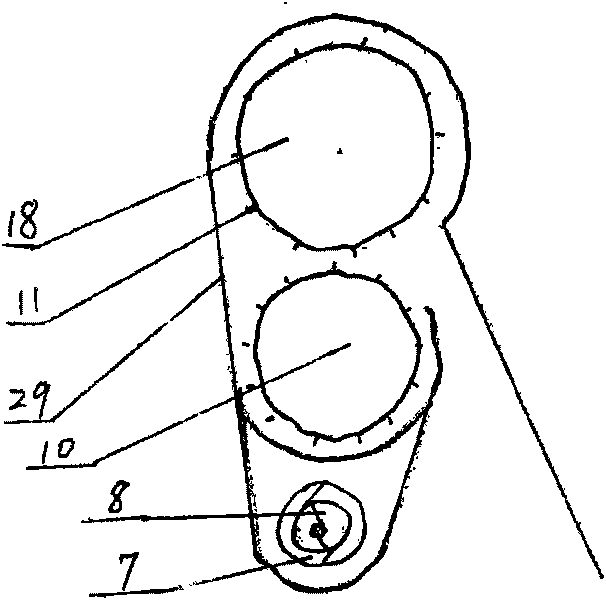

[0015] During operation, the grain divider (14) at the front end first separates the crops into ridges, and then stirs (16) the front end of the threshing drum on the upper threshing drum (18), and the threshing drum on the lower threshing drum (10). Stir the front end (13) to feed the ears of the crops into the feed port (33), and with the support of the "a" shaped grass support board (29), the combing produced by the upper and lower rollers against each other (11) , strike for threshing, and after preliminary screening by the concave plate sieve (9), the airflow generated by the grain suction fan is transported to the driver's cab by the stirring (8), the lifter (7), and the grain delivery pipe of the lifter (22). The cleaning mechanism at the end cleans again, and finally enters the warehouse. The cleaned crop stems are cut by the cutter (4), pulled out by the pulling wheel (5) and the grass pressing spring (28) and the grass pulling belt (26) mounted on the pulling wheel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com