Dripper

A dripper and drip tip technology, which is applied in the direction of making medicine into a special physical or taking form of the device, can solve the problems affecting the uniformity of the dripping pill product, the unstable flow of the liquid medicine, and the quality of the dropping pill product. It achieves the effects of simple structure, guaranteed quality of dripping pills, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

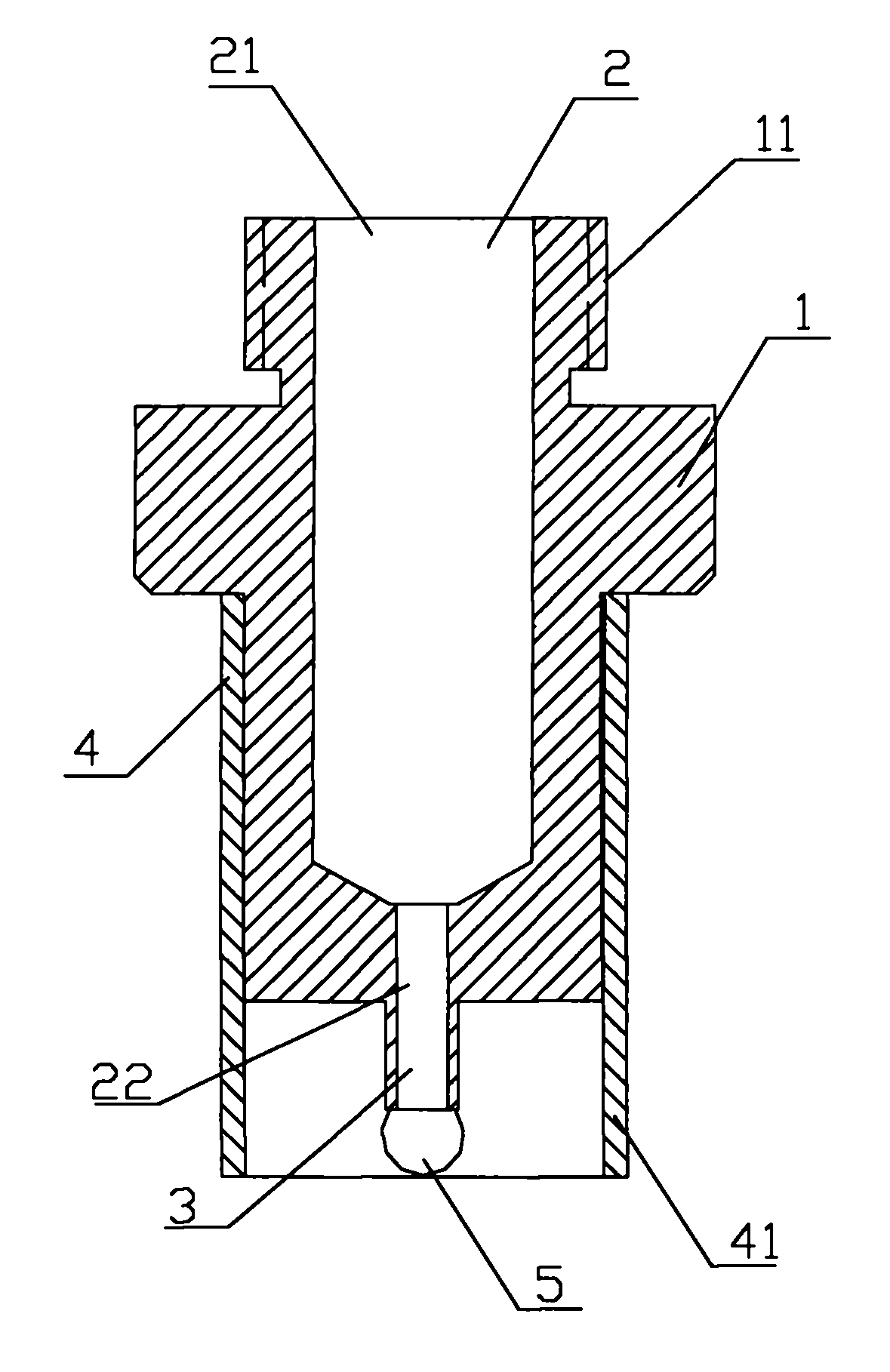

[0015] figure 1 It is a sectional view of the overall structure of the dripper of the present invention. Such as figure 1 As shown, the present invention provides a dripper, which includes a dripper body 1, and the upper end of the dripper body 1 is provided with a connection part 11 for connecting with a drip tray. The connection part 11 can adopt various existing connection structures, such as : the thread provided on the outer upper end of the dripper body 1 . The dripper body 1 is provided with a liquid medicine channel 2, and the end of the liquid medicine channel 2 is a liquid medicine drip nozzle 3, and the liquid medicine channel 2 is a variable-diameter channel, which is composed of a liquid medicine inlet 21 and a medicine liquid outlet 22 , the drip nozzle 3 is located at the end of the liquid medicine outlet 22 , and the diameter of the medicine liquid inlet 21 is larger than the diameter of the medicine liquid outlet 22 . The length of the liquid medicine outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com