Polystyrene foam forming body with high foaming multiplying factor and manufacturing method thereof

A technology of polystyrene foaming and manufacturing method, applied in the direction of coating, etc., can solve the problems of buffer performance limitation, usage limitation, inability to wash with water, etc., and achieve the effect of high impact resistance

Inactive Publication Date: 2012-01-04

NIJES ENTERPRISE

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, if the expansion ratio is large, that is, the density of the molded body is small, there will be disadvantages such as the surface of the foamed molded body is brittle and the mechanical strength is reduced, resulting in easy abrasion or damage when rubbed or impacted from the outside. The expansion ratio of polystyrene foam is mostly about 50 times

[0003] In addition, the surface of polystyrene foam moldings is prone to static electricity and dust, and oil pollution or dirt after use is easy to adhere to the surface of the foam and penetrate into the foam, and cannot be washed with water. restricted

[0004] In order to overcome these shortcomings, there are improved technologies for studying the properties of polystyrene materials, such as molecular weight, molecular weight distribution, resin particle size, etc., but the processing costs of these improved technologies are high, and their cushioning properties are still limited

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

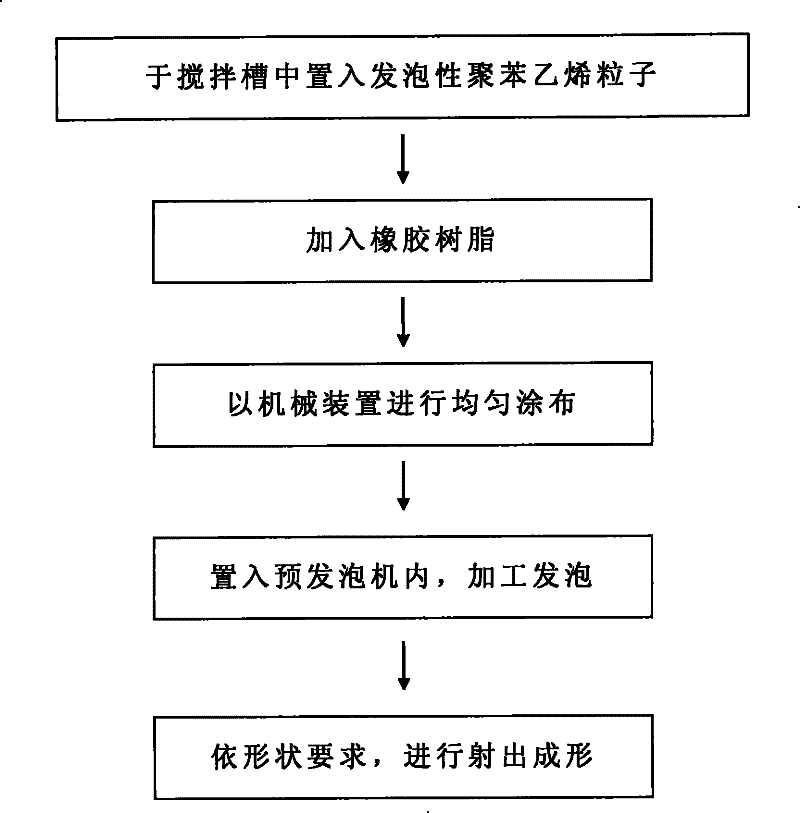

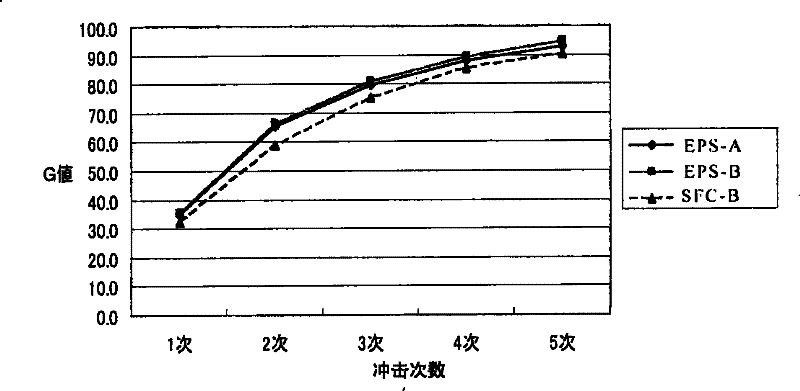

[0040] Put 11 kg of expandable polystyrene particles (EPS-B) produced by Company B into the mixing tank, add 100 g of rubber resin, coat it evenly with a film coating machine, and then put it into a 1000-liter pre-foaming machine , at a vapor pressure of 1.2kg / cm 2 , at a heating temperature of 110°C, foaming was performed at an expansion ratio of 80 times to obtain a Specially Foam Composite (SFC), hereinafter designated as SFC-B.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a polystyrene foam forming body with high foaming multiplying factor and a manufacturing method thereof. The method comprises the following steps: coating rubber resin onto the surface of foaming polystyrene particles to form a coating; sticking the rubber resin on the surface of the polystyrene particles, and then foaming; and obtaining the polystyrene foam forming body of which the foaming ratio is more than 50 times. With the method of the invention, as the surface of the polystyrene foam forming body is coated with a rubber resin layer to strengthen the cohesion thereof, the foam forming body can obtain higher impact strength, higher bending strength, higher elastic recovery ratio and the like even if foaming with 75-90 times of foaming ratio so that the foam forming body having the same volume with the tradition one can be obtained with fewer polystyrene materials so as to save material cost and achieve environment protection benefit.

Description

technical field [0001] The invention relates to a polystyrene foamed molding with a high expansion ratio and a manufacturing method thereof. Background technique [0002] Commonly used polystyrene foam molded products are widely used for packaging to protect fragile items or heat insulation for food and the like because of their excellent heat-insulating and cushioning effects. If you want to obtain lightweight polystyrene, you can lower the density by increasing the expansion ratio. However, if the expansion ratio is large, that is, the density of the molded body is small, there will be disadvantages such as the surface of the foamed molded body is brittle and the mechanical strength is reduced, resulting in easy abrasion or damage when rubbed or impacted from the outside. The expansion ratio of polystyrene foam is mostly about 50 times. [0003] In addition, the surface of polystyrene foam moldings is prone to static electricity and dust, and oil pollution or dirt after ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08J7/04C08L25/06C08J9/04

Inventor 涂集胜

Owner NIJES ENTERPRISE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com