Butt connecting component for light steel structured housing construction

A technology for steel structures and docking parts, which is applied in construction and building construction, etc., can solve the problems of a large amount of auxiliary materials, inability to realize arbitrary changes, difficult transportation and assembly, etc. requirements, to meet the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

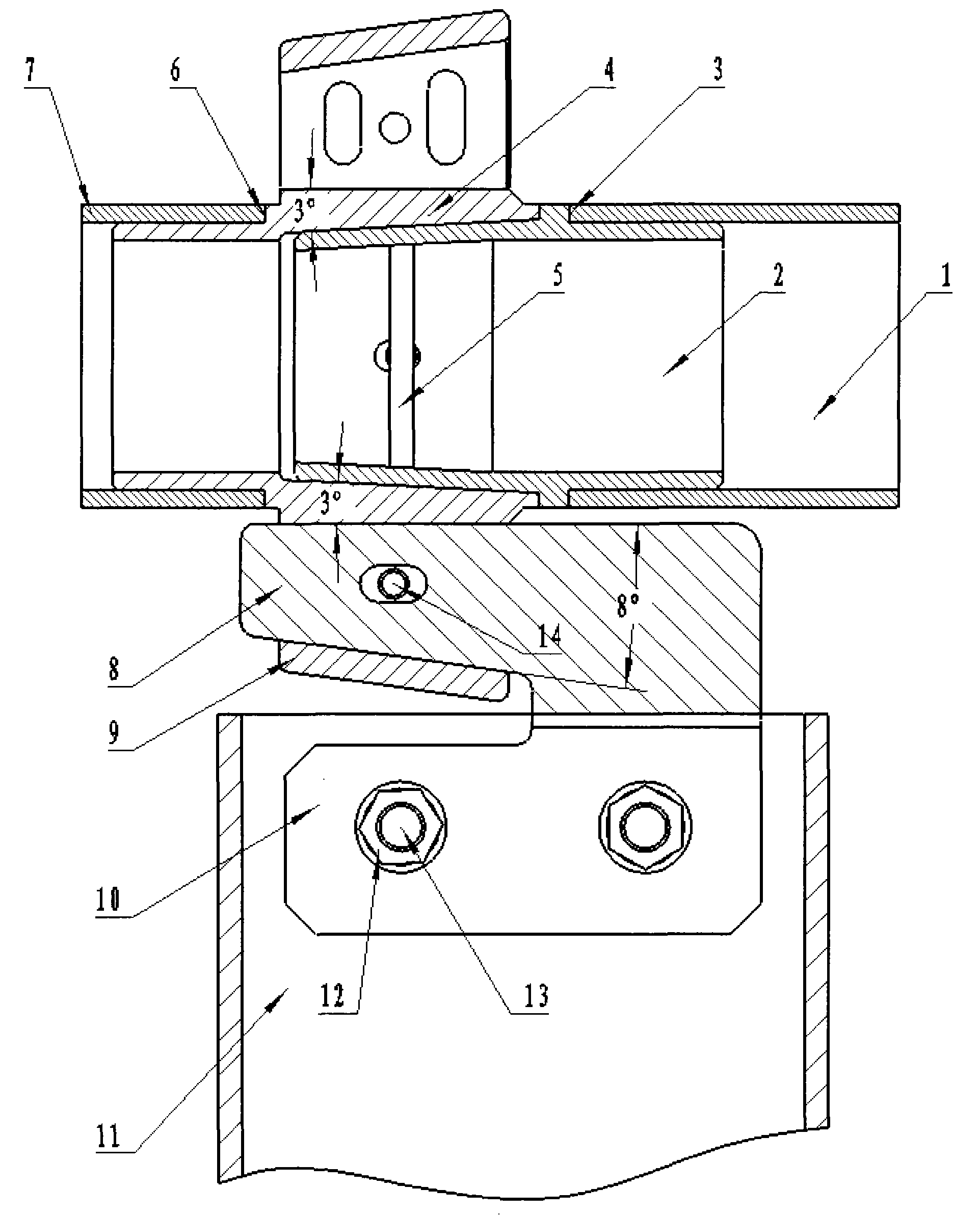

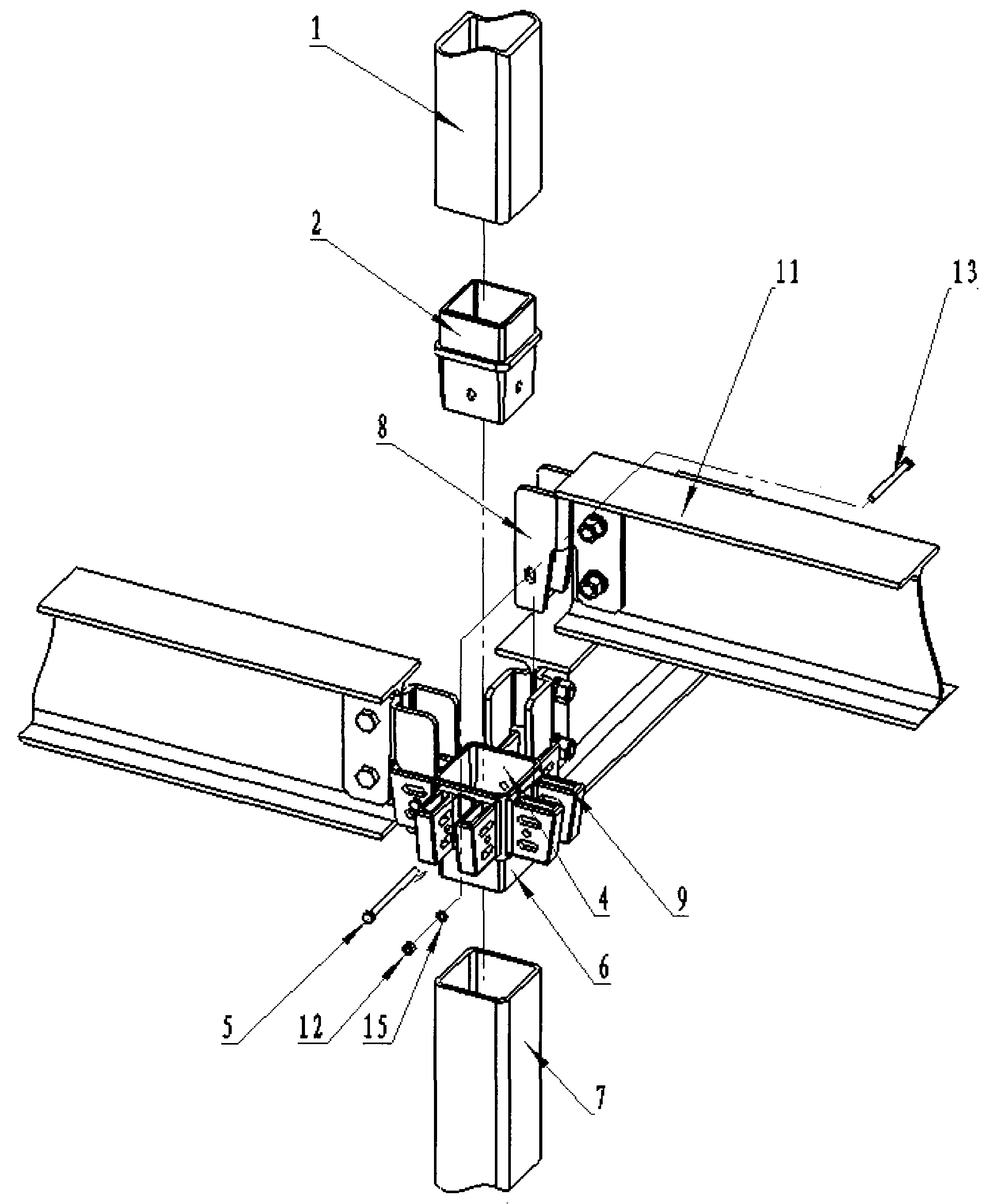

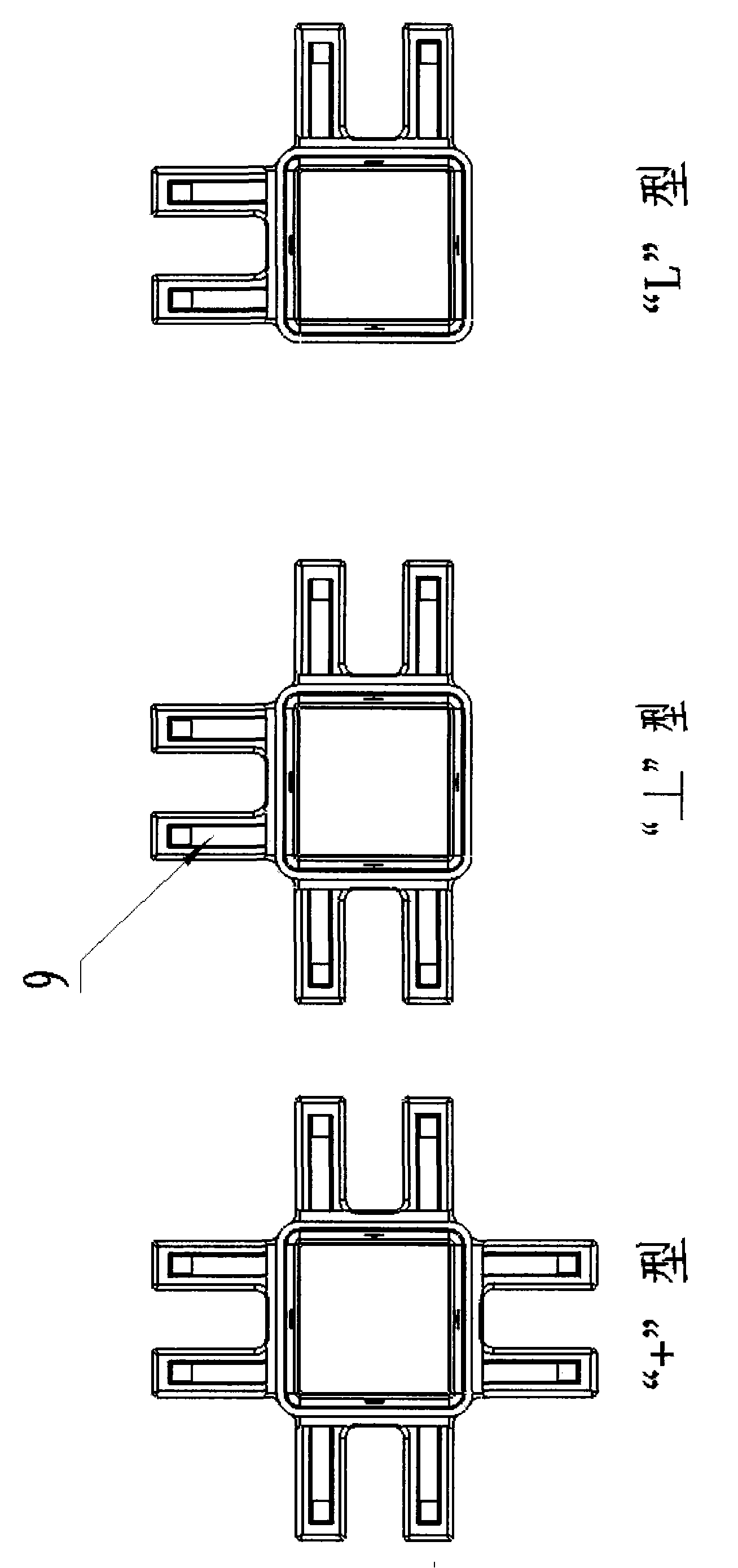

[0023] Attached below figure 1 The present invention will be described in detail. Such as figure 1 , figure 2 As shown, the upper pipe 1 is set on the outside of the upper end of the convex end combination body 2, and then welded on the periphery of the joint surface 3; Welding is carried out at the periphery; the middle part of the convex-end combination 2 has a step, and the lower end is inserted into the upper end of the concave-end combination 4; the lower end of the convex-end combination is tapered, and the taper is 3°; the convex-end combination 2 The upper end and the lower end of the concave end combined body 4 are provided with holes on the opposite surface, and the upper and lower pipes are also provided with corresponding holes. hole and perform locking treatment; the outer part of the upper end of the concave end combination is provided with an ear plate for fixing the beam 11. "Ten", "⊥" and "L" type arrangement, so that according to different requirements, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com