Wedge-shaped building method for aerated concrete blockwork top

A technology of aerated concrete and block wall, applied in the direction of walls, buildings, building components, etc., can solve the problems of easy rolling of nylon rods, unfavorable shock resistance and earthquake resistance, difficult size of nylon rod gaps, etc., to avoid heat loss and good thermal insulation. effect, the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

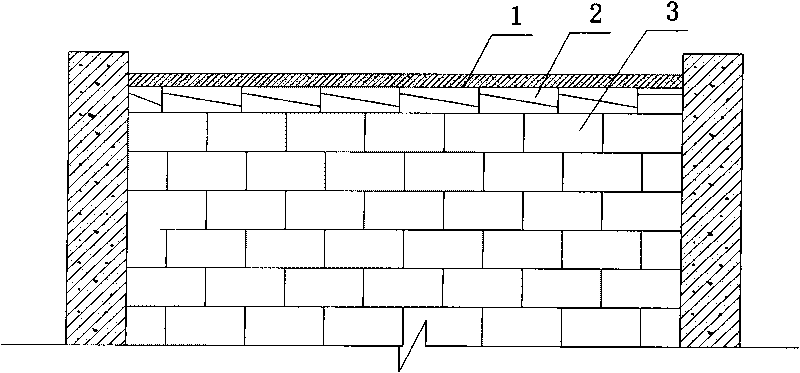

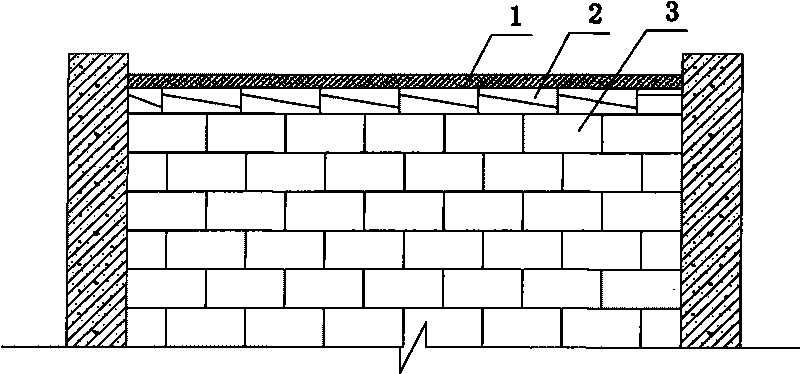

[0037] The wedge-shaped masonry method at the top of the aerated concrete block wall adopts the block masonry method, and the top of the aerated concrete block wall adopts the method of building wedge-shaped blocks.

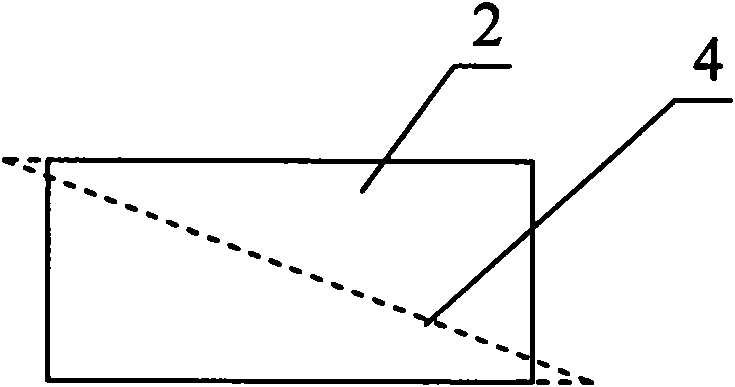

[0038] The blocks are cut into wedges along the cutting line 4, and then two wedge-shaped blocks 2 are relatively built together. The upper roof beam 1 and the lower wall body 3 are two wedge-shaped blocks and are relatively built together with the method of gluing between the top layer of the wall body. Masonry wedge-shaped block 2 adopts the knocking method to make the wedge-shaped block masonry firm and orderly. When building masonry, try to arrange the blocks in advance, and the wedge-shaped block joints and the top-layer block joints of the wall are staggered for masonry construction.

[0039] The specific construction requirements of the block masonry refer to the wall construction: the horizontal joints of the blocks should be applied to the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com