Quick fluid-discharge technology

A fast and advanced technology, applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve problems such as shallow lifting depth, low efficiency, incomplete drainage, etc., to improve operating speed and efficiency, and improve operation Low cost and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

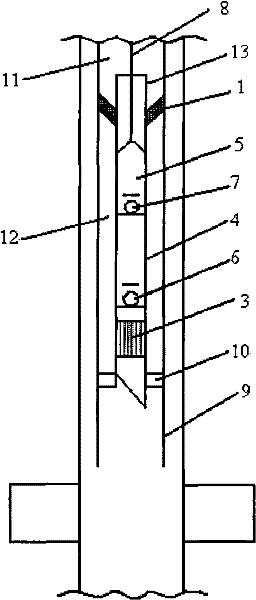

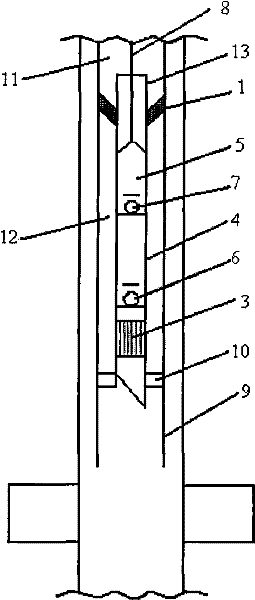

[0012] The present invention will be further described in detail below in conjunction with the embodiments: as shown in the accompanying drawings, the lower part of the sealer 1 is connected to the integrated suction pump 2, and the liquid inlet screen 3 is connected to the lower part of the integrated suction pump 2, and the sealer 1, The integrated suction pump 2 and the liquid inlet screen 3 form a liquid discharge device. The integrated suction pump 2 is composed of a pump barrel 4 and a plunger 5. There is a liquid inlet valve 6 at the lower part of the pump barrel and a liquid discharge valve 7 on the plunger. , the continuous wire rope 8 is connected with the integrated suction pump plunger. During the construction operation, the drainage device is continuously and quickly lowered to the predetermined position downhole by the continuous steel wire rope. The predetermined position is determined by the positioning ring 10 installed on the oil pipe 9. The sealer 1 isolates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com