Motorcycle cylinder jacket laser surface micro-moulding construction

A surface micro-modeling and cylinder liner technology, applied to cylinders, cylinder heads, engine components, etc., can solve the problems of slow relative speed, high working temperature, inability to set lines and pits, etc., and achieve the effect of reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

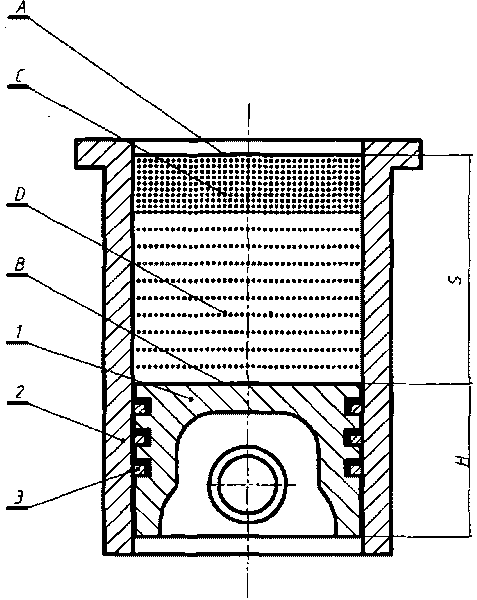

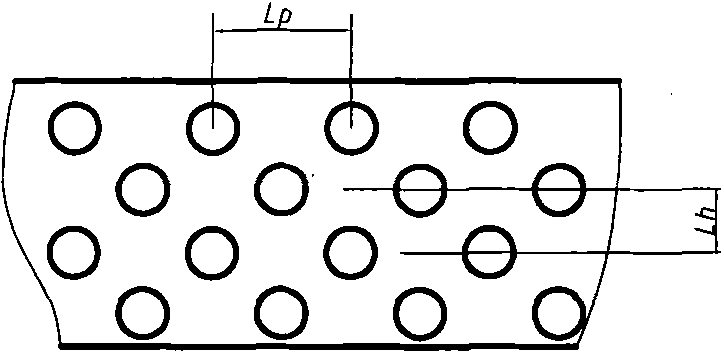

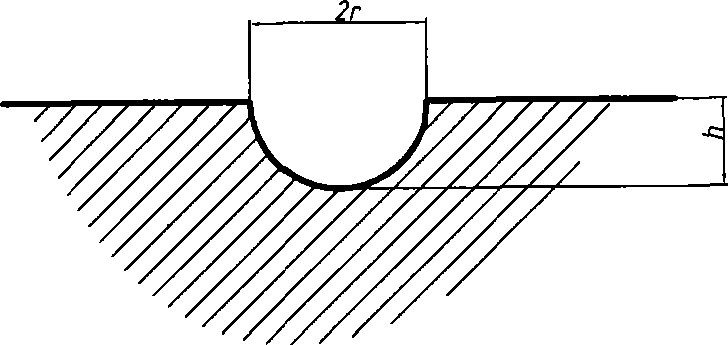

[0023] figure 1 It shows a schematic diagram of the global distribution state of the laser surface micro-modeling structure of a motorcycle cylinder liner according to the present invention. In the figure, the position line of piston 1 relative to the top dead center of cylinder liner 2 is line A, and the position line of bottom dead center is line B. The distance S between line A and line B is the stroke of the piston. In addition, the height of the piston is H; since the relative motion speed of piston 1 relative to cylinder liner 2 is very small near the top dead center, according to one of the three major conditions for the friction pair to form a lubricating oil film, that is, the motion pair must have a certain value of relative motion speed, and the test The demonstration of the results, plus this position is in the high temperature zone of the engine, so it is difficult for the piston 1, piston ring 3 and cylinder liner 2 to form a good lubricating oil film near the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com