Remote monitoring and controlling system for industrial grade photo bioreactor

A photobioreactor, remote monitoring technology, applied in photobioreactor, bioreactor/fermenter combination, general control system, etc., can solve the problems of low degree of automation, low measurement accuracy and precision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

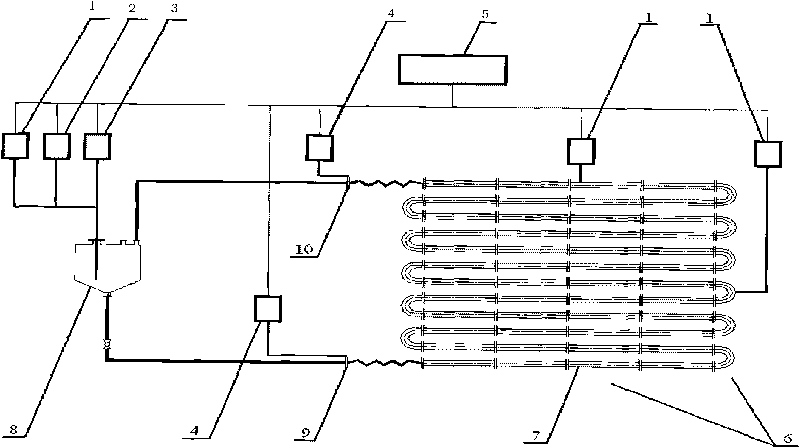

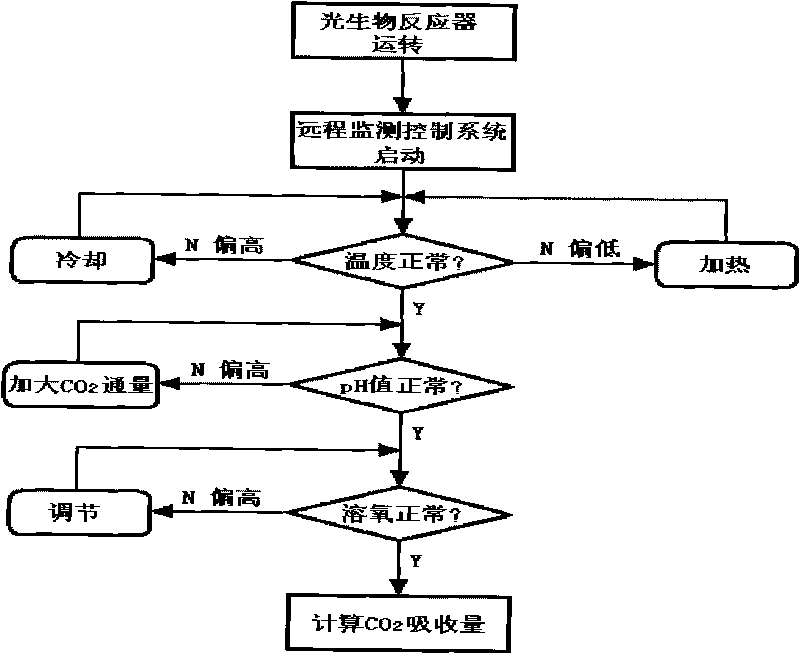

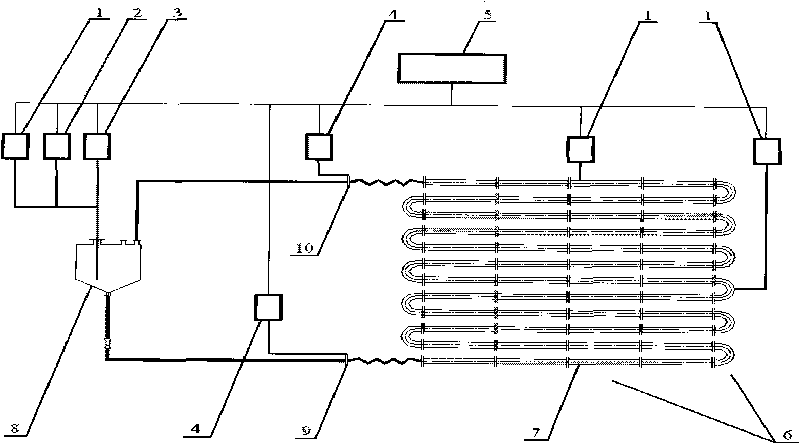

[0028] The structure of the remote monitoring control system of the present invention is mainly composed of a temperature detector 1, an online pH analyzer 2, an online dissolved oxygen analyzer 3, an online carbon dioxide analyzer 4 and other detection and analysis terminals and a remote control platform 5. There are several temperature detectors 1, one of which is inserted into the buffer tank 8 to monitor the temperature of the buffer tank, and the others are randomly distributed in the light area 7 of the photobioreactor 6. The probes of the online pH analyzer 2 and the online dissolved oxygen analyzer 3 are covered with plastic protective sleeves, inserted into the buffer tank 8 of the photobioreactor 6 through the manhole, below the liquid level of the culture medium, close to the bottom, so that more accurate measurement The current pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com