Packaging method and packaging structure of light emitting diode (LED) module

A packaging method and display module technology, applied in the direction of identification devices, instruments, electrical components, etc., can solve the problems of increasing manufacturing costs, affecting the first pass rate of LED display modules, separation, etc., to improve manufacturing quality, improve first pass rate, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

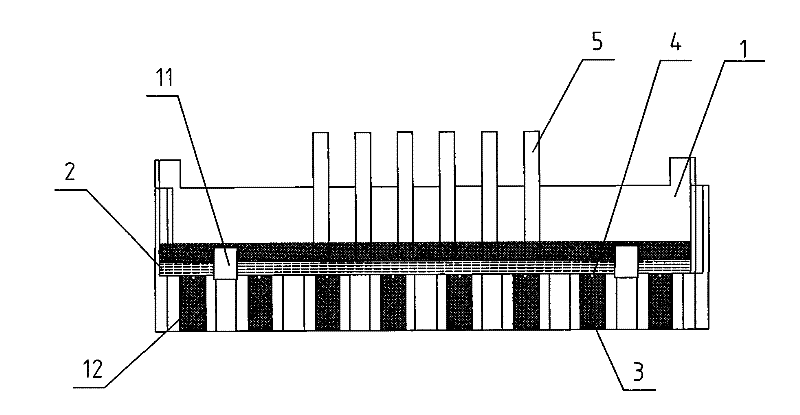

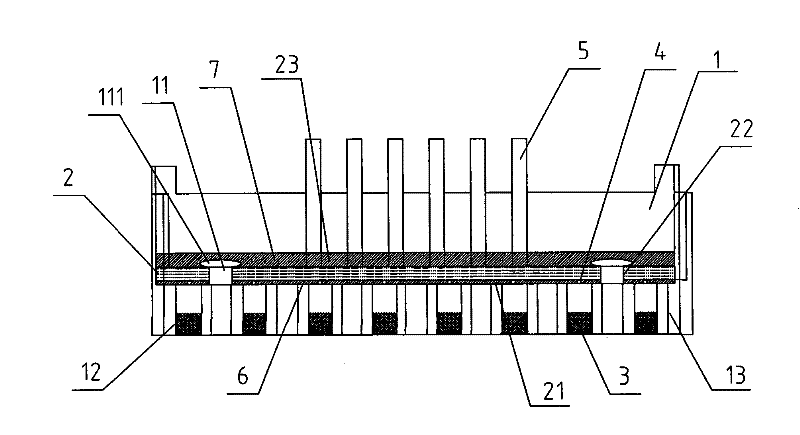

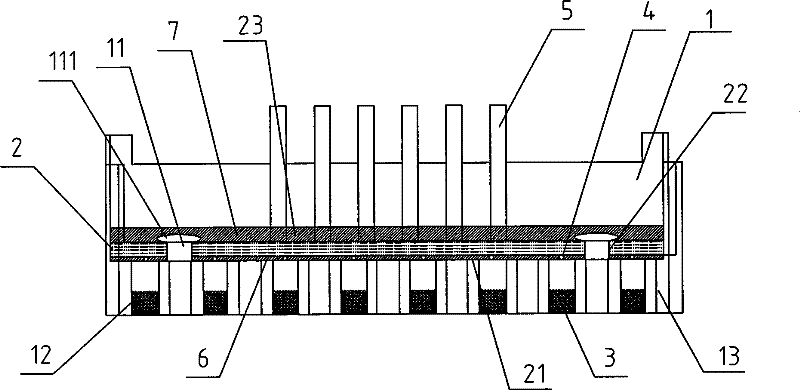

[0019] Such as figure 1 , figure 2 Shown, packaging method of the present invention comprises the following steps:

[0020] 1) Turn the display module cavity 1 upside down, inject epoxy resin 3 into each glue injection hole 12 on the panel of the display module cavity 1 with a syringe or other dispensing equipment, and pour the epoxy resin 3 with a thickness equal to the depth of the glue injection hole 12 1 / 2, bake and solidify;

[0021] 2) A plurality of LED chips 4 are bonded to the front surface 21 of the circuit board 2 with a die-bonding glue, and the first layer of silicone resin 6 is sprayed on the surface to form a transparent protective layer, which is baked and solidified;

[0022] 3) Put the circuit board 2 into the cavity 1 of the display module with the first layer of silicone resin 6 facing down and the pins 5 facing up, so that the pair of positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com