Anti-static protection structure and manufacturing method thereof

A technology of protection structure and manufacturing method, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as increasing production costs, and achieve the effect of preventing damage and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

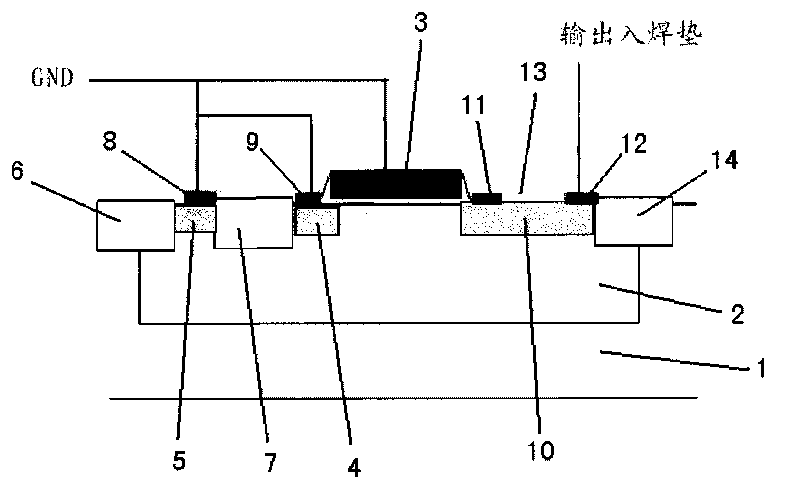

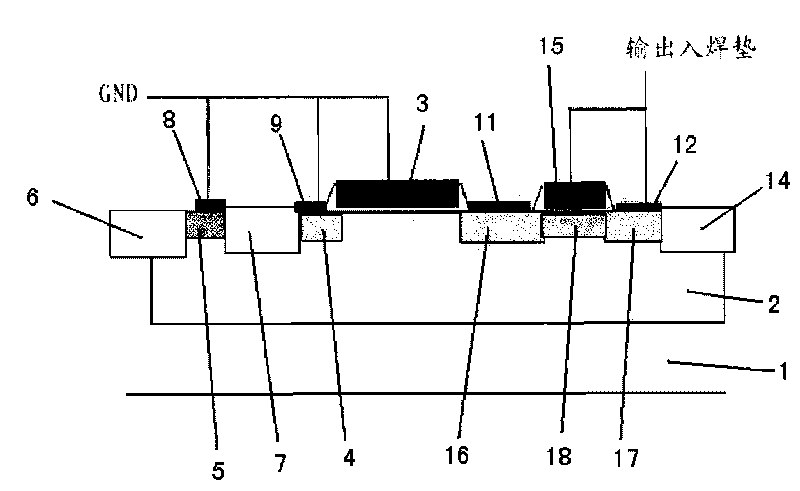

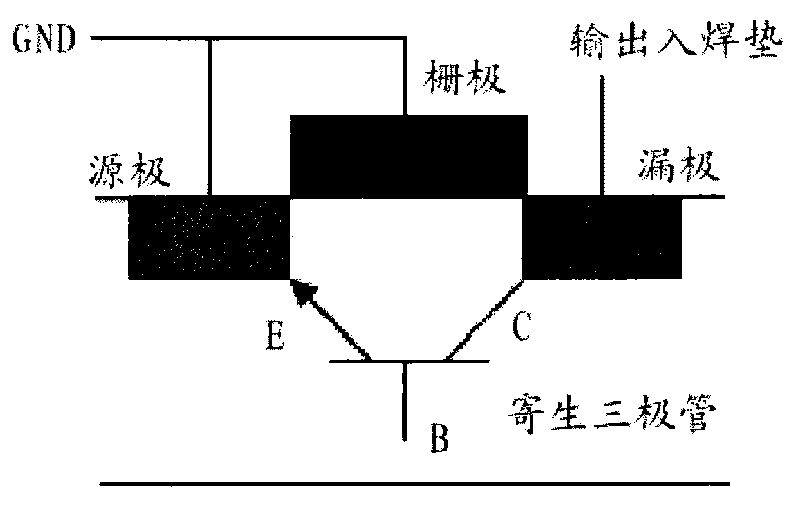

[0016] The invention discloses an antistatic protection structure, such as figure 2 As shown, it includes a P-type substrate 1 and a P well 2 on it. The P well 2 is provided with a first polysilicon gate 3, and the left side of the first polysilicon gate 3 is provided with a first N+ diffusion region 4, a P+ diffusion region 5 is also arranged on the left side of the first N+ diffusion region 4, a first field oxidation region 6 is arranged on the left side of the P+ diffusion region 5, and the P+ diffusion region 5 is connected to the first field oxidation region 5 A second field oxidation region 7 is separated between the first N+ diffusion regions 4, a first metal silicide 8 is arranged above the P+ diffusion region 5, and a second metal silicide is arranged above the first N+ diffusion region 4 9. The second metal silicide 9 is located on the left side of the first polysilicon gate 3, and the first metal silicide 8, the second metal silicide 9 and the first polysilicon gat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap