Case structure of outer rotor motor and rotor component made by case

一种外转子电机、壳体结构的技术,应用在磁路转动零部件、带有静止电枢和旋转磁体的同步电动机、电气元件等方向,能够解决加工麻烦、制造成本高、消耗能量等问题,达到生产加工容易、散热效果好、制造成本低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

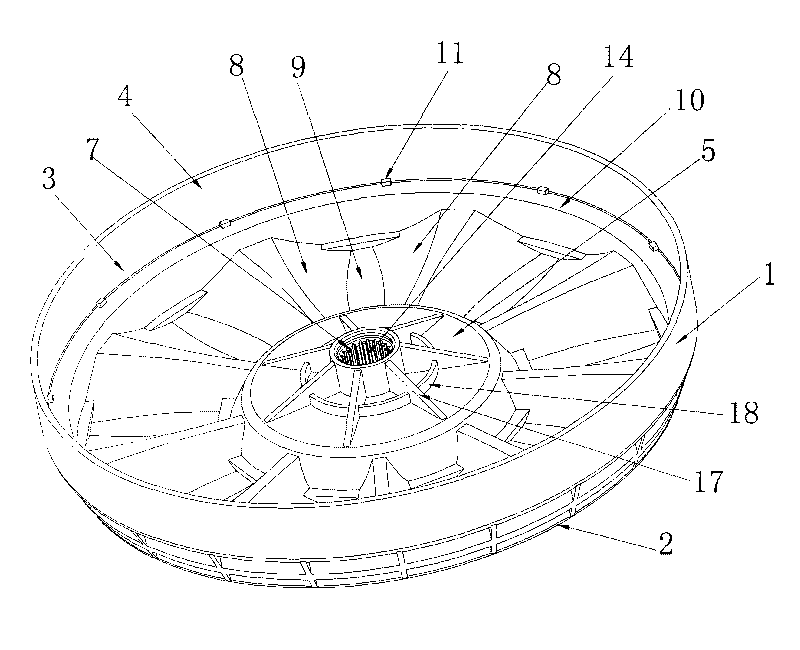

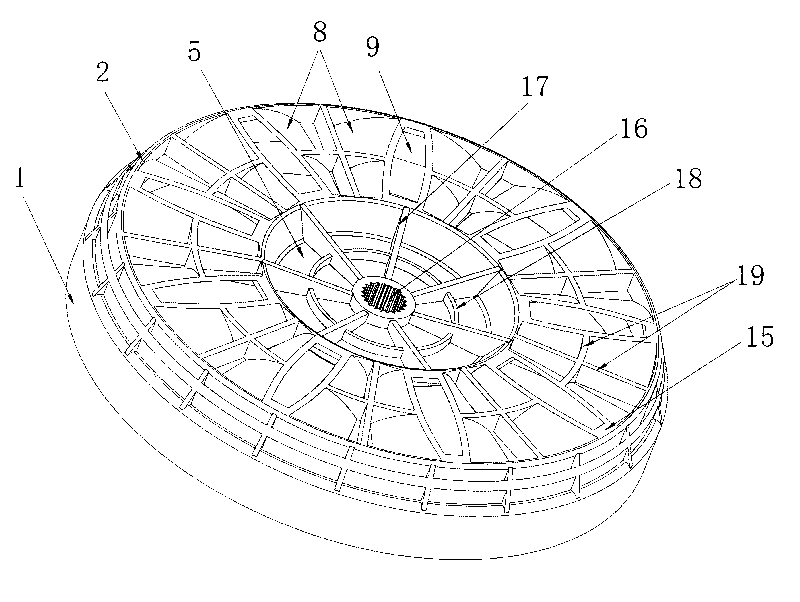

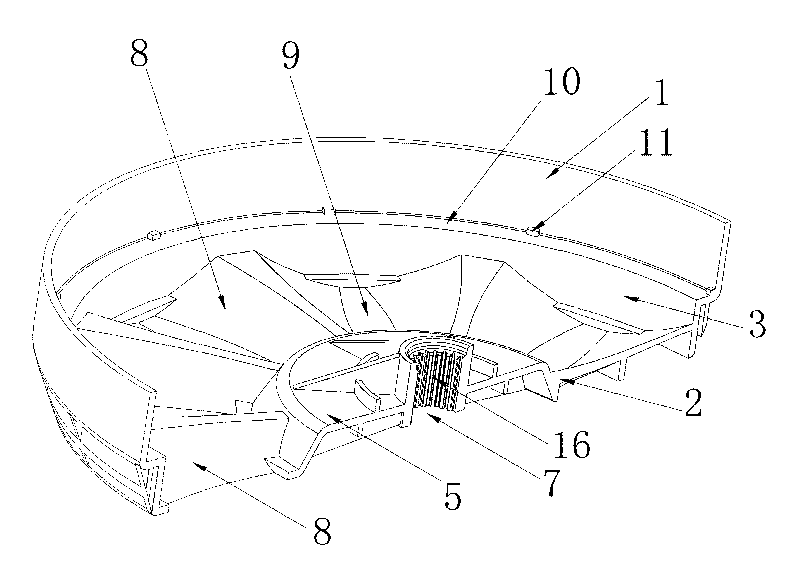

[0029] Such as Figure 1 to Figure 4 As shown, a housing structure of an outer rotor motor includes an annular outer wall 1 and an end cover 2 located at the bottom of the outer wall 1 , a cavity 3 is formed in the middle, an opening 4 is formed at the top, and a connection is formed at the center of the end cover 2 Seat 5, the center of the coupling seat 5 is provided with a keyway 7 connected to the motor drive shaft, the coupling seat 5 and the annular outer wall 1 are connected by a number of fan blades 8, and an air inlet 9 is formed between two adjacent fan blades 8 . The thickness in the middle of the fan blade 8 is the largest, and the thickness of the air inlets 9 on both sides decreases gradually from the middle, so that axial airflow can be generated when the housing rotates forward or reversed, and heat dissipation to the motor winding is formed. The middle part of the outer wall 1 forms an annular step 10, the surface of the step 10 protrudes several small bosses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com