Control circuit and method for flyback converter

A technology of control circuit and control method, which is applied in the direction of control/regulation system, conversion equipment with intermediate conversion to AC, instruments, etc., to achieve the effect of reducing switching loss, reducing switching times, and reducing ripples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

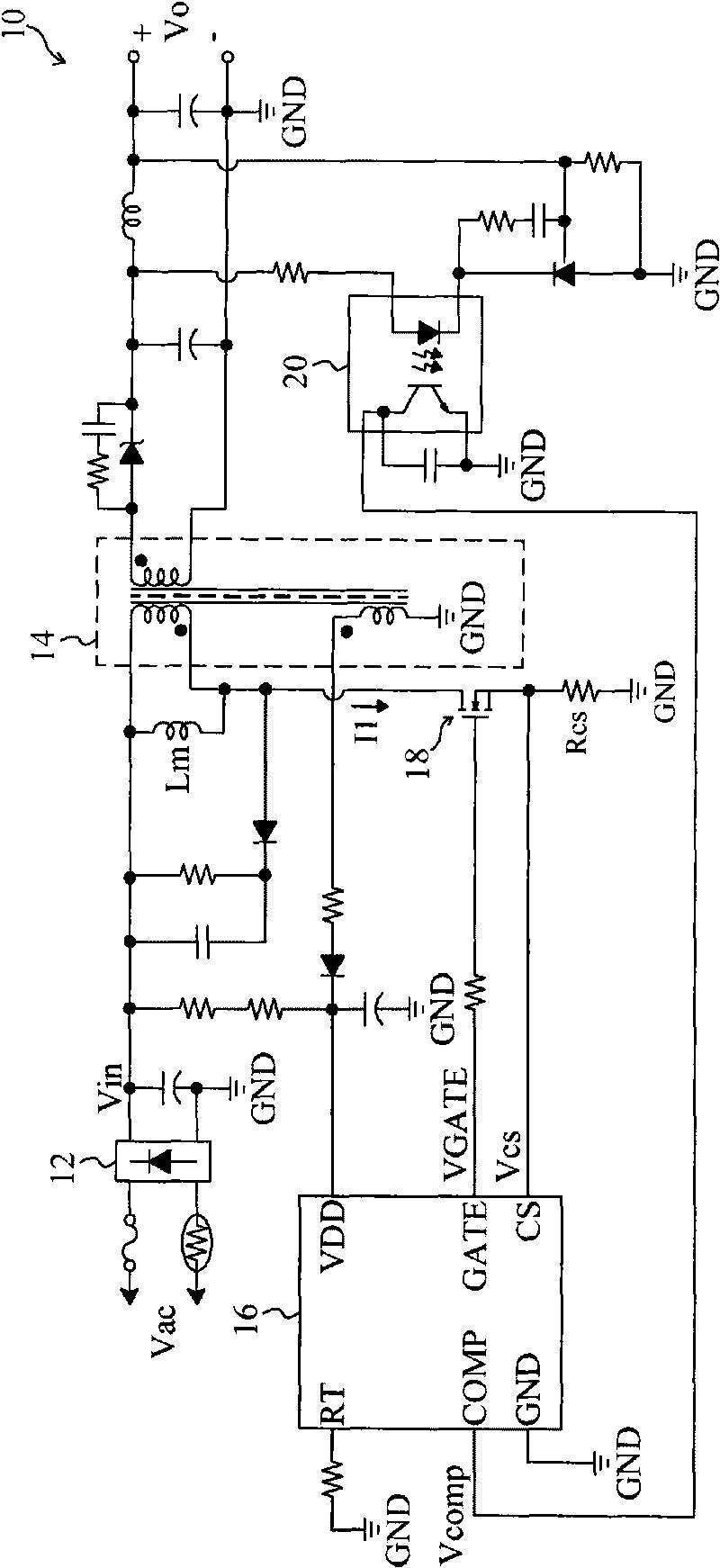

[0092] now please refer to figure 1 , those skilled in the art know the amount of change of the current sensing signal Vcs within a preset time Δton

[0093] ΔVcs=(Vin / Lm)×Δton×Rcs Formula 2

[0094] It can be seen from formula 2 that the variation ΔVcs of the current sensing signal Vcs is proportional to the input voltage Vin, so it is only necessary to multiply the variation ΔVcs of the current sensing signal Vcs by an appropriate coefficient

[0095] K=Tp / Δton Formula 3

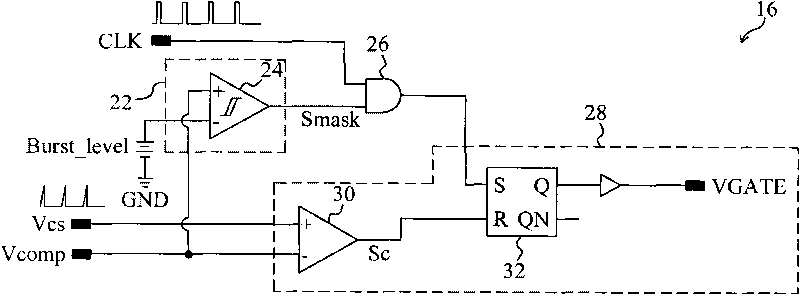

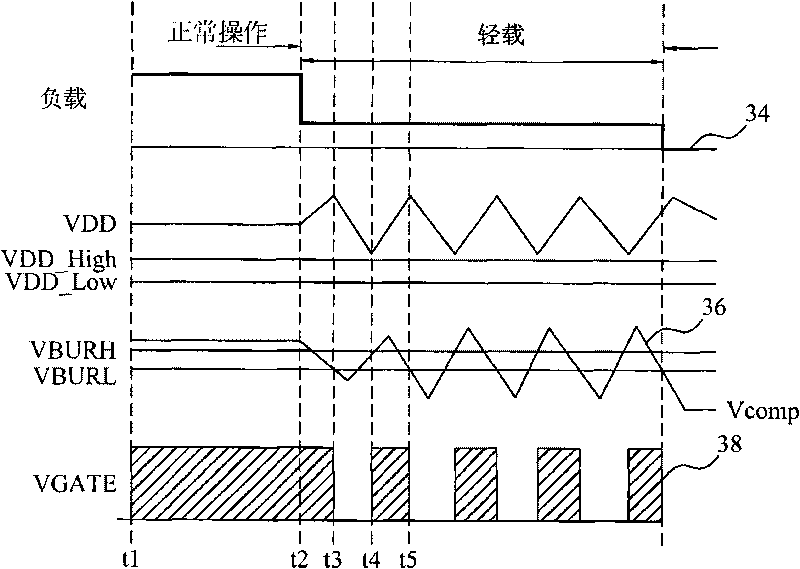

[0096] can eliminate the effect caused by the propagation delay in Equation 1 (Vin / Lm)×Tp, so that figure 1 The peak value of the current I1 on the primary side of the middle transformer 14 is almost the same regardless of whether the input voltage is high or low, thereby reducing noise. Figure 7 The first embodiment of the control circuit of the flyback power converter of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com