Quickly frozen meat filling steamed bun and production method thereof

A production method and steamed bread technology, which are applied in the field of quick-frozen meat-filled steamed bread and its production, can solve the problems of high cost, unstable quality and difficult quality of pastry chefs, and achieve the effects of enhancing product quality standardization and avoiding flavor loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

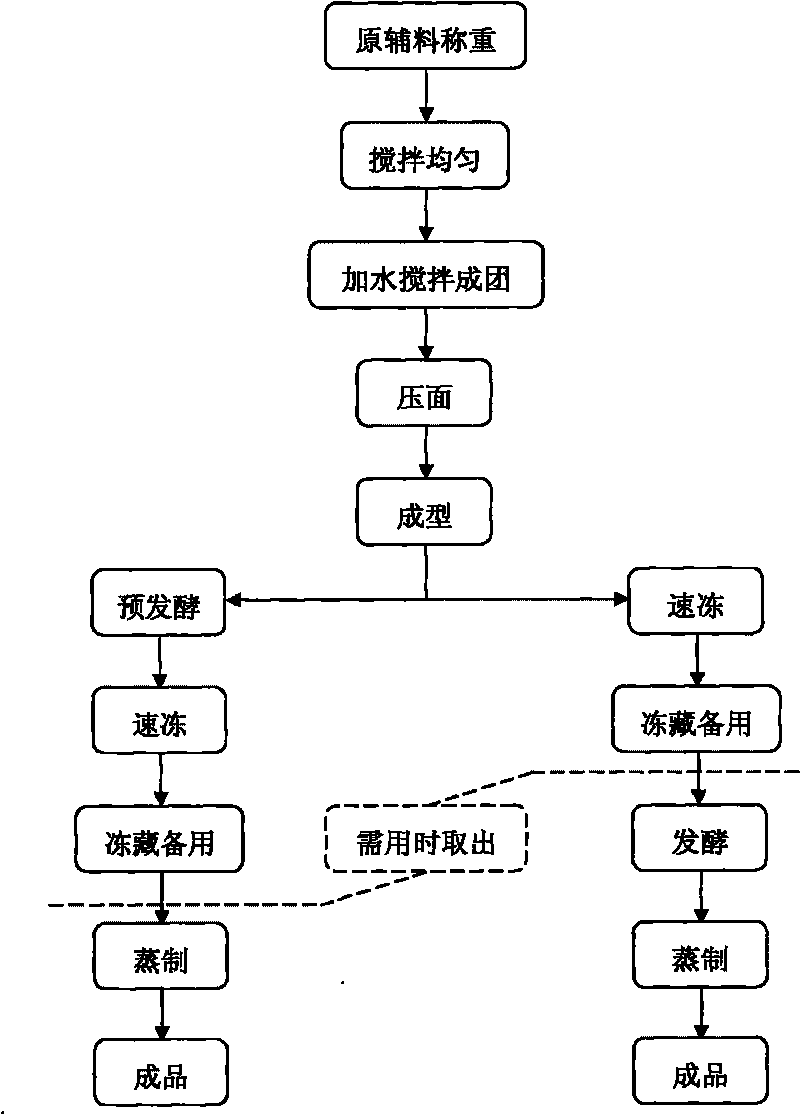

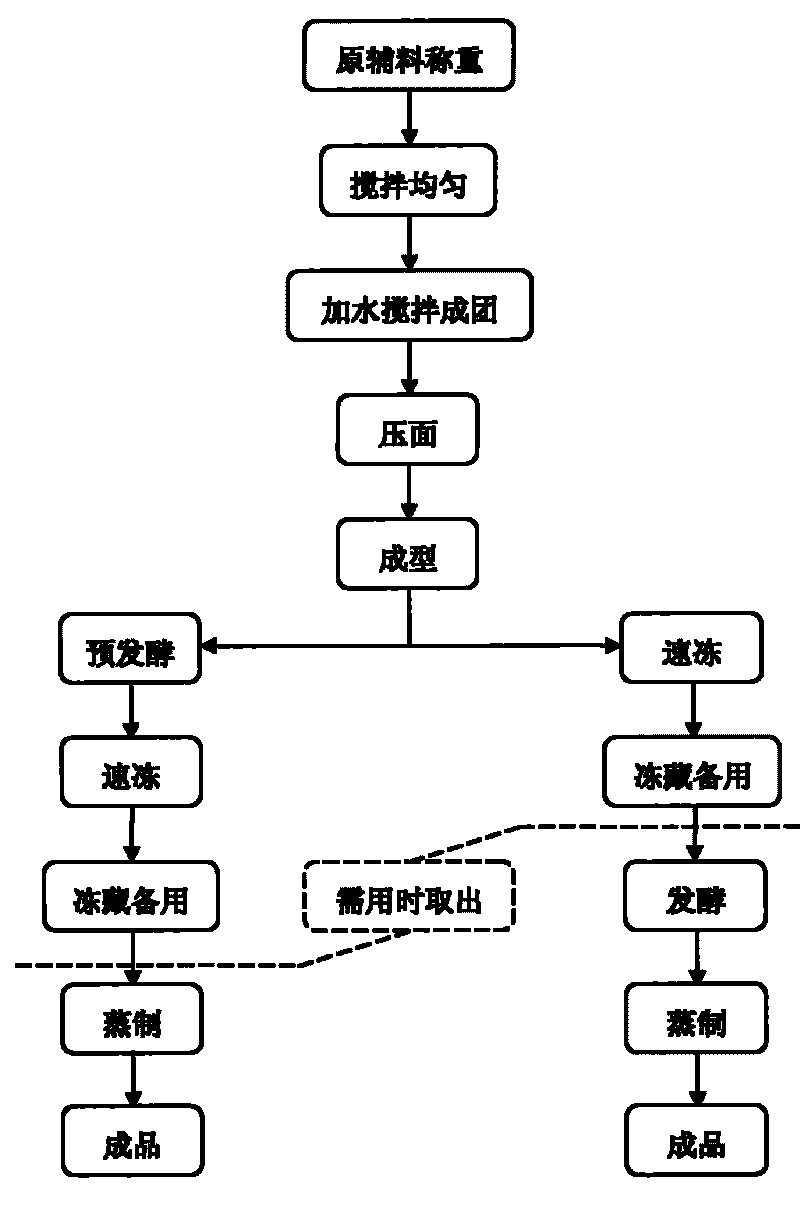

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: A quick-frozen steamed bun with meat stuffing and its production method adopts the following process steps, and its components are calculated in parts by weight:

[0022] First, 62 parts of flour, 0.7 parts of Yanshan yeast, 0.9 parts of aluminum-free baking powder, 0.8 parts of white sugar, 0.5 parts of shortening, 0.1 parts of salt, 0.09 parts of transglutaminase, 0.08 parts of lipase, and 0.08 parts of xylanase 0.08 parts of glucose oxidase, 0.12 parts of trehalose, 0.08 parts of ascorbic acid, 0.12 parts of lecithin, 0.36 parts of sucrose esters, 0.15 parts of glycerin, 0.06 parts of locust bean gum, 0.06 parts of artemisia gum, 0.06 parts of carboxymethyl cellulose , 0.06 parts of guar gum, 0.8 parts of gluten powder, and 0.8 parts of wheat starch were put into the mixing tank, stirred for 28 seconds, and the stirring speed was 50 rpm. Mix all kinds of materials, add 32 parts of water and stir slowly 3 minutes, the stirring speed is 50 rpm, and then m...

Embodiment 2

[0023] Embodiment 2: A quick-frozen steamed bun with meat stuffing and its production method adopts the following process steps, and its components are calculated in parts by weight:

[0024] First, 65 parts of flour, 0.5 parts of Yanshan yeast, 0.6 parts of aluminum-free baking powder, 0.5 parts of white sugar, 0.2 parts of shortening, 0.2 parts of salt, 0.06 parts of transglutaminase, 0.05 parts of lipase, and 0.05 parts of xylanase 0.05 parts of glucose oxidase, 0.08 parts of trehalose, 0.05 parts of ascorbic acid, 0.08 parts of lecithin, 0.24 parts of sucrose esters, 0.1 parts of glycerin, 0.04 parts of locust bean gum, 0.04 parts of artemisia gum, 0.04 parts of carboxymethyl cellulose , 0.04 parts of guar gum, 0.54 parts of gluten powder, and 0.54 parts of cornstarch were put into the mixing tank, stirred at a slow speed for 32 seconds, and the stirring speed was 60 rpm. Stir at high speed for 5 minutes at a speed of 60 rpm, then stir at a medium speed for 10 minutes to f...

Embodiment 3

[0025] Embodiment 3: A kind of quick-frozen steamed bun with meat stuffing and its production method, the following process steps are adopted, and its components are counted in parts by weight:

[0026] First, 64 parts of flour, 0.8 parts of Yanshan yeast, 0.8 parts of aluminum-free baking powder, 0.6 parts of white sugar, 0.4 parts of shortening, 0.3 parts of salt, 0.08 parts of transglutaminase, 0.07 parts of lipase, and 0.07 parts of xylanase 0.07 parts of glucose oxidase, 0.1 parts of trehalose, 0.07 parts of ascorbic acid, 0.1 parts of lecithin, 0.3 parts of sucrose esters, 0.14 parts of glycerin, 0.05 parts of locust bean gum, 0.05 parts of artemisia gum, 0.05 parts of carboxymethyl cellulose , 0.05 parts of guar gum, 0.7 parts of gluten powder, and 0.7 parts of potato starch were put into the mixing tank, stirred at a slow speed for about 30 seconds, and the stirring speed was 70 rpm, mixed all kinds of materials, and added 30.5 parts of water Stir at low speed for 2 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com