Inorganic pigment color paste and preparing method thereof

A technology of inorganic pigments and color pastes, applied in the direction of pigment pastes, latex paints, etc., can solve the problems of poor moisturizing performance of color pastes, difficulty in commercialization, and inapplicability, achieve good storage stability, and facilitate industrial production and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

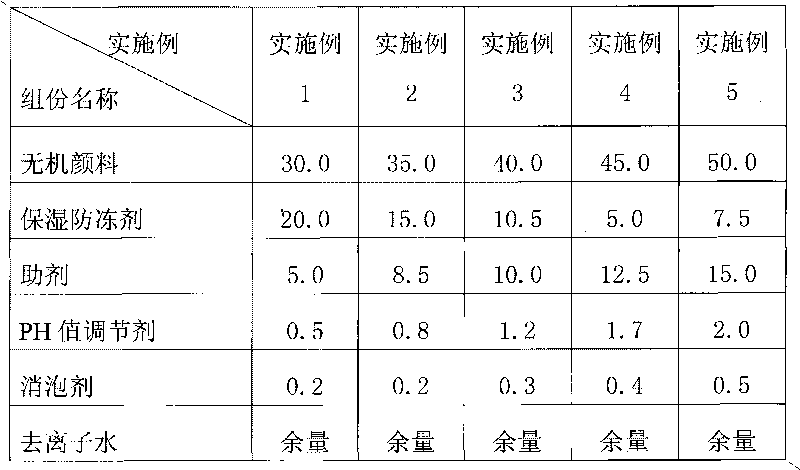

[0029] The formula of the embodiment of the invention is referring to Table 1:

[0030] Table 1: (unit: weight percentage)

[0031]

[0032] According to above-mentioned prescription, preparation method carries out as follows:

[0033] ①. Add deionized water, moisturizing antifreeze and additives into the mixer and disperse for 15 minutes at a speed of 300-800r / min (300-800 revolutions per minute) to obtain a uniformly mixed solution;

[0034] ②. Add all the inorganic pigments into the homogeneously mixed solution obtained in step ①, disperse at a speed of 2000-3000r / min (2000-3000 rpm) for 30 minutes or more, and slowly add a pH regulator during the dispersion process , to obtain premixed inorganic pigment paste;

[0035] ③. Grinding the pre-mixed inorganic pigment color paste obtained in step ②, and stop grinding when the fineness is ≤20.0 μm to obtain the initial inorganic pigment color paste;

[0036] ④. After carrying out quality inspection, vacuum defoaming and fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com