Guide flow type thermal evaporation depositing device

A deposition device and thermal evaporation technology, applied in the field of thermal evaporation thin film preparation, can solve problems such as inapplicable applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing

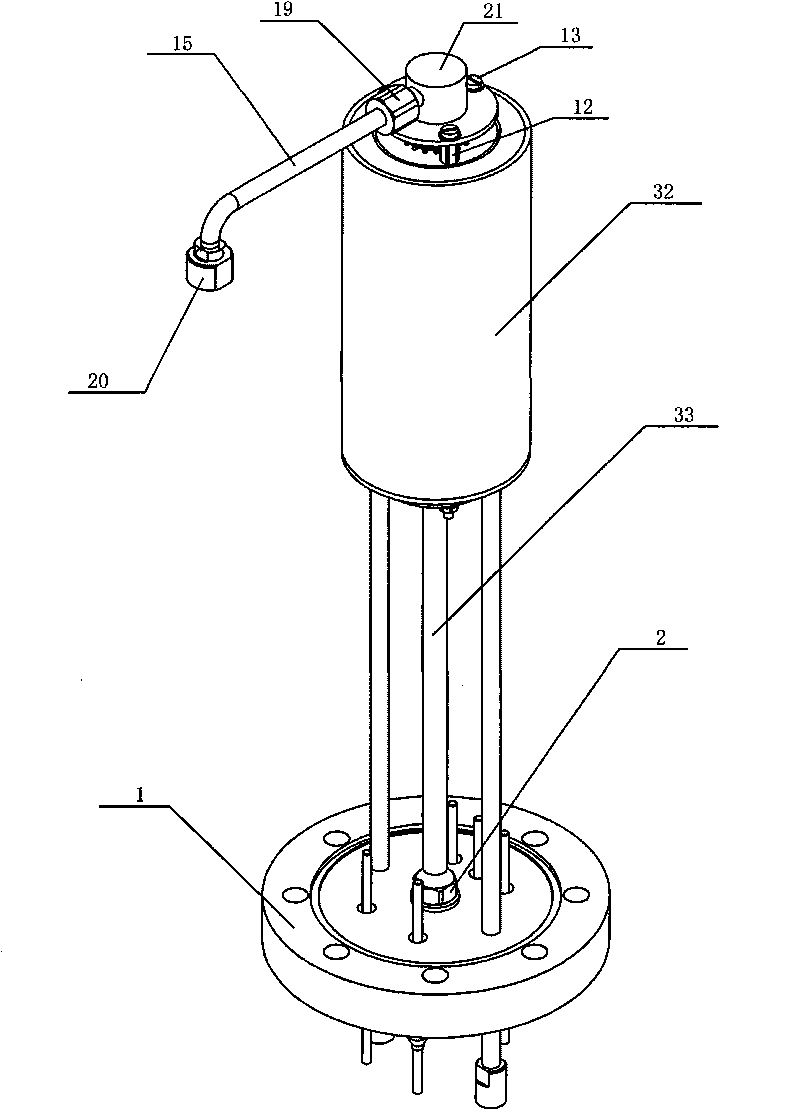

[0028] figure 1 It is a schematic diagram of the overall appearance of the diversion type thermal evaporation deposition device of the present invention. In the figure, the heating furnace 32 is fixedly arranged on the base flange 1 through the central axis 33, and the draft tube base 21 arranged on the top of the heating furnace 32 is connected through the connecting nut 19 is fixedly connected with the guide tube 15, and the top end of the guide tube 15 is provided with a nozzle cap 20.

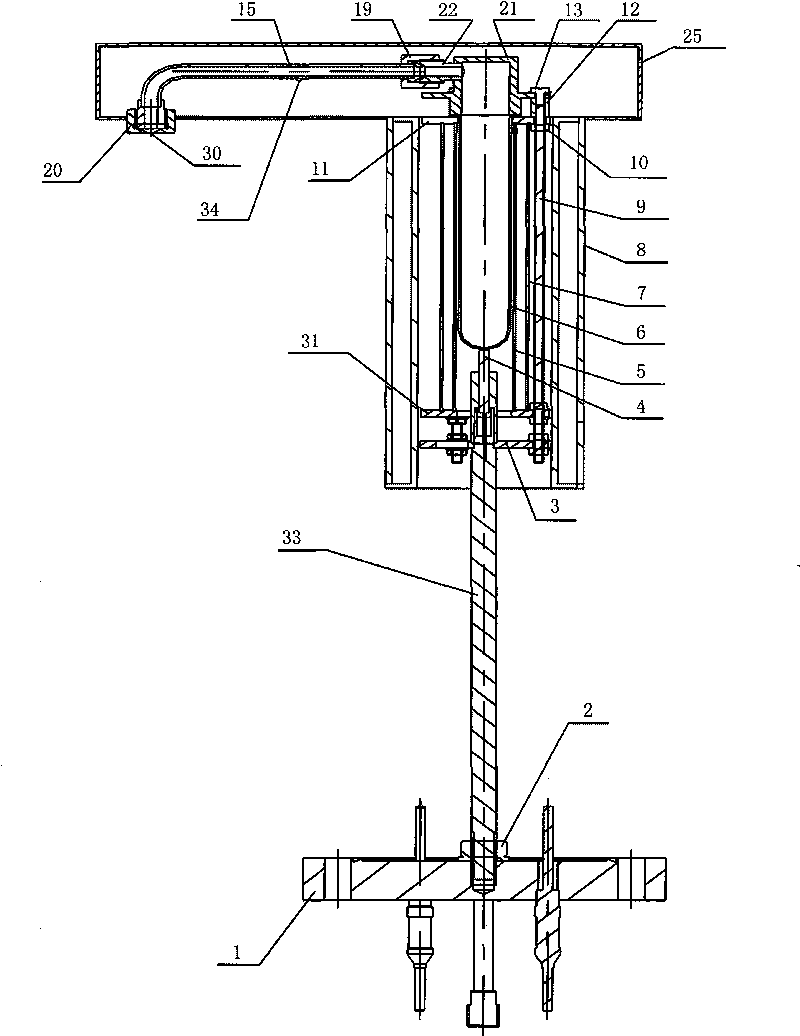

[0029] Figure 2-6 Among them, a diversion type thermal evaporation deposition device of the present invention includes a heating furnace 32, a draft tube 15 and a draft tube heating cover 25; the heating furnace 32 takes the central axis 33 as the center, and passes through the The heating wire frame 5 that is set, the inner insulation cylinder 7 and the outer insulation cylinder 8 con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap